Are you gearing up for an interview for a Honing Job Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Honing Job Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

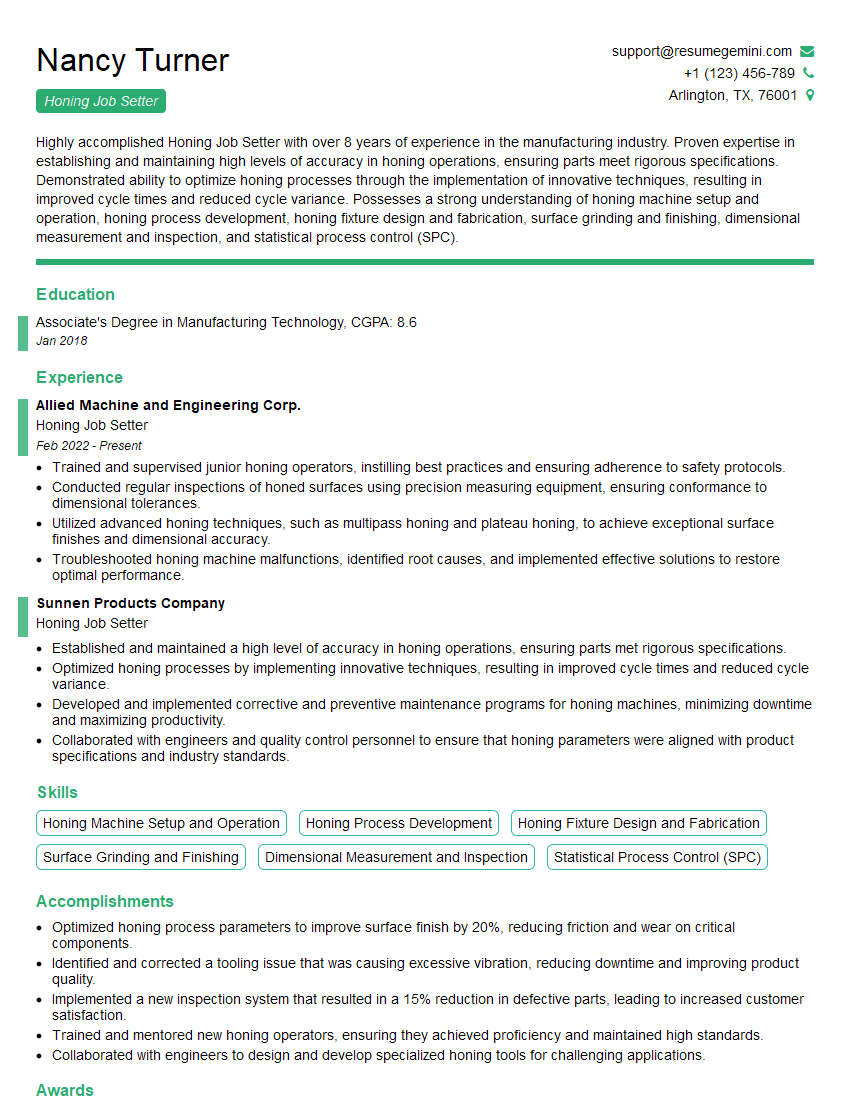

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Honing Job Setter

1. Describe the steps involved in honing a cylinder bore?

As a Honing Job Setter, I am responsible for ensuring the honing process is carried out accurately and efficiently. The steps involved in honing a cylinder bore are:

- Inspect the bore to identify any damage or imperfections.

- Select the appropriate honing tool and grit size based on the desired surface finish and tolerance.

- Set up the honing machine and adjust the parameters, including honing speed, stroke length, and pressure.

- Monitor the honing process and make adjustments as necessary to maintain the desired surface finish and dimensional accuracy.

- Inspect the honed bore to ensure it meets the specifications and is free of any defects.

2. How do you calculate the correct honing speed and pressure for a given material and surface finish?

Factors Affecting Honing Parameters

- Material hardness

- Surface finish requirements

- Honing tool type and grit size

Calculating Honing Speed and Pressure

- Refer to manufacturer’s recommendations and industry standards.

- Use empirical formulas or software to determine optimal parameters.

- Experiment and adjust based on feedback from the honing process.

3. What are the common causes of honing defects and how can they be prevented?

Common honing defects include:

- Taper or out-of-round bore: Caused by uneven pressure distribution or misalignment of the honing tool.

- Chatter marks: Result from excessive vibration during honing.

- Glazing or loading: Occurs when the honing tool becomes dull or clogged, leading to a poor surface finish.

Prevention measures include:

- Ensure proper machine alignment and tool setup.

- Maintain optimal honing parameters and tool condition.

- Use coolants and lubricants to reduce friction and prevent glazing.

4. How do you interpret honing machine readouts and make adjustments to optimize the process?

Honing machine readouts provide valuable information such as:

- Honing pressure: Indicates the force applied to the honing tool against the bore.

- Spindle speed: Controls the rotation of the honing tool.

- Stroke length: Determines the depth of cut during each honing pass.

By analyzing these readouts and comparing them to desired values, I can make adjustments to:

- Improve surface finish and dimensional accuracy.

- Reduce cycle times and increase productivity.

- Prevent defects and ensure consistent results.

5. What is the purpose of diamond honing and when is it used?

Diamond honing is a specialized honing process that utilizes diamond abrasives to achieve extremely fine surface finishes and tight tolerances.

- Purpose: Diamond honing removes minimal material and produces a smooth, mirror-like surface with low friction and high wear resistance.

- Applications: Diamond honing is commonly used in precision industries, such as aerospace, automotive, and medical device manufacturing.

6. How do you maintain and calibrate honing machines to ensure accuracy and precision?

Maintaining and calibrating honing machines is crucial for consistent and high-quality results.

- Regular Inspection and Cleaning: Regularly inspect the machine for wear and tear, and clean all components to remove debris and ensure smooth operation.

- Spindle Calibration: Calibrate the spindle to ensure it runs true and with minimal vibration.

- Pressure Gauge Calibration: Calibrate the pressure gauge to accurately measure the honing pressure applied to the workpiece.

- Dimensional Verification: Perform periodic dimensional checks using precision measuring equipment to ensure the machine is producing parts within tolerance.

7. How do you ensure the safety of operators during honing operations?

Honing operations can involve rotating machinery and sharp tools, so safety is paramount.

- Machine Guarding: Ensure all moving parts, such as belts and pulleys, are properly guarded to prevent contact with operators.

- Personal Protective Equipment (PPE): Provide and enforce the use of appropriate PPE, including safety glasses, earplugs, and gloves.

- Training and Supervision: Train operators on proper machine operation and safety procedures, and provide supervision during initial setup and operation.

8. What troubleshooting techniques do you use when honing machines encounter problems?

Honing machines can occasionally encounter issues that require troubleshooting.

- Vibration or Chatter: Inspect for loose components, misalignment, or worn tools.

- Poor Surface Finish: Check honing tool condition, honing parameters, and coolant flow.

- Dimensional Errors: Verify machine calibration, check for tool wear or workpiece deflection.

- Excessive Cycle Times: Optimize honing parameters, inspect for machine wear or slow spindle speed.

9. How do you stay up-to-date with advancements in honing technology and best practices?

To maintain my skills and knowledge in honing, I actively engage in continuous learning and development.

- Industry Publications and Conferences: Attend industry events, read trade publications, and participate in online forums to stay informed.

- Training and Certification: Undergo training programs offered by machine manufacturers or industry organizations to enhance my technical skills.

- Collaboration and Networking: Connect with other honing professionals, share knowledge, and exchange best practices.

10. How would you improve the efficiency of honing operations in a manufacturing environment?

Improving the efficiency of honing operations requires a holistic approach.

- Process Optimization: Review honing parameters, tool selection, and machine setup to identify areas for improvement.

- Automation and Integration: Explore automation options, such as automatic tool changers or workpiece handling systems, to reduce cycle times.

- Preventive Maintenance: Implement a regular maintenance schedule to minimize downtime and ensure machine reliability.

- Operator Training: Train operators on best practices to increase productivity and prevent errors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Honing Job Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Honing Job Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Honing Job Setters have the crucial responsibility of ensuring the smooth and efficient operation of honing machines. Their primary duties involve setting up, operating, and maintaining these machines to achieve precise and consistent honing results.

1. Machine Setup and Operation

• Installing honing tools and fixtures on the machine

• Setting machine parameters, such as speed, pressure, and stroke

• Loading and unloading workpieces

2. Tool Maintenance

• Monitoring tool wear and replacing tools as necessary

• Dressing and reconditioning honing stones to ensure optimal performance

3. Process Control

• Monitoring and adjusting process variables to maintain workpiece quality

• Inspecting finished workpieces to ensure they meet specifications

• Troubleshooting and resolving production issues

4. Maintenance and Repair

• Performing routine maintenance on honing machines

• Identifying and repairing mechanical or electrical faults

• Keeping a log of maintenance activities and repairs performed

Interview Tips

Preparing for a Honing Job Setter interview requires careful consideration of the key responsibilities and essential skills associated with the role. Here are some tips to help candidates ace the interview:

1. Research the Job and Company

• Thoroughly review the job description and company website to understand the specific requirements and culture of the organization.

• Learn about the company’s products, services, and industry to demonstrate your interest and knowledge.

2. Practice Your Skills

• Brush up on your technical skills, including machine setup, tool maintenance, and process control.

• Practice answering common interview questions related to your skills and experience.

3. Highlight Your Experience

• Quantify your accomplishments using specific examples and metrics to showcase your impact on previous roles.

• Emphasize your ability to maintain high levels of productivity and quality in a fast-paced manufacturing environment.

4. Showcase Your Problem-Solving Abilities

• Describe instances where you successfully identified and resolved production issues or downtime.

• Explain your approach to diagnosing and troubleshooting problems to demonstrate your analytical and critical thinking skills.

5. Prepare Questions for the Interviewer

• Asking thoughtful questions shows your engagement and interest in the role and the company.

• Prepare questions that demonstrate your understanding of the industry, the company’s goals, and the potential for growth within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Honing Job Setter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!