Are you gearing up for an interview for a Job Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Job Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

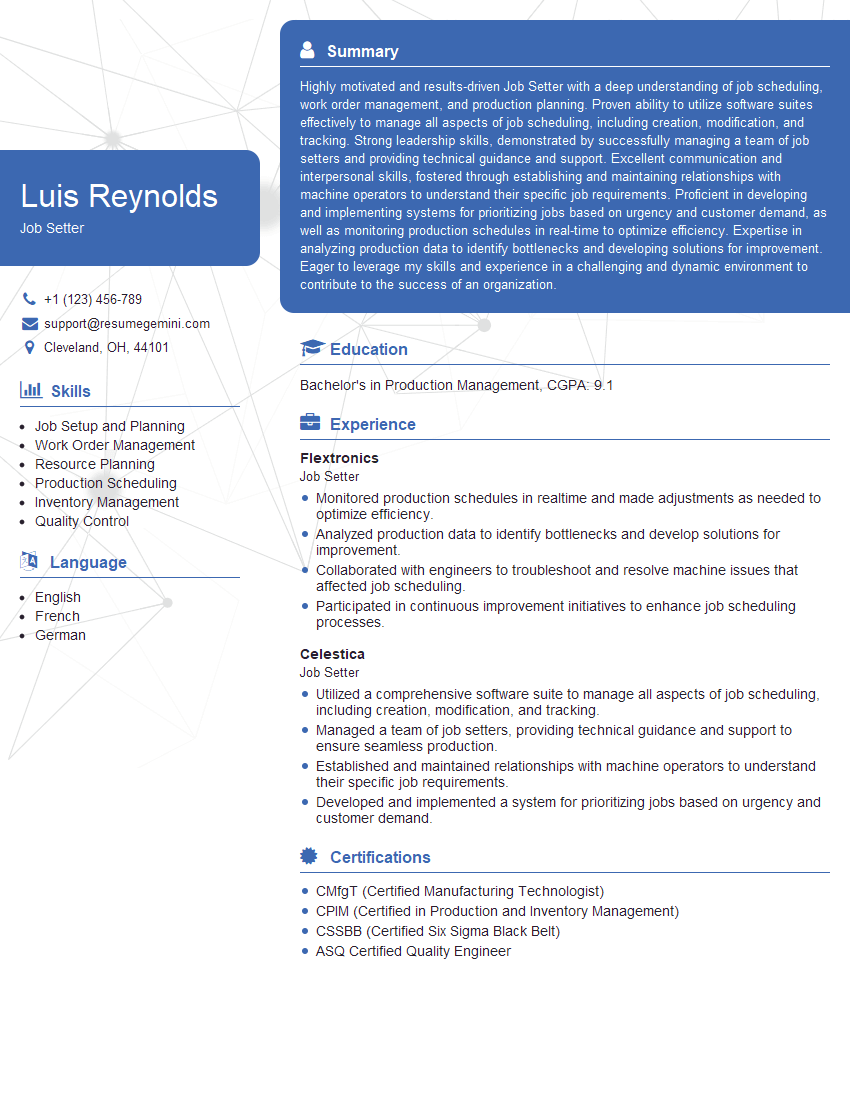

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Job Setter

1. What are your responsibilities as a Job Setter?

As a Job Setter, my primary responsibilities include:

- Preparing and inspecting machines and equipment to ensure they are in correct working condition.

- Determining the appropriate tooling and setup for each job, ensuring accurate and efficient production.

- Setting up and adjusting machines to produce parts or components according to specifications.

- Checking and verifying the quality of finished products and making adjustments as necessary.

- Maintaining a clean and organized work area, ensuring a safe and efficient operation.

- Collaborating with operators and other team members to optimize production processes.

2. Explain the process of setting up a machine for a new job.

Planning and Preparation

- Review work orders and specifications to understand job requirements.

- Gather necessary tools, fixtures, and materials.

Machine Setup

- Install appropriate tooling and fixtures.

- Set machine parameters such as speed, feed rates, and cutting depths.

- Align and position workpieces for accurate processing.

- Conduct test runs and make adjustments as needed.

Verification and Documentation

- Inspect setup and ensure it meets specifications.

- Document setup parameters and any deviations from the standard.

- Train operators on the new setup and safety procedures.

3. How do you ensure the accuracy and precision of your machine setups?

To ensure the accuracy and precision of my machine setups, I follow these key steps:

- Inspect machines regularly to identify and address any potential issues.

- Calibrate machines and equipment using certified measuring instruments.

- Utilize precision tools and gauges to ensure proper measurements and settings.

- Verify setup parameters against work orders and specifications before production begins.

- Conduct test runs and inspect the first few pieces to confirm accuracy and make necessary adjustments.

- Monitor production processes continuously to identify and correct any deviations from specifications.

4. What troubleshooting techniques do you use when equipment malfunctions occur?

When equipment malfunctions occur, I follow a systematic troubleshooting process:

- Identify the symptoms and collect relevant information.

- Refer to technical manuals and consult with experienced colleagues.

- Perform visual inspections and conduct diagnostic tests.

- Isolate the potential cause of the malfunction by testing components and systems.

- Develop and implement appropriate solutions, such as repairing or replacing parts.

- Verify the effectiveness of the repairs and ensure the equipment is operating correctly.

- Document troubleshooting steps and any identified faults for future reference.

5. How do you maintain and optimize production efficiency?

To maintain and optimize production efficiency, I focus on the following strategies:

- Establish clear production schedules and ensure they are followed.

- Identify and eliminate bottlenecks and inefficiencies in the production process.

- Implement lean manufacturing principles, such as 5S and kaizen, to reduce waste and improve flow.

- Regularly assess and upgrade machines and equipment to enhance productivity.

- Train operators on best practices and provide them with ongoing support.

- Monitor production data and identify areas for improvement.

- Collaborate with other departments, such as engineering and maintenance, to optimize overall operations.

6. What software and technological tools are you proficient in for your role as a Job Setter?

I am proficient in various software and technological tools that assist me in my role as a Job Setter:

- Computer-aided design (CAD) and computer-aided manufacturing (CAM) software for machine setup and programming.

- Statistical process control (SPC) tools for monitoring and improving production processes.

- Inventory management systems for tracking materials and ensuring timely supply.

- Predictive maintenance software for scheduling and optimizing maintenance activities.

- Manufacturing execution systems (MES) for real-time production monitoring and data analysis.

7. How do you stay updated with the latest advancements in manufacturing technology?

To stay updated with the latest advancements in manufacturing technology, I engage in the following activities:

- Attend industry conferences and seminars.

- Subscribe to trade publications and technical journals.

- Participate in online forums and discussions.

- Seek training and certification opportunities.

- Network with professionals in the field.

8. How do you prioritize and manage multiple job setups simultaneously?

To prioritize and manage multiple job setups simultaneously, I utilize the following strategies:

- Analyze production schedules and identify critical jobs and deadlines.

- Develop a clear plan and sequence of events for each setup.

- Utilize time management techniques to allocate resources effectively.

- Delegate tasks to team members and provide clear instructions.

- Maintain open communication with operators and supervisors to coordinate efforts.

- Use visual aids, such as Kanban boards, to track progress and identify potential issues.

9. How do you ensure the safety of yourself and others in the work environment?

Ensuring the safety of myself and others in the work environment is a top priority. I adhere to the following practices:

- Follow established safety protocols and wear appropriate personal protective equipment (PPE).

- Inspect machines and work areas regularly to identify potential hazards.

- Receive training on safe operating procedures and emergency response plans.

- Maintain a clean and organized work environment to minimize risks.

- Report any unsafe conditions or incidents promptly.

- Promote a safety-conscious culture and encourage others to prioritize safety.

10. What is your approach to continuous improvement in the workplace?

I believe in the power of continuous improvement and actively pursue opportunities to enhance processes and outcomes in the workplace:

- Identify areas for improvement through regular observation and feedback.

- Collaborate with team members and supervisors to develop and implement solutions.

- Utilize lean manufacturing principles and tools to eliminate waste and optimize processes.

- Monitor and evaluate the effectiveness of improvement initiatives.

- Encourage a culture of innovation and experimentation.

- Celebrate successes and recognize contributions to improvement efforts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Job Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Job Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Job Setters play a pivotal role in the manufacturing industry, ensuring that production processes run smoothly and efficiently.

1. Setting Up and Maintaining Equipment

Job Setters are responsible for setting up and calibrating production equipment, ensuring it operates optimally. They troubleshoot any malfunctions or breakdowns, maintaining equipment uptime and minimizing production delays.

- Install and adjust machinery according to blueprints and specifications

- Calibrate and test equipment to ensure accuracy and efficiency

- Identify and repair mechanical or electrical malfunctions promptly

2. Optimizing Production Processes

Job Setters analyze production processes to identify and eliminate bottlenecks. They implement process improvements and optimize machine settings to maximize productivity while maintaining quality standards.

- Monitor production processes and identify inefficiencies

- Suggest and implement process improvements to reduce cycle times

- Adjust machine parameters to optimize output quality and yield

3. Training and Mentoring Operators

Job Setters are responsible for training and mentoring production line operators. They ensure operators are proficient in machine operation and troubleshoot any issues they encounter.

- Provide on-the-job training to new and existing operators

- Mentor and guide operators to enhance their skills and productivity

- Monitor operator performance and provide feedback for improvement

4. Quality Control and Inspection

Job Setters are responsible for maintaining product quality. They conduct quality inspections and monitor production data to ensure products meet specifications.

- Inspect products for defects and non-conformity

- Analyze production data to identify quality trends and areas for improvement

- Implement quality control measures to prevent defects and ensure product consistency

Interview Tips

Preparing thoroughly for a Job Setter interview is crucial to showcase your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, research the company’s products, services, and industry trends. Demonstrate your knowledge of the industry and understanding of the company’s specific production processes.

2. Highlight Your Technical Skills

Emphasize your expertise in setting up and maintaining production equipment. Quantify your accomplishments by providing specific examples of how you improved productivity or resolved technical issues.

3. Share Your Problem-Solving Abilities

Job Setters are often faced with challenges during production. Discuss your problem-solving approach and provide instances where you successfully identified and resolved production inefficiencies.

4. Demonstrate Your Training and Mentoring Skills

Highlight your ability to train and mentor operators effectively. Discuss your techniques for onboarding new employees and your success in developing operator skills.

5. Emphasize Your Quality Control Experience

Showcase your understanding of quality control principles and your experience in implementing quality measures. Discuss your involvement in defect detection, inspection, and data analysis.

6. Prepare Questions for the Interviewer

Preparing thoughtful questions for the interviewer demonstrates your interest in the company and the role. Ask about the company’s production goals, their plans for process improvement, and their expectations for the Job Setter position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Job Setter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.