Are you gearing up for an interview for a Knife Glazer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Knife Glazer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

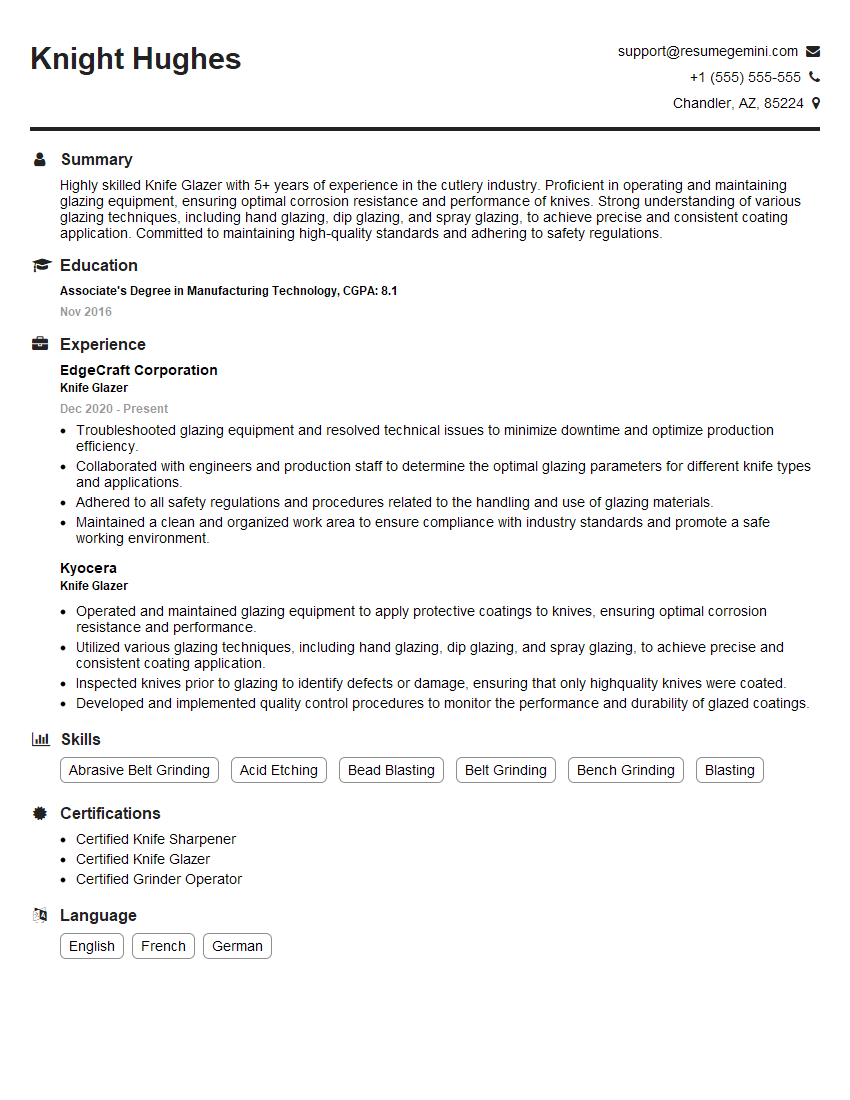

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Knife Glazer

1. What are the safety precautions that you take while operating a glazing machine?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a face shield.

- Inspect the machine before each use to ensure it is in good working order.

- Keep the work area clean and free of debris.

- Follow the manufacturer’s instructions for operating the machine.

- Never attempt to operate the machine if you are tired or under the influence of alcohol or drugs.

2. What are the different types of glazing materials that you are familiar with?

- Diamond glazed: Polishing with diamond compounds, gives a super fine and precise finish.

- Buffed glazed: Polishing with buffing wheels to attain a smooth polished surface.

- Bobbing glazed: Polishing with cloth or leather wheels to attain a high shine.

3. What are the different techniques used for glazing knives?

- Diamond glazing: Using diamond compounds and felt or leather wheels to create a fine, precise finish.

- Buffing: Using buffing wheels and compounds to create a smooth, polished surface.

- Bobbing: Using cloth or leather wheels and compounds to create a high-shine finish.

4. What are the common problems that you encounter while glazing knives and how do you troubleshoot them?

- Problem: The knife is not glazing evenly.

- Solution: Check that the glazing wheel is running true. Adjust the wheel if necessary.

- Problem: The knife is glazing too quickly.

- Solution: Reduce the speed of the glazing wheel.

- Problem: The knife is glazing too slowly.

- Solution: Increase the speed of the glazing wheel.

5. What are the quality control checks that you perform on glazed knives?

- Visual inspection: Inspect the knife for any defects, such as scratches, nicks, or uneven glazing.

- Performance test: Test the knife to ensure that it cuts smoothly and efficiently.

- Durability test: Perform a durability test to ensure that the knife can withstand repeated use.

6. What are the maintenance procedures that you follow for glazing machines?

- Daily maintenance: Clean the machine and inspect it for any damage.

- Weekly maintenance: Lubricate the machine and check the condition of the glazing wheels.

- Monthly maintenance: Perform a thorough inspection of the machine and replace any worn or damaged parts.

7. What are the safety regulations that you are familiar with for glazing knives?

- ANSI B7.1-2014: American National Standard for Safety Requirements for the Use, Care, and Servicing of Abrasive Wheels.

- OSHA 1910.215: Occupational Safety and Health Administration regulations for the use of abrasive wheels.

- ISO 5238-1:2011: International Organization for Standardization regulations for the use of bonded abrasives – Safety requirements – Part 1: General requirements.

8. What are the latest trends in glazing technology?

- Automated glazing machines: These machines can glaze knives automatically, which reduces the risk of injury and improves efficiency.

- Laser glazing: This technology uses a laser to glaze knives, which creates a very precise and durable finish.

- Environmental-friendly glazing: This technology uses environmentally-friendly glazing materials and processes, which reduces the environmental impact of glazing.

9. What are the challenges that you have faced in your previous role as a Knife Glazer?

- Learning to use new glazing equipment: I had to learn how to use a new glazing machine, which was a bit of a challenge at first.

- Meeting production deadlines: I had to learn how to glaze knives quickly and efficiently in order to meet production deadlines.

- Troubleshooting glazing problems: I had to learn how to troubleshoot glazing problems in order to keep the production line running smoothly.

10. What are your career goals?

- Short-term goal: To become a lead knife glazer and train new employees.

- Long-term goal: To start my own knife glazing business.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Knife Glazer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Knife Glazer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Knife Glazers are responsible for applying a protective and decorative coating to knives and other cutting tools. They work in a variety of industries, including manufacturing, construction, and food processing. Key job responsibilities include:

1. Applying coatings

Knife Glazers use a variety of techniques to apply coatings to knives, including brushing, dipping, and spraying. They must be able to apply coatings evenly and smoothly, and they must be able to control the thickness of the coating.

2. Inspecting coatings

Knife Glazers must inspect coatings to ensure that they are free of defects. They must be able to identify and correct any defects that they find.

3. Maintaining equipment

Knife Glazers must maintain the equipment that they use, including brushes, dipping tanks, and spray guns. They must be able to troubleshoot and repair any problems that they encounter.

4. Following safety procedures

Knife Glazers must follow all safety procedures, including wearing protective gear and using proper ventilation. They must be aware of the hazards of the materials that they use and they must take steps to protect themselves from these hazards.

Interview Tips

To prepare for a job interview for a Knife Glazer position, you should:

1. Research the company

Learn as much as you can about the company that you are interviewing with. This will help you to understand the company’s culture and values, and it will also help you to answer questions about the company during the interview.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practicing your answers to these questions will help you to feel more confident and prepared during the interview.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and shoes that are in good condition. You should also avoid wearing strong perfumes or colognes.

4. Be on time

Punctuality is important, so make sure that you arrive for your interview on time. If you are running late, be sure to call the interviewer to let them know.

5. Be yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be yourself and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Knife Glazer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!