Are you gearing up for an interview for a Jig Grinder Set-Up Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Jig Grinder Set-Up Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

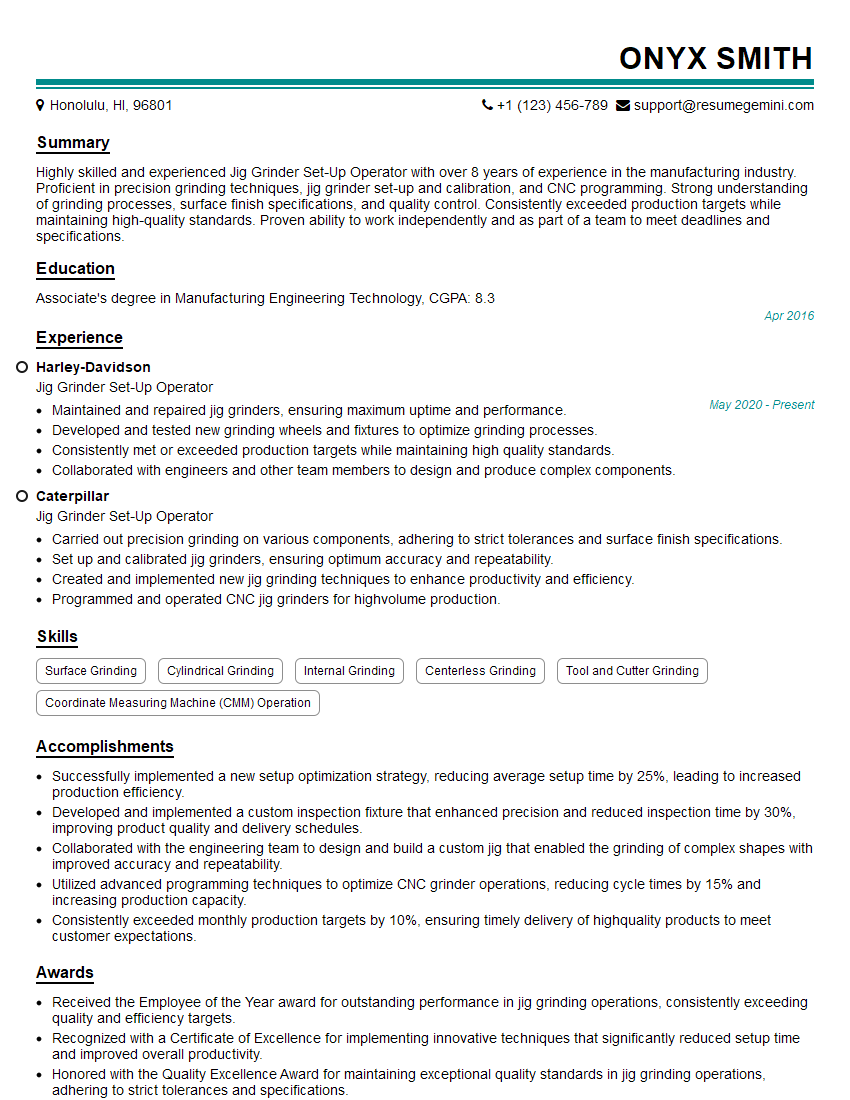

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jig Grinder Set-Up Operator

1. Describe the key responsibilities of a Jig Grinder Set-Up Operator?

- Set up and operate jig grinders to produce precision components according to specifications.

- Inspect and measure workpieces using precision measuring instruments.

- Maintain and calibrate jig grinders and related equipment.

- Troubleshoot and resolve issues with jig grinders and workpieces.

- Follow safety procedures and maintain a clean and organized work area.

2. What types of jigs and fixtures are commonly used in jig grinding?

- Boring jigs

- Milling jigs

- Drilling jigs

- Grinding fixtures

- Inspection fixtures

3. How do you ensure accuracy and precision when setting up and operating jig grinders?

Calibration and Maintenance

- Calibrate jig grinders regularly using certified standards.

- Maintain jig grinders according to manufacturer’s specifications.

Setup Process

- Inspect jigs and fixtures for wear and damage.

- Mount jigs and fixtures securely to the jig grinder.

- Align workpieces precisely using precision measuring instruments.

- Secure workpieces firmly in place to prevent movement during grinding.

4. What techniques do you use to troubleshoot and resolve common issues with jig grinders?

- Identify the symptoms of the issue accurately.

- Check for loose connections, worn parts, or improper settings.

- Refer to manufacturer’s manuals or consult with experienced technicians.

- Use troubleshooting charts or flowcharts to guide the process.

- Document the issue and the steps taken to resolve it.

5. What safety precautions should be taken when operating jig grinders?

- Wear appropriate personal protective equipment (PPE).

- Keep the work area clean and free of tripping hazards.

- Operate jig grinders only when properly trained and authorized.

- Never reach into the grinding area while the machine is running.

- Follow lockout/tagout procedures before performing maintenance or repairs.

6. Describe the different types of grinding wheels used in jig grinding and their applications.

- Extremely hard and durable

- Used for grinding hardened materials such as carbide and ceramics

- Similar to diamond wheels but more cost-effective

- Used for grinding ferrous materials such as steel and cast iron

- Made of various abrasive materials such as aluminum oxide and silicon carbide

- Used for general purpose grinding operations

Diamond Wheels

CBN Wheels

Abrasive Wheels

7. How do you calculate the correct grinding speed and feed rate for a given workpiece?

- Consider the material of the workpiece.

- Refer to manufacturer’s recommendations for grinding wheel speed and feed rate.

- Adjust speed and feed rate based on the desired surface finish.

- Monitor the grinding process and make adjustments as needed.

8. What is the importance of coolant in jig grinding and how do you select the appropriate coolant?

- Coolant reduces friction and heat buildup during grinding.

- Flushes away grinding chips and prevents clogging.

- Enhances surface finish and prolongs tool life.

- Selecting the appropriate coolant depends on the workpiece material and grinding operation.

9. How do you ensure that ground surfaces meet the required specifications and tolerances?

- Use precision measuring instruments to inspect ground surfaces.

- Compare measurements to specifications and identify any deviations.

- Adjust setup parameters or grinding process as necessary to achieve the desired tolerances.

- Document inspection results and make adjustments as needed.

10. Describe your experience in working with different types of materials in jig grinding.

- List the specific materials you have experience working with.

- Explain the challenges and techniques involved in grinding each material.

- Highlight any projects or accomplishments that demonstrate your expertise.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jig Grinder Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jig Grinder Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Jig Grinder Set-Up Operator is a skilled professional who plays a vital role in the precision grinding process. Their primary responsibilities include:

1. Machine Setup and Calibration

Set up and calibrate jig grinders to ensure accurate and efficient operation.

- Install and secure workpieces using various holding devices.

- Adjust machine settings, including grinding wheel speed, feed rate, and depth of cut.

2. Tool Selection and Grinding

Select and grind cutting tools for jig grinders to meet specific requirements.

- Identify and prepare the appropriate grinding wheels based on workpiece material.

- Grind tools to precise dimensions and tolerances using specialized techniques.

3. Production Monitoring and Quality Control

Monitor the grinding process and ensure adherence to quality standards.

- Inspect workpieces using measuring instruments to verify accuracy and dimensions.

- Identify and resolve any deviations or defects during the grinding process.

4. Maintenance and Troubleshooting

Perform routine maintenance and troubleshoot issues with jig grinders.

- Clean and lubricate machines according to manufacturer’s specifications.

- Identify and resolve mechanical or electrical problems that may arise during operation.

Interview Tips

To prepare for an interview for a Jig Grinder Set-Up Operator position, consider the following tips:

1. Research the Company and the Role

Familiarize yourself with the company’s industry, products or services, and the specific requirements of the job.

- Visit the company’s website and social media pages to gather information.

- Review the job description thoroughly to understand the responsibilities and expectations.

2. Highlight Your Technical Skills

Emphasize your proficiency in jig grinding techniques, tool selection, and machine setup and calibration.

- Provide concrete examples of your experience in operating jig grinders and achieving precise results.

- Discuss your understanding of grinding wheel selection and how it affects the finished product.

3. Demonstrate Attention to Detail and Quality

Stress your commitment to quality control and your ability to identify and resolve deviations in the grinding process.

- Describe your experience in inspecting ground workpieces and ensuring adherence to specifications.

- Share examples of how you have implemented quality control measures to improve production efficiency.

4. Emphasize Problem-Solving Abilities

Illustrate your problem-solving skills and your ability to troubleshoot issues with jig grinders.

- Describe real-life situations where you identified and resolved mechanical or electrical problems with jig grinders.

- Explain your systematic approach to diagnosing and solving technical issues.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Jig Grinder Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!