Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Tool Dresser interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Tool Dresser so you can tailor your answers to impress potential employers.

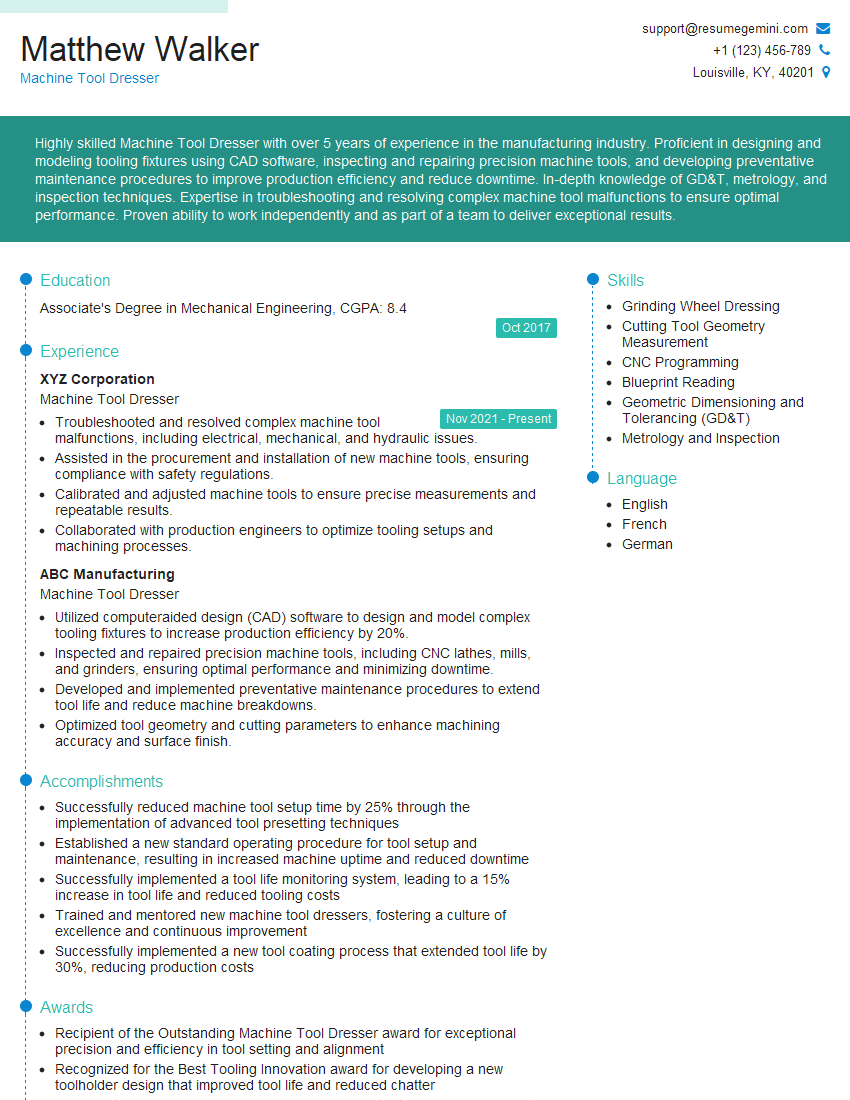

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Tool Dresser

1. Explain the process of setting up and operating a machine tool?

Answer:

- Interpret blueprints and technical drawings to understand the desired part specifications.

- Select and install the appropriate cutting tools, fixtures, and workholding devices.

- Adjust the machine settings, including spindle speed, feed rate, and depth of cut.

- Load the workpiece into the machine and secure it in place.

- Operate the machine safely and efficiently to produce the desired part.

- Monitor the machine during operation to ensure proper functioning and adjust settings as needed.

2. Describe the different types of machine tools and their applications?

Answer:

- Used for turning, boring, threading, and cutting operations on cylindrical workpieces.

- Used for creating complex shapes and profiles by removing material using a rotating cutter.

- Used for creating holes in various sizes and depths.

- Used for finishing and precision processes, such as removing burrs and creating smooth surfaces.

Lathes:

Milling machines:

Drilling machines:

Grinding machines:

3. Discuss the importance of tool selection and maintenance in machine tool operations?

Answer:

- Selecting the right tool ensures optimal cutting performance and extends tool life.

- Properly maintained tools prevent premature wear and breakage, reducing downtime and improving productivity.

- Tool maintenance includes regular sharpening, cleaning, and lubrication to ensure proper functioning.

4. What are the safety precautions that should be taken when operating a machine tool?

Answer:

- Wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Ensure that the machine is properly guarded to prevent access to moving parts.

- Follow established safety protocols and procedures to minimize the risk of accidents.

- Never operate a machine without proper training and authorization.

- Inspect the machine regularly and report any potential hazards to the supervisor.

5. How do you troubleshoot common machine tool problems?

Answer:

- Identify the symptoms of the problem, such as vibration, noise, or improper part production.

- Check for loose or worn components, misaligned parts, or incorrect settings.

- Use diagnostic tools, such as gauges and meters, to identify the root cause of the problem.

- Implement appropriate corrective actions to resolve the issue, such as adjusting settings, replacing parts, or recalibrating the machine.

6. What are the quality control measures involved in machine tool operations?

Answer:

- Inspecting raw materials to ensure they meet specifications.

- Checking part dimensions and tolerances to verify accuracy.

- Performing visual inspections to identify defects or inconsistencies.

- Using measuring instruments and gauges to ensure precision.

- Maintaining quality records and documentation to track performance and identify areas for improvement.

7. How do you maintain and calibrate machine tools?

Answer:

- Performing regular maintenance tasks, such as cleaning, lubrication, and checking fluid levels.

- Inspecting and replacing worn parts as needed.

- Calibrating machines using specialized equipment and procedures to ensure accuracy and precision.

- Following manufacturer’s recommendations for maintenance and calibration schedules.

8. Describe the types of cutting fluids and their applications in machine tool operations?

Answer:

- Water-soluble fluids: Provide cooling, lubrication, and corrosion protection.

- Oil-based fluids: Offer higher lubrication and are suitable for heavy-duty cutting operations.

- Synthetic fluids: Designed for specific applications, such as high-speed machining or exotic materials.

9. What are the different types of CNC controls used in machine tools?

Answer:

- Manual control: Operator manually inputs commands to the machine.

- Computer numerical control (CNC): Computer-controlled system that follows programmed instructions.

- Direct numerical control (DNC): Central computer transmits instructions directly to the machine tool.

10. How do you program and operate a CNC machine tool?

Answer:

- Creating or loading CNC programs using CAM software.

- Verifying and optimizing programs to ensure efficient and accurate machining.

- Operating the CNC machine by inputting programs and monitoring its operation.

- Making adjustments to programs and machine settings as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Tool Dresser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Tool Dresser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

1. Installing and Maintaining Machine Tools

Dressers are responsible for installing and maintaining machine tools, such as lathes, mills, and grinders. This includes assembling, adjusting, and calibrating the machines, as well as performing routine maintenance and repairs.

- Assembling and installing machine tools according to manufacturer’s specifications

- Adjusting and calibrating machine tools to ensure accuracy and precision

- Performing routine maintenance and repairs to keep machine tools running smoothly

2. Preparing and Setting Up Workpieces

In order to produce quality parts, dressers must also prepare and set up workpieces. This includes mounting the workpiece on the machine, aligning it with the cutting tool, and clamping it securely in place.

- Mounting workpieces on the machine according to engineering drawings

- Aligning workpieces with the cutting tool to ensure accuracy

- Clamping workpieces securely in place to prevent movement during machining

3. Monitoring and Operating Machine Tools

Once the machine is set up, dressers monitor and operate it to produce the desired part. This includes starting and stopping the machine, adjusting the cutting speed and feed rate, and monitoring the progress of the operation.

- Starting and stopping the machine tool according to production schedule

- Adjusting the cutting speed and feed rate to optimize machining efficiency

- Monitoring the progress of the machining operation to ensure quality and accuracy

4. Inspecting and Measuring Parts

After the parts are machined, dressers inspect and measure them to ensure that they meet specifications. This includes using precision measuring instruments, such as calipers and micrometers, to check the dimensions and tolerances of the parts.

- Inspecting parts visually for defects or imperfections

- Measuring parts using precision measuring instruments to ensure dimensional accuracy

- Comparing part measurements to specifications to determine conformance

Interview Tips

To ace an interview for a Machine Tool Dresser position, it is important to be well-prepared. Here are some tips to help you prepare:1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you to better understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website to learn about their history, products or services, and mission statement

- Read online reviews and articles about the company to gain insights into its culture and reputation

- Review the job description carefully to identify the key skills and experience required for the position

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver clear and concise responses during the interview.

- Prepare a brief introduction about yourself, highlighting your relevant skills and experience

- Develop a compelling answer to the question “Why are you interested in this position?” that demonstrates your enthusiasm for the job and the company

- Practice answering questions about your strengths and weaknesses, focusing on how your strengths align with the requirements of the position

3. Be Prepared to Discuss Your Experience

The interviewer will want to know about your past experience as a Machine Tool Dresser. Be prepared to discuss your responsibilities, accomplishments, and any challenges you have faced in your previous roles.

- Highlight your experience in installing, maintaining, and operating machine tools

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact

- Be prepared to discuss any challenges you have faced and how you overcame them

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are engaged and interested in the opportunity.

- Ask about the company’s growth plans and future goals

- Inquire about the specific responsibilities and expectations of the position

- Ask about the company’s culture and values to assess if it is a good fit for you

Next Step:

Now that you’re armed with the knowledge of Machine Tool Dresser interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Tool Dresser positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini