Are you gearing up for a career in Filing Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Filing Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

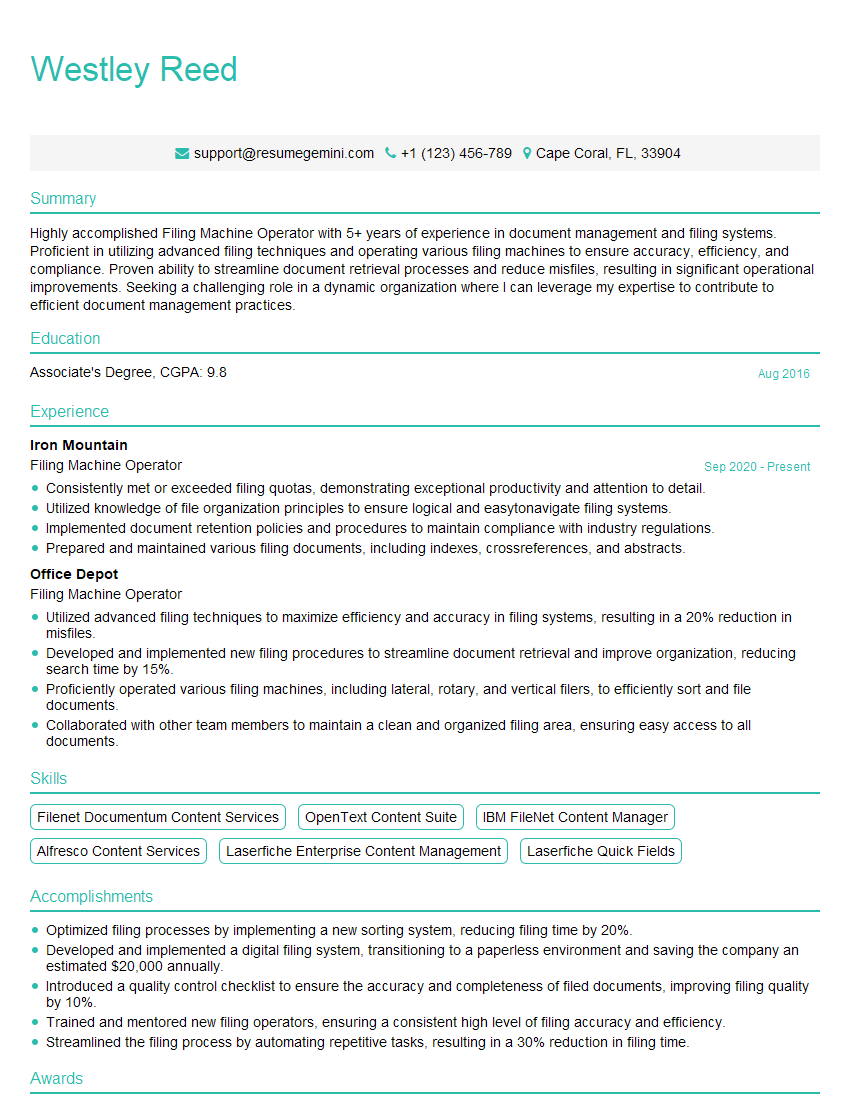

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filing Machine Operator

1. Explain the process of calibrating a filing machine?

Calibration is a crucial step in ensuring the accuracy and precision of a filing machine. Here’s the process I follow:

- Set up reference pieces: I use precision-machined parts as reference pieces to compare the machine’s output.

- Adjust machine parameters: Using a calibration tool or software, I adjust the machine’s speed, feed rate, and other parameters to match the reference pieces.

- Run test cuts: I make test cuts and compare them to the reference pieces using measuring instruments like calipers and micrometers.

- Fine-tune adjustments: Based on the comparison, I make fine adjustments to the machine parameters until the test cuts meet the specified tolerances.

- Verify calibration: I run additional test cuts to ensure the machine is consistently producing accurate parts.

2. Describe how to troubleshoot a filing machine that is producing parts with burrs?

Identifying the Cause

- File condition: Check the file for wear, damage, or incorrect cutting angle.

- Workpiece material: Some materials, such as hardened steel, may require a specialized file or cutting fluid.

- Machine settings: Ensure that the speed and feed rate are optimal for the material and file combination.

Resolving the Issue

- Sharpen or replace the file: If the file is worn or damaged, it must be sharpened or replaced.

- Adjust machine settings: Optimize the speed and feed rate to reduce burr formation.

- Use cutting fluid: Lubricating the cutting process can help reduce burrs.

- Check file alignment: Ensure that the file is properly aligned with the workpiece to minimize burrs.

3. What safety measures should be taken when operating a filing machine?

Operating a filing machine requires strict adherence to safety protocols:

- Wear appropriate PPE: Safety glasses, earplugs, and gloves are essential to protect against flying debris, noise, and sharp edges.

- Secure the workpiece: Proper clamping or fixturing ensures the workpiece is held firmly in place, preventing movement or ejection.

- Maintain a clean work area: Clean up metal shavings and debris regularly to avoid tripping or slipping hazards.

- Inspect the machine regularly: Check for loose connections, damaged components, or excessive wear to prevent accidents.

- Follow lockout/tagout procedures: Isolate the machine from power sources before performing any maintenance or repairs.

4. How do you calculate the optimal feed rate for a filing machine?

The optimal feed rate depends on several factors:

- File type: Different files have specific cutting rates.

- Workpiece material: Harder materials require slower feed rates.

- Desired surface finish: Finer finishes require slower feed rates.

The formula for calculating feed rate is:

Feed Rate = Cutting Speed / Number of Cuts per Inch

Where:

- Cutting speed is typically provided by the file manufacturer.

- Number of cuts per inch refers to the desired surface roughness.

5. What types of files are used for different materials?

The type of file used depends on the material being filed:

- Soft metals (aluminum, copper, brass): Single-cut or double-cut files with coarse teeth.

- Hard metals (steel): Double-cut files with finer teeth.

- Stainless steel: Special files with hard teeth and aggressive cutting angles.

- Wood: Rasps or files with larger, angled teeth.

- Plastics: Files with fine, pointed teeth or diamond-coated abrasives.

6. Describe the maintenance procedures for a filing machine?

Regular maintenance is crucial for optimal performance:

- Clean and lubricate: Remove metal shavings, clean the machine with a solvent, and lubricate moving parts.

- Inspect and replace brushes: Check carbon brushes regularly and replace them when worn.

- Check and tighten bolts: Ensure all bolts and connections are tight to prevent vibrations and misalignment.

- Sharpen or replace files: Inspect files for wear and damage, and sharpen or replace them as needed.

- Follow manufacturer’s instructions: Refer to the machine’s manual for specific maintenance guidelines.

7. How do you set up a filing machine for a specific job?

Proper setup ensures efficient and accurate filing:

- Select the appropriate file: Choose the correct type of file for the material and desired finish.

- Secure the workpiece: Clamp or fixture the workpiece securely to prevent movement or vibration.

- Set the machine parameters: Adjust the speed, feed rate, and stroke length as per the material and file combination.

- Align the file: Ensure the file is properly aligned with the workpiece to achieve optimal cutting.

- Test run: Conduct a test cut to verify the settings and make any necessary adjustments.

8. What is the purpose of a coolant in filing operations?

Coolant plays several important roles in filing:

- Lubrication: Coolant reduces friction between the file and the workpiece, extending tool life and improving surface finish.

- Cooling: Filing generates heat, and coolant helps dissipate this heat, preventing workpiece distortion and file damage.

- Chip removal: Coolant helps flush away metal shavings, keeping the cutting surface clean and improving efficiency.

- Corrosion protection: Coolants often contain additives that protect the workpiece from corrosion.

9. How do you adjust the stroke length on a filing machine?

Adjusting the stroke length is crucial for optimizing filing efficiency:

- Identify the adjustment mechanism: Locate the knob or lever that controls stroke length.

- Loosen the lock: There may be a locking mechanism that needs to be loosened before adjusting.

- Set the desired stroke length: Rotate the knob or lever to the desired stroke length setting.

- Tighten the lock: Once the stroke length is set, retighten the lock to secure the adjustment.

- Test run: Conduct a test cut to verify the stroke length and make any necessary fine-tuning.

10. What is the importance of maintaining proper tension on the file?

Proper file tension ensures efficient and precise filing:

- Optimal cutting action: Correct tension allows the file to cut effectively without chattering or vibration.

- Extended file life: Maintaining proper tension prevents premature wear and breakage of the file.

- Reduced operator fatigue: A properly tensioned file requires less effort to use, reducing operator fatigue.

- Improved surface finish: Proper tension minimizes file chatter, resulting in a smoother and more consistent surface finish.

- Accurate filing: Correct tension ensures that the file maintains its shape and angle, allowing for accurate and precise filing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Filing Machine Operators play a crucial role in the smooth and efficient functioning of offices, warehouses, and manufacturing facilities. They are responsible for operating filing machines to file, retrieve, and organize documents and other materials, ensuring the accuracy and accessibility of vital information.

1. Filing and Retrieval of Documents

Filing Machine Operators are primarily responsible for filing and retrieving documents using filing machines. They use their knowledge of filing systems to ensure that documents are stored and retrieved quickly and accurately. This includes:

- Sorting and organizing documents according to established filing systems.

- Operating filing machines to file and retrieve documents efficiently.

2. Maintenance and Inspection of Filing Equipment

Filing Machine Operators are responsible for maintaining and inspecting filing machines to ensure their proper functioning. This includes:

- Cleaning and lubricating filing machines regularly.

- Inspecting filing machines for any signs of wear or damage.

- Reporting any issues or malfunctions to the appropriate personnel.

3. Compliance with Filing Procedures

Filing Machine Operators must comply with established filing procedures to maintain the integrity and accuracy of filed documents. This includes:

- Following established filing conventions and guidelines.

- Using proper filing materials and supplies.

- Maintaining up-to-date filing records.

4. Document Security and Confidentiality

Filing Machine Operators are responsible for maintaining the security and confidentiality of filed documents. This includes:

- Storing and retrieving documents in secure locations.

- Limiting access to confidential documents to authorized personnel.

Interview Tips

Preparing thoroughly for a Filing Machine Operator interview is essential. Here are some tips to help you ace the interview and demonstrate your skills and qualifications:

1. Research the Company and Role

Before the interview, take some time to research the company you’re applying to and the specific Filing Machine Operator role. This will give you a good understanding of the company’s culture, values, and the specific responsibilities of the position. You can find this information on the company’s website, LinkedIn page, and other online sources.

2. Practice Answering Common Interview Questions

There are certain common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this role?” Practice answering these questions in a clear and concise way that highlights your skills and experience.

3. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. Prepare a few questions about the company, the role, or the industry. This will give you an opportunity to learn more about the company and the position, and it will also show the interviewer that you’re genuinely interested in the opportunity.

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally for your interview. Arrive on time for your interview, and be polite and respectful to everyone you meet.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Filing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.