Feeling lost in a sea of interview questions? Landed that dream interview for Metal Burnisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metal Burnisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

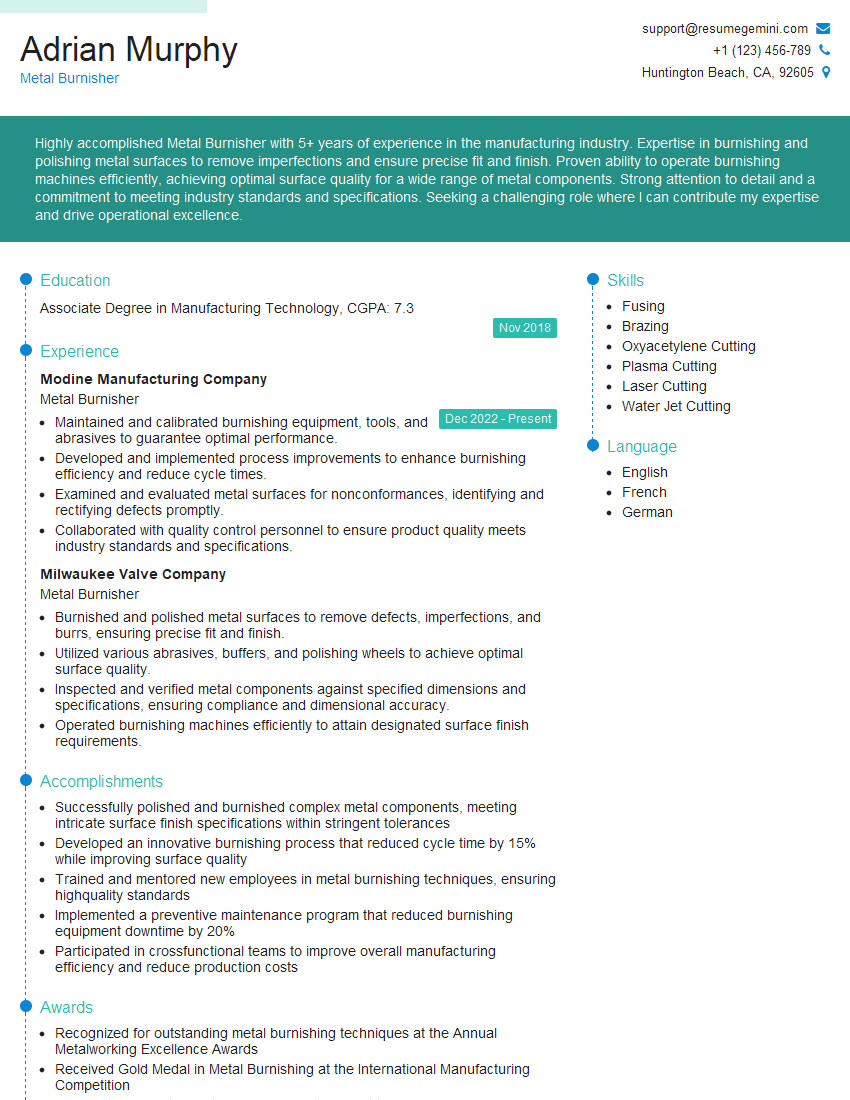

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Burnisher

1. What are the different types of metal burnishing techniques?

- Hand burnishing

- Machine burnishing

- Vibratory burnishing

- Centrifugal burnishing

2. What are the advantages and disadvantages of each technique?

Hand burnishing

- Advantages:

- High precision

- Good surface finish

- No need for special equipment

- Disadvantages:

- Slow process

- Labor-intensive

- Limited to small parts

Machine burnishing

- Advantages:

- Faster than hand burnishing

- Can be automated

- Can handle larger parts

- Disadvantages:

- Not as precise as hand burnishing

- Can be more expensive

- Requires specialized equipment

Vibratory burnishing

- Advantages:

- Gentle process

- Can handle delicate parts

- Can be automated

- Disadvantages:

- Slower than other techniques

- Not as effective on hard metals

- Requires specialized equipment

Centrifugal burnishing

- Advantages:

- Fast process

- Can handle large parts

- Can be automated

- Disadvantages:

- Can be expensive

- Requires specialized equipment

- Not as effective on delicate parts

3. What are the key factors to consider when selecting a burnishing technique?

- The type of metal

- The size and shape of the parts

- The desired surface finish

- The cost of the process

- The availability of equipment

4. What are the common mistakes made by metal burnishers?

- Using the wrong burnishing technique for the job

- Using the wrong tools or equipment

- Not properly preparing the metal surface

- Burnishing for too long or too short a time

- Not properly cleaning the burnished surface

5. What are the safety precautions that must be taken when burnishing metal?

- Wear appropriate safety gear, including gloves, eye protection, and a respirator

- Use the proper tools and equipment for the job

- Follow the manufacturer’s instructions for the burnishing equipment

- Be aware of the potential hazards of the burnishing process, such as flying sparks and sharp edges

- Never leave the burnishing equipment unattended

6. What are the quality control procedures that should be followed when burnishing metal?

- Inspect the metal surface before and after burnishing

- Measure the surface roughness to ensure that it meets the desired specifications

- Check the dimensions of the parts to ensure that they have not been altered by the burnishing process

- Test the parts to ensure that they meet the required performance standards

7. What are the latest trends in metal burnishing technology?

- The use of automated burnishing machines

- The development of new burnishing media

- The use of laser burnishing

- The use of vibratory burnishing for delicate parts

- The use of centrifugal burnishing for large parts

8. What are the challenges facing the metal burnishing industry?

- The rising cost of labor

- The need for faster and more efficient burnishing processes

- The need for more environmentally friendly burnishing processes

- The need for more skilled burnishers

- The competition from other metal finishing processes

9. What are the opportunities for the metal burnishing industry?

- The growing demand for metal burnishing services

- The development of new burnishing technologies

- The increasing use of burnishing for critical applications

- The need for more skilled burnishers

- The opportunity to partner with other metal finishing companies

10. What are your strengths and weaknesses as a metal burnisher?

- Strengths:

- I have over 10 years of experience in metal burnishing.

- I am proficient in all types of burnishing techniques.

- I have a strong understanding of the metallurgy of metals.

- I am a highly skilled craftsman.

- I am a team player and I am always willing to help others.

- Weaknesses:

- I am not always the fastest burnisher.

- I can be a perfectionist at times.

- I am not always good at delegating tasks.

- I am not always the most organized person.

- I am not always the best at communicating with others.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Burnisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Burnisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Burnisher is responsible for improving the aesthetic appeal of metal surfaces by removing burrs, scratches, discoloration, and imperfections. The primary responsibilities of a Metal Burnisher include:

1. Surface Preparation

Preparing metal surfaces for burnishing, including cleaning and degreasing

- Removing rust, scale, and other impurities

- Ensuring surfaces are smooth and free of defects

2. Burnishing

Applying burnishing tools and techniques to smooth and polish metal surfaces

- Using abrasive brushes, wheels, or polishing compounds

- Achieving desired surface finish and luster

3. Quality Control

Inspecting finished surfaces to ensure they meet specifications

- Checking for defects, scratches, or uneven finishes

- Ensuring adherence to quality standards

4. Maintenance and Equipment Operation

Maintaining and operating burnishing equipment

- Cleaning, lubricating, and adjusting machinery

- Ensuring equipment is in good working condition

Interview Tips

To ace an interview for a Metal Burnisher position, candidates should consider the following tips:

1. Research the Industry

Familiarize yourself with the metalworking industry, common burnishing techniques, and industry-specific terminology.

- Read industry publications and articles

- Attend industry events and conferences

2. Highlight Relevant Skills

Emphasize your proficiency in metalworking, surface preparation, and burnishing techniques. Provide specific examples of your experience and accomplishments.

- Use keywords from the job description in your resume and interview responses

- Quantify your experience whenever possible

3. Demonstrate Attention to Detail

Metal Burnishers must have a keen eye for detail and precision. In the interview, highlight your ability to perform meticulous work and ensure high-quality finishes.

- Provide examples of projects where you demonstrated attention to detail

- Explain how you maintain quality standards in your work

4. Showcase Technical Knowledge

Interviewers will assess your technical knowledge of burnishing equipment and processes. Prepare to discuss different types of abrasives, polishing compounds, and surface preparation methods.

- Research common burnishing tools and their applications

- Understand the principles of metal finishing and polishing

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Burnisher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.