Are you gearing up for an interview for a Lapping Machine Set-Up Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lapping Machine Set-Up Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

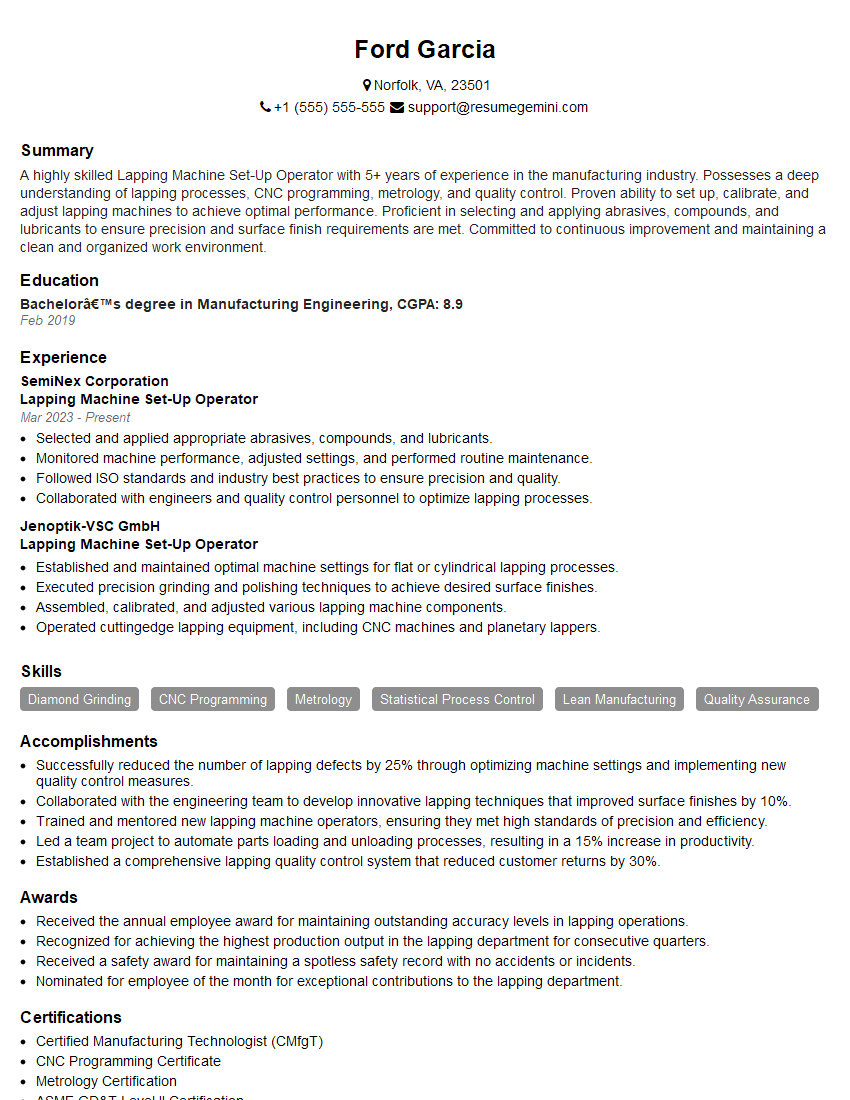

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lapping Machine Set-Up Operator

1. What are the key responsibilities of a Lapping Machine Set-Up Operator?

The Lapping Machine Set-Up Operator is responsible for ensuring that the lapping machine is properly set up and operating correctly. This involves:

- Installing and removing workpieces and fixtures

- Setting up and adjusting the machine’s parameters

- Monitoring the progress of the lapping process

- Making adjustments to the machine as needed

- Maintaining and calibrating the machine

2. What are the different types of abrasives used in lapping?

Polishing Abrasives

- Diamond

- Cubic Boron Nitride (CBN)

- Aluminum Oxide

- Cerium Oxide

Grinding Abrasives

- Silicon Carbide

- Zirconia Alumina

3. What are the three main factors that affect the surface finish of a lapped part?

- Abrasive grit size

- Lapping time

- Lapping pressure

4. What are the safety precautions that must be taken when operating a lapping machine?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat

- Keep the work area clean and free of debris

- Never operate the machine unsupervised

- Do not attempt to make adjustments to the machine while it is running

- Be aware of the potential for flying debris and take appropriate precautions

5. What are the advantages and disadvantages of using a lapping machine?

Advantages

- Can produce very high surface finishes

- Can be used to lap a wide variety of materials

- Relatively low cost

Disadvantages

- Can be time-consuming

- Can be difficult to control the surface finish

- Can generate a lot of waste

6. What are some of the challenges of working as a Lapping Machine Set-Up Operator?

- Maintaining a high level of accuracy and precision

- Working with a variety of materials and processes

- Meeting tight deadlines

- Working in a potentially hazardous environment

7. What are your strengths and weaknesses as a Lapping Machine Set-Up Operator?

My strengths include my ability to:

- Quickly learn and operate new machines

- Work independently and as part of a team

- Maintain a high level of accuracy and precision

- Troubleshoot and solve problems

My weaknesses include my:

- Lack of experience with some types of materials

- Tendency to be perfectionistic

8. What are your salary expectations?

My salary expectations are in line with the industry average for a Lapping Machine Set-Up Operator with my experience and qualifications.

9. What are your career goals?

My career goal is to become a Supervisor in the manufacturing industry.

10. Why are you interested in this position?

I am interested in this position because I am passionate about manufacturing and I am eager to learn more about the lapping process. I am also confident that my skills and experience would make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lapping Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lapping Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lapping Machine Set-Up Operator is responsible for setting up, operating, and maintaining lapping machines used in the manufacturing process. The key job responsibilities include:

1. Machine Setup

Setting up and operating lapping machines according to specifications.

- Interpreting technical drawings and work orders to determine setup requirements.

- Selecting and installing appropriate tooling and abrasives.

- Adjusting machine settings, including speed, feed, and pressure.

2. Machine Operation

Operating lapping machines to achieve desired surface finish and dimensional accuracy.

- Loading and unloading parts from the machine.

- Monitoring machine operation and making necessary adjustments.

- Ensuring that parts are processed within specified tolerances.

3. Machine Maintenance

Performing preventive maintenance and repairs on lapping machines.

- Inspecting and cleaning machines regularly.

- Replacing worn or damaged parts.

- Troubleshooting and resolving machine malfunctions.

4. Quality Control

Inspecting and measuring parts to ensure they meet quality standards.

- Using measuring instruments to check dimensions, surface finish, and other parameters.

- Identifying and correcting non-conforming parts.

- Maintaining records of inspection results.

Interview Tips

Preparing for a job interview as a Lapping Machine Set-Up Operator requires a combination of technical knowledge and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the company and the position

Thoroughly research the company, its products or services, and the specific requirements of the Lapping Machine Set-Up Operator position. This will help you understand the company’s culture, values, and the role you will be playing within the organization.

- Visit the company’s website to learn about their history, mission, and values.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

- Network with professionals in the field to gain insights into the industry and potential job opportunities.

2. Highlight your technical skills and experience

Emphasize your technical skills and experience in operating and maintaining lapping machines. Quantify your accomplishments and provide specific examples of your work.

- Describe your experience in setting up and operating lapping machines, including the types of machines you have worked with.

- Highlight your knowledge of lapping processes, abrasives, and measuring instruments.

- Provide examples of how you have identified and resolved machine malfunctions.

3. Demonstrate your attention to detail and quality control

Lapping Machine Set-Up Operators must have a strong attention to detail and a commitment to quality control. Highlight your ability to inspect and measure parts to ensure they meet specifications.

- Describe your experience in using measuring instruments to check dimensions, surface finish, and other parameters.

- Explain how you identify and correct non-conforming parts.

- Provide examples of how you have maintained records of inspection results.

4. Showcase your problem-solving and communication skills

Lapping Machine Set-Up Operators must be able to solve problems independently and communicate effectively with colleagues and supervisors. Demonstrate your problem-solving skills and provide examples of how you have resolved issues in the past.

- Describe a situation where you identified and resolved a problem with a lapping machine.

- Explain how you communicate with colleagues and supervisors to ensure that parts are processed correctly.

- Provide examples of how you have worked with others to improve processes or solve problems.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lapping Machine Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!