Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Finish Opener position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

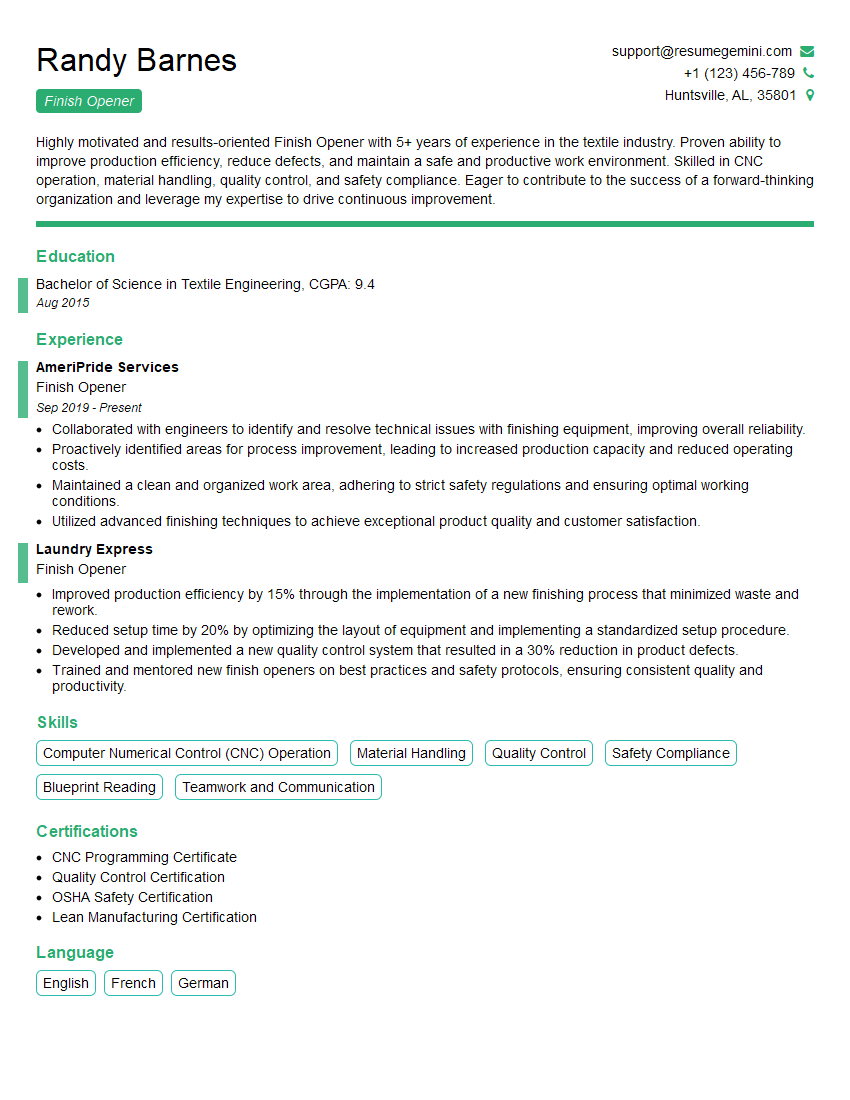

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Finish Opener

1. What are the key safety precautions you take when using a finishing opener?

As a Finish Opener, I prioritize safety by adhering to the following precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a mask, to minimize exposure to dust and debris.

- Ensure the machine is properly grounded and inspected before operation to prevent electrical hazards.

- Keep the work area clean and free of tripping hazards by regularly sweeping and removing excess materials.

- Maintain a safe distance from the point of operation to avoid contact with moving parts.

- Never attempt to remove jammed fabric or debris while the machine is running, as this can cause severe injury.

2. How do you ensure the quality of the finished product when opening fabric?

Maintaining Sharp Blades

- Regularly inspect blades for sharpness and replace them promptly when necessary to ensure clean and accurate cuts.

- Use the appropriate blade type and size for the specific fabric being processed.

Proper Fabric Alignment

- Carefully align the fabric before opening to prevent uneven or skewed cuts.

- Utilize guides or templates to ensure consistent and precise positioning.

Tension and Speed Control

- Adjust the machine’s tension and speed settings to match the fabric type and thickness.

- Avoid excessive tension, as this can stretch or damage the fabric.

- Operate the machine at an appropriate speed to prevent tearing or fraying.

3. What techniques do you employ to minimize fabric waste during the opening process?

To minimize fabric waste, I implement the following techniques:

- Plan the cutting layout carefully to maximize fabric utilization and minimize scraps.

- Use sharp blades and ensure proper alignment to reduce the risk of uneven or inaccurate cuts.

- Explore the use of spreaders or other equipment to evenly distribute the fabric, reducing the need for trimming excess.

- Consider recycling or repurposing fabric scraps for other projects, such as patchwork or sample making.

- Train and supervise team members to handle fabric efficiently and minimize waste throughout the process.

4. Explain the process of preparing a fabric roll for the opening machine.

Preparing a fabric roll for the opening machine involves the following steps:

- Inspect the fabric roll for any tears, holes, or damage and report any issues promptly.

- Remove the packaging and secure the fabric roll on the unwind stand or creel.

- Check the fabric width and tension settings to ensure they are appropriate for the opening machine.

- Thread the fabric through the machine’s guides and tensioners, ensuring it is aligned correctly.

- Make sure the machine is properly adjusted for the fabric type and weight to achieve the desired opening results.

5. How do you troubleshoot common problems encountered during the opening process?

Blade Issues

- Dull or damaged blades: Replace blades as needed to ensure clean and accurate cuts.

- Improper blade adjustment: Adjust blades according to the fabric type and thickness to optimize performance.

Fabric Feeding Issues

- Uneven fabric tension: Adjust tension settings to ensure fabric is fed smoothly through the machine.

- Fabric misalignment: Check fabric alignment and adjust guides or templates as necessary.

Machine Malfunctions

- Electrical faults: Check power supply and electrical connections for any issues.

- Mechanical problems: Inspect gears, belts, and other components for wear or damage.

6. Describe the different types of opening machines and their applications.

Roller Opener

- Suitable for loose and bulky fabrics, such as cotton and wool.

- Uses rotating rollers to gently open and separate fibers.

Cylinder Opener

- Ideal for synthetic fabrics, blends, and coarse materials.

- Features a cylinder with teeth or pins to remove impurities and untangle fibers.

Carding Machine

- Used for fine fibers, such as wool and cashmere.

- Employs a series of rollers covered with fine wires to align and remove impurities, creating a more uniform fiber mass.

7. What factors influence the selection of the appropriate opening machine for a particular fabric?

- Fabric type: Different fabrics have varying fiber characteristics and require specific opening techniques.

- Fabric weight and density: Heavier or denser fabrics may need more aggressive opening to separate fibers.

- Desired level of opening: The extent to which fibers need to be separated depends on the subsequent processing steps.

- Production capacity: The speed and efficiency of the machine should align with the production requirements.

- Cost and availability: Consider the cost of the machine and its availability within the budget and production schedule.

8. How do you ensure the proper maintenance and calibration of finishing openers?

- Regular cleaning: Remove dust, lint, and debris from the machine to prevent buildup and ensure smooth operation.

- Blade inspection and sharpening: Check blades for sharpness and replace or sharpen them as necessary to maintain optimal cutting performance.

- Tension adjustment: Calibrate tension settings to match the fabric type and weight, ensuring proper opening and minimizing fabric damage.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations to reduce wear and tear.

- Safety checks: Conduct regular safety inspections to ensure the machine is operating safely and in compliance with regulations.

9. What quality control measures do you implement to ensure the consistency of the finished product?

- Fabric inspection: Inspect fabric before and after opening to identify any defects or inconsistencies.

- Sample testing: Conduct regular sample testing to assess the opening quality and make adjustments as necessary.

- Process monitoring: Monitor the opening process closely to ensure parameters such as tension, speed, and temperature are within acceptable ranges.

- Data collection and analysis: Collect data on opening results, such as fiber length and uniformity, to track performance and identify areas for improvement.

- Regular calibration: Calibrate the opening machine regularly to maintain precision and accuracy.

10. How do you stay updated with the latest advancements and best practices in the field of fabric opening?

- Industry trade shows and conferences: Attend industry events to learn about new technologies and connect with experts.

- Technical publications and journals: Read industry publications and journals to stay informed about research and best practices.

- Online resources: Utilize online resources, such as webinars and whitepapers, to access the latest information.

- Collaboration with peers: Network with other professionals in the field to share knowledge and experiences.

- Training and certification: Participate in training programs and certifications to enhance skills and stay current with industry standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Finish Opener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Finish Opener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Finish Openers play a vital role in the manufacturing process by ensuring that materials are prepared for efficient production. Key responsibilities typically include:

1. Receiving and Inspecting Materials:

Receiving incoming raw materials and inspecting them for quality, quantity, and damage.

2. Unloading and Storing Materials:

Unloading materials from trucks or other transportation vehicles and storing them in designated areas.

3. Opening and Unpacking Materials:

Opening and unpacking materials, such as rolls of fabric, boxes of components, or drums of chemicals.

4. Preparing Materials for Production:

Preparing materials for production by cutting, folding, or otherwise shaping them to meet specifications.

5. Maintaining Clean and Organized Work Area:

Maintaining a clean and organized work area to ensure efficient operations and safety.

6. Operating Equipment:

Operating various equipment, such as forklifts, cutters, and scales, to perform job duties.

7. Monitoring Production Process:

Monitoring the production process to identify and address any issues that may affect the quality of the finished product.

8. Adhering to Safety Regulations:

Adhering to all safety regulations and guidelines to maintain a safe working environment.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some effective tips and hacks to help you ace your interview for a Finish Opener position:

1. Research the Company and Position:

Before the interview, take the time to thoroughly research the company and the specific Finish Opener position you are applying for. This will give you a good understanding of the company’s culture, values, and the specific requirements of the role.

2. Practice Your Answers:

Take some time to prepare your answers to common interview questions. Consider questions related to your experience, skills, and why you are interested in the position. Practicing your answers will help you feel more confident and articulate during the interview.

3. Dress Professionally:

First impressions matter, so it is important to dress professionally for your interview. This shows the interviewer that you are serious about the position and respectful of their time.

4. Arrive on Time:

Punctuality is essential for any interview. Aim to arrive a few minutes early to allow yourself time to settle in and prepare for the interview.

5. Be Enthusiastic and Positive:

Throughout the interview, maintain a positive and enthusiastic attitude. This will show the interviewer that you are genuinely interested in the position and eager to contribute to the team.

6. Ask Thoughtful Questions:

Towards the end of the interview, take the opportunity to ask thoughtful questions about the company, the position, and the team. This demonstrates your engagement and interest in the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Finish Opener, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Finish Opener positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.