Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Jewel Bearing Polisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

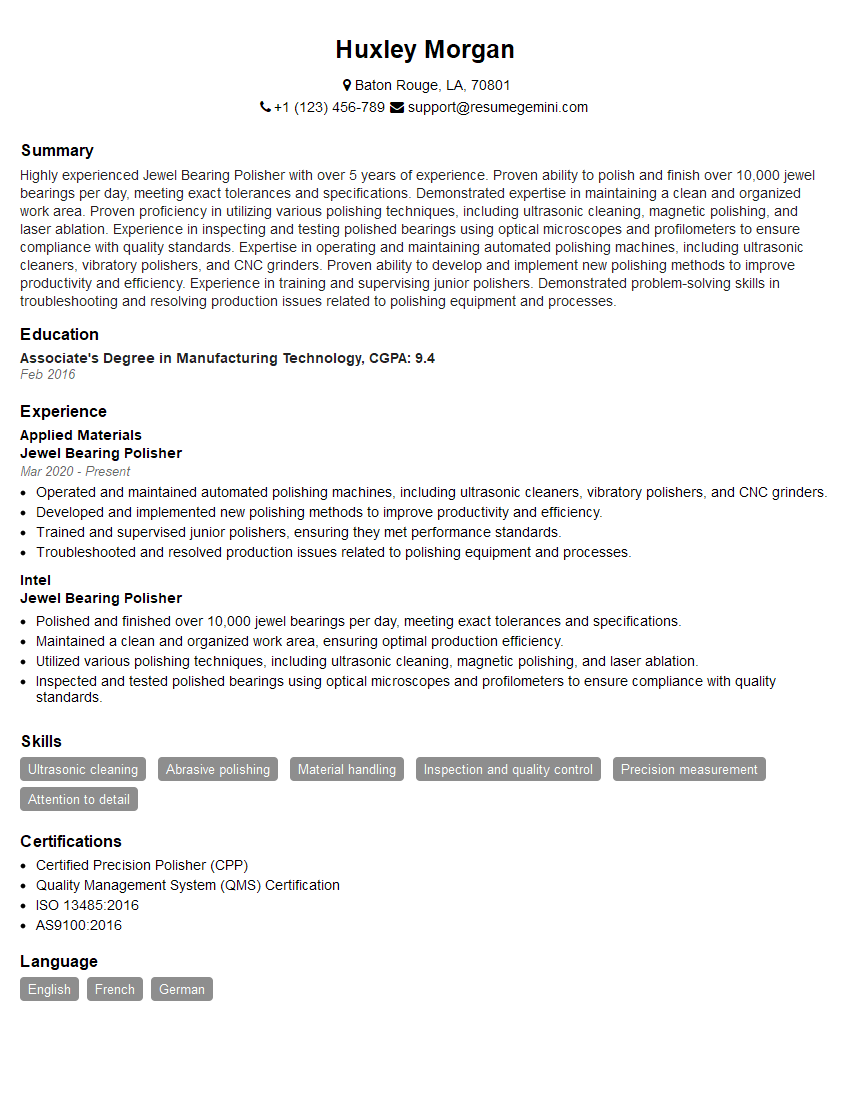

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jewel Bearing Polisher

1. What are the different types of polishing methods used for jewel bearings?

There are several polishing methods used for jewel bearings, including:

- Abrasive polishing: This method uses abrasive particles to remove material from the bearing surface. It is a relatively fast and inexpensive method, but it can produce scratches or other defects on the surface.

- Chemical-mechanical polishing (CMP): This method uses a combination of chemical and mechanical action to remove material from the bearing surface. It is a slower and more expensive method than abrasive polishing, but it produces a smoother and more defect-free surface.

- Electrochemical polishing (ECP): This method uses an electrochemical process to remove material from the bearing surface. It is a relatively slow and expensive method, but it produces a very smooth and defect-free surface.

2. What are the different types of polishing machines used for jewel bearings?

There are several types of polishing machines used for jewel bearings, including:

- Horizontal polishing machines: These machines have a horizontal polishing wheel that rotates against the bearing surface.

- Vertical polishing machines: These machines have a vertical polishing wheel that rotates against the bearing surface.

- Centerless polishing machines: These machines use two polishing wheels that rotate in opposite directions against the bearing surface.

3. What are the different types of polishing tools used for jewel bearings?

There are several types of polishing tools used for jewel bearings, including:

- Abrasive wheels: These wheels are made of abrasive particles, such as diamond or silicon carbide. They are used for abrasive polishing.

- CMP pads: These pads are made of a soft material, such as polyurethane or felt. They are used for CMP.

- ECP electrodes: These electrodes are made of a conductive material, such as copper or graphite. They are used for ECP.

4. What are the different types of polishing fluids used for jewel bearings?

There are several types of polishing fluids used for jewel bearings, including:

- Abrasive slurries: These slurries contain abrasive particles, such as diamond or silicon carbide. They are used for abrasive polishing.

- CMP slurries: These slurries contain chemical agents, such as acids or alkalis. They are used for CMP.

- ECP electrolytes: These electrolytes contain ions, such as copper or chloride. They are used for ECP.

5. What are the different factors that affect the quality of a polished jewel bearing?

The quality of a polished jewel bearing is affected by several factors, including:

- The type of polishing method used

- The type of polishing machine used

- The type of polishing tool used

- The type of polishing fluid used

- The polishing parameters, such as the speed, pressure, and temperature

6. What are the different quality control tests that are performed on polished jewel bearings?

Several quality control tests are performed on polished jewel bearings, including:

- Visual inspection: This test is used to check for defects, such as scratches, chips, or cracks.

- Dimensional measurement: This test is used to check the dimensions of the bearing, such as the diameter, thickness, and surface finish.

- Surface roughness measurement: This test is used to check the smoothness of the bearing surface.

- Hardness test: This test is used to check the hardness of the bearing material.

- Performance test: This test is used to check the performance of the bearing in a real-world application.

7. What are the different applications of polished jewel bearings?

Polished jewel bearings are used in a variety of applications, including:

- Watches and clocks

- Meters and gauges

- Precision instruments

- Medical devices

- Aerospace applications

8. What are the different challenges in polishing jewel bearings?

Polishing jewel bearings presents several challenges, including:

- Producing a smooth, defect-free surface

- Maintaining the accuracy of the bearing dimensions

- Achieving the desired surface roughness

- Polishing a variety of materials, including sapphire, ruby, and diamond

9. How to polish synthetic sapphire jewel bearings while minimizing subsurface damage?

Maintaining the proper slurry environment

- Avoiding the use of high slurry concentration

- Using appropriate lubricants

- Maintaining proper pH levels

Optimizing polishing parameters

- Selecting suitable polishing pressure

- Adjusting polishing speed

- Monitoring temperature

10. What is the role of temperature in the polishing process of jewel bearings?

Temperature plays a crucial role in the polishing process of jewel bearings:

- High temperature can cause the bearing material to soften, which can lead to deformation or damage.

- Low temperature can cause the bearing material to become brittle, which can make it more susceptible to chipping or cracking.

- The optimal temperature for polishing jewel bearings is typically between 20 and 30 degrees Celsius.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jewel Bearing Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jewel Bearing Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Jewel Bearing Polisher is responsible for polishing and finishing jewel bearings, which are used in precision instruments and timepieces. The key responsibilities of the job include:

1. Polishing Jewel Bearings

Jewel bearings are made from synthetic sapphire or ruby and are used to reduce friction in precision instruments and timepieces. Jewel Bearing Polishers use a variety of polishing techniques to achieve the desired surface finish on the bearings.

- Operate polishing machines to remove excess material from jewel bearings

- Use hand tools to polish and finish jewel bearings to meet specifications

- Inspect polished jewel bearings to ensure they meet quality standards

2. Maintaining Equipment

Jewel Bearing Polishers are responsible for maintaining the equipment they use, including polishing machines and hand tools. They must also keep their work area clean and organized.

- Clean and maintain polishing machines and hand tools

- Monitor equipment performance and make adjustments as needed

- Troubleshoot and repair equipment problems

3. Following Safety Procedures

Jewel Bearing Polishers must follow all safety procedures in the workplace. This includes wearing appropriate safety gear and using equipment properly.

- Wear appropriate safety gear, such as gloves, eye protection, and a dust mask

- Follow all safety procedures when operating equipment

- Report any safety hazards to a supervisor

4. Working as Part of a Team

Jewel Bearing Polishers often work as part of a team. They must be able to communicate effectively with other team members and follow instructions.

- Work as part of a team to achieve production goals

- Communicate effectively with other team members

- Follow instructions from supervisors

Interview Tips

Preparing for an interview for a Jewel Bearing Polisher position can be daunting, but there are a few things you can do to increase your chances of success.

1. Know your skills

Make sure you have a clear understanding of the skills and experience required for the position. This will help you to tailor your resume and cover letter to the job and to answer interview questions effectively.

- List your skills and experience in your resume and cover letter

- Be prepared to discuss your skills and experience in detail during the interview

- Provide examples of your work to demonstrate your skills

2. Research the company

Research the company you are applying for. This will help you to understand the company’s culture and values and to prepare for questions about the company’s products or services.

- Visit the company’s website

- Read news articles about the company

- Talk to people who work for the company

3. Practice your answers

Practice answering common interview questions. This will help you to feel more confident and prepared during the interview.

- List common interview questions

- Practice answering the questions out loud

- Get feedback from a friend or family member

4. Dress professionally

Dress professionally for the interview. This will show the interviewer that you are serious about the position and that you respect the company.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Be well-groomed

5. Be on time

Be on time for the interview. This will show the interviewer that you are respectful of their time and that you are serious about the position.

- Plan your route to the interview in advance

- Leave early to allow for unexpected delays

- Call the interviewer if you are running late

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Jewel Bearing Polisher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.