Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Honing Machine Set-Up Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Honing Machine Set-Up Operator so you can tailor your answers to impress potential employers.

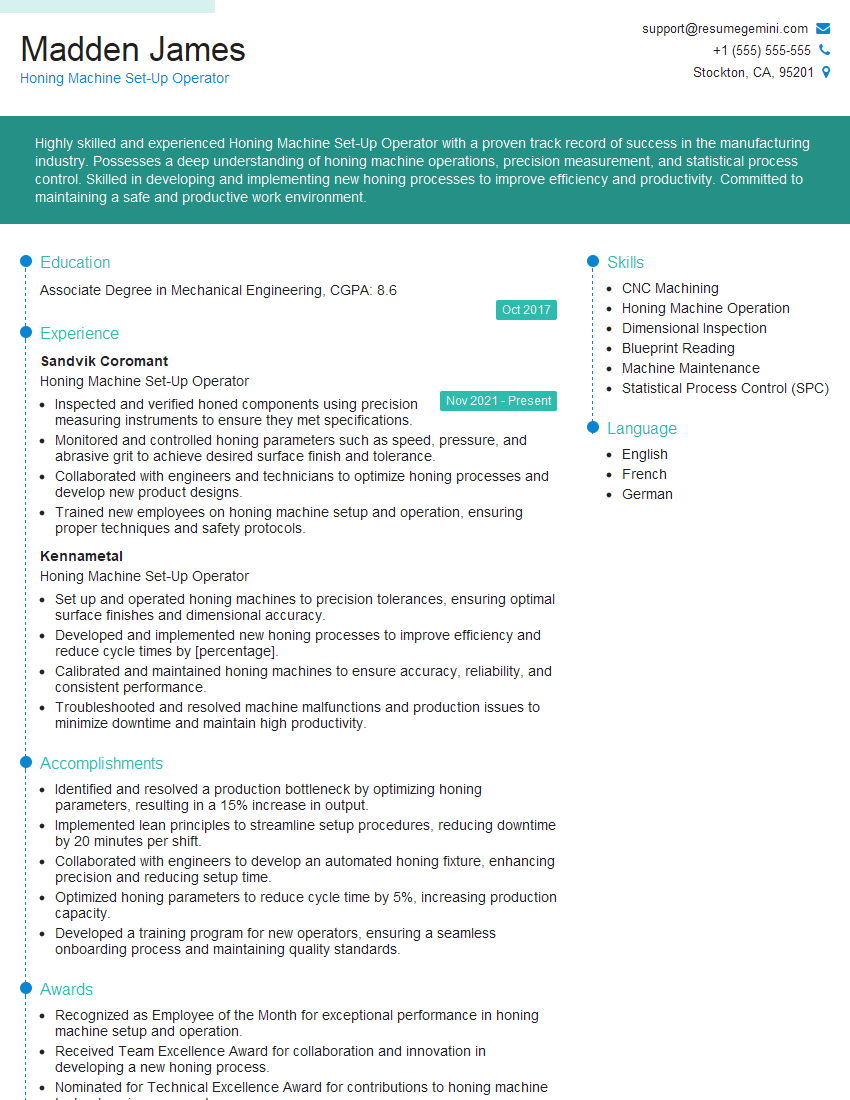

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Honing Machine Set-Up Operator

1. What are the key responsibilities of a Honing Machine Set-Up Operator?

- Setup and operate honing machines to precision-finish the internal surfaces of cylindrical components.

- Interpret engineering drawings and specifications to determine setup parameters.

- Select and install appropriate tooling, abrasives, and coolants.

2. Describe the different types of honing machines and their applications.

Vertical honing machines

- Used for honing cylindrical bores with a vertical orientation.

- Suitable for large and heavy workpieces.

Horizontal honing machines

- Used for honing cylindrical bores with a horizontal orientation.

- Suitable for small and medium-sized workpieces.

3. What are the critical parameters to consider when setting up a honing machine?

- Bore diameter and length

- Material and hardness of the workpiece

- Desired surface finish

- Spindle speed and feed rate

4. How do you ensure the accuracy and consistency of honed parts?

- Regularly calibrate the honing machine

- Use high-quality tooling and abrasives

- Monitor the process parameters during operation

- Perform post-honing inspections to verify dimensions and surface quality

5. What are common troubleshooting techniques for honing machines?

- Check for proper tool engagement

- Adjust spindle speed and feed rate

- Replace worn or damaged tooling

- Calibrate the honing machine if necessary

6. Describe the safety precautions that must be taken when operating a honing machine.

- Wear appropriate personal protective equipment (PPE)

- Ensure the machine is properly grounded

- Keep the work area clean and free of debris

- Follow all lockout/tagout procedures before performing maintenance

7. What is the difference between rough honing and finish honing?

Rough honing

- Involves removing material to achieve the desired bore size and shape.

- Uses coarse abrasives.

Finish honing

- Involves removing any remaining material and improving the surface finish.

- Uses fine abrasives.

8. What are the different types of abrasives used in honing?

- Aluminum oxide

- Silicon carbide

- Diamond

- Cubic boron nitride

9. What are the benefits of using honing as a finishing process?

- High precision and accuracy

- Improved surface finish

- Reduced friction and wear

- Enhanced component performance and durability

10. How do you stay up-to-date on the latest advancements in honing technology?

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Consult with experts in the field

- Participate in continuing education programs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Honing Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Honing Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Honing Machine Set-Up Operator plays a crucial role in ensuring the efficient operation of honing machines within a manufacturing environment. The key job responsibilities of this position include:1. Machine Setup and Operation

- Accurately setting up and calibrating honing machines according to blueprints and specifications.

- Selecting and installing the appropriate honing stones, abrasives, and cutting fluids.

- Monitoring machine operations and adjusting parameters as needed to achieve desired results.

2. Part Inspection and Quality Control

- Inspecting honed components to ensure they meet dimensional tolerances and surface finish requirements.

- Using precision measuring instruments to check critical dimensions and identify any deviations.

- Implementing corrective actions or reporting any issues or defects to supervisors.

3. Machine Maintenance and Troubleshooting

- Performing routine maintenance tasks such as cleaning, lubricating, and adjusting machines.

- Troubleshooting machine malfunctions and repairing minor issues.

- Identifying and reporting more complex problems to maintenance personnel.

4. Process Optimization

- Analyzing machine performance and identifying areas for improvement.

- Conducting experiments to optimize honing parameters, such as abrasive selection and cutting fluid flow rate.

- Collaborating with engineers and supervisors to implement process enhancements.

Interview Tips

To prepare for an interview for a Honing Machine Set-Up Operator position, consider the following tips:1. Research the Industry and Company

- Understand the fundamentals of honing processes and the specific industry where the company operates.

- Research the company’s products, processes, and reputation to demonstrate your interest and knowledge.

2. Highlight Your Technical Skills

- Emphasize your experience in setting up and operating honing machines.

- Describe your proficiency in using precision measuring instruments and performing quality inspections.

- Showcase your troubleshooting and maintenance skills, including your ability to identify and resolve common issues.

3. Demonstrate Your Attention to Detail

- Explain how your meticulous approach to following instructions and maintaining accuracy helps you achieve high-quality results.

- Provide examples of how you ensure that honed components meet or exceed specified tolerances.

4. Show Your Commitment to Improvement

- Discuss your interest in continuous improvement and your eagerness to learn new techniques.

- Explain how you analyze machine performance and implement process enhancements to optimize productivity.

5. Prepare Industry-Specific Questions

- Ask questions related to the company’s specific honing processes, such as the types of materials they process and the desired surface finishes.

- Inquire about the company’s quality control standards and how they ensure customer satisfaction.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Honing Machine Set-Up Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.