Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Burrer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

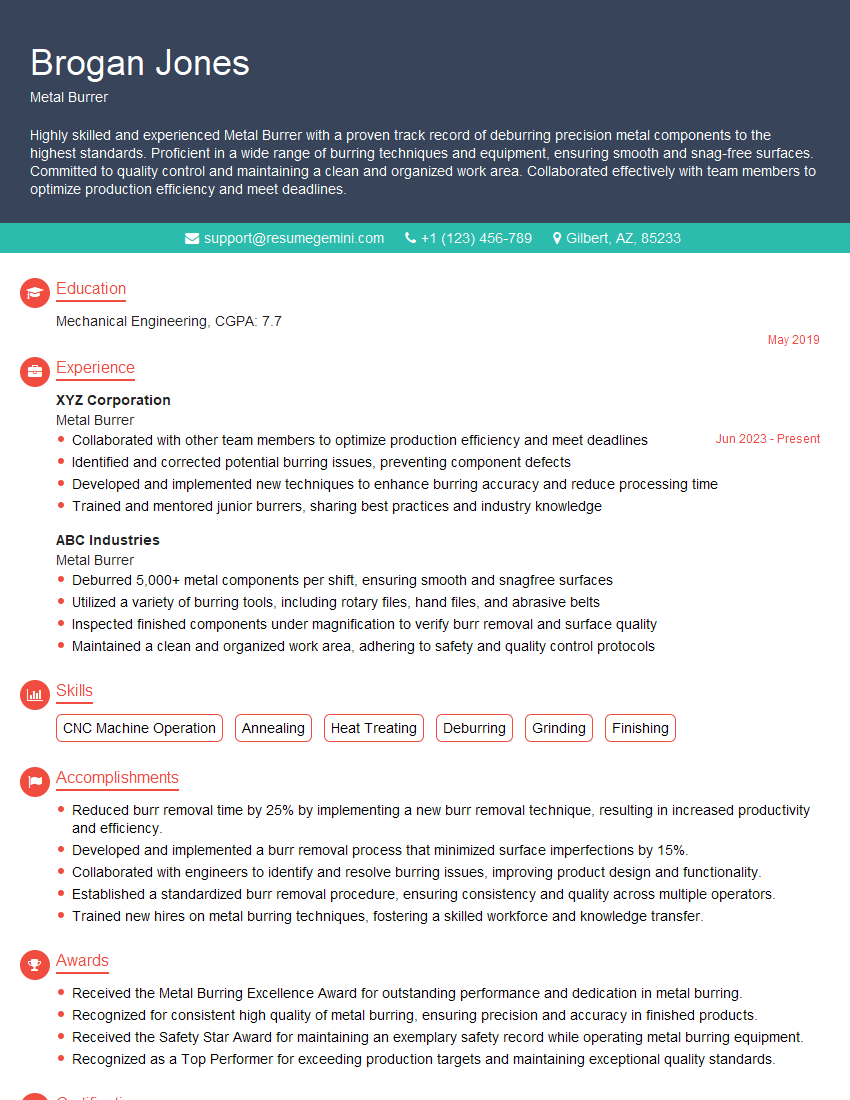

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Burrer

1. How do you determine the correct burr speed for different materials and burr sizes?

To determine the correct burr speed for different materials and burr sizes, I consider several factors:

- Material Hardness: Harder materials require slower burr speeds to prevent burning or excessive wear. Softer materials can handle higher speeds.

- Burr Size: Smaller burrs require higher speeds to achieve the same surface finish as larger burrs. Larger burrs can operate at lower speeds.

- Burr Type: Different burr types, such as rotary burrs and end mills, have optimal speed ranges based on their geometry.

- Desired Surface Finish: A finer surface finish requires slower burr speeds, while a rougher finish can be achieved at higher speeds.

2. What are the key safety considerations when operating a metal burring machine?

Proper Equipment:

- Wear appropriate safety gear, including eye, ear, and respiratory protection.

- Ensure the burring machine is properly guarded and maintained.

Work Environment:

- Maintain a clean and organized work area to prevent tripping hazards.

- Provide adequate ventilation to remove dust and fumes generated by burring.

Machine Operation:

- Securely clamp the workpiece to prevent movement.

- Never operate the machine with loose clothing, jewelry, or long hair that could get caught.

- Avoid overextending the burr tool, as this can cause breakage and injury.

3. How do you inspect burrs for wear and damage?

I perform regular inspections of burrs to ensure they are sharp and free of damage:

- Visual Inspection: Examine the burr teeth for signs of wear, chipping, or breakage.

- Micrometer Measurement: Measure the diameter of the burr teeth to determine if they have worn down significantly.

- Test Cut: Perform a small test cut on a scrap piece of material to assess the burr’s cutting ability and surface finish.

4. What techniques do you use to achieve specific surface finishes on metal surfaces?

To achieve specific surface finishes, I employ various burring techniques:

- Rotary Burring: Using a rotary burr tool, I control the speed, pressure, and angle of contact to create smooth, polished surfaces.

- Hand Deburring: With a scraper or file, I manually remove burrs and sharp edges from intricate parts or areas that are difficult to reach with a machine.

- Electrochemical Deburring: I utilize an electrolytic process that dissolves small burrs and creates smooth, rounded edges on conductive materials.

- Barrel Deburring: I place parts in a rotating barrel filled with abrasive media to remove burrs and achieve a uniform surface finish.

5. How do you handle and store burring tools properly?

I prioritize proper handling and storage of burring tools to maintain their longevity and safety:

- Handling: I store burrs in designated tool holders or boxes to prevent damage.

- Cleaning: I clean burrs thoroughly after use to remove metal chips and debris.

- Sharpening: I have the necessary equipment and knowledge to sharpen burrs when necessary.

- Lubrication: I apply lubricants to burrs to minimize friction and extend their lifespan.

6. What is your experience with using different types of burring machines?

I have extensive experience operating various burring machines, including:

- Pneumatic Die Grinders: Handheld machines that provide high-speed rotation for burring and finishing.

- Benchtop Burring Machines: Stationary machines with a fixed burr and adjustable worktable for precise burring.

- Barrel Deburring Machines: Machines that utilize a rotating barrel with abrasive media to deburr large quantities of parts.

- Electrochemical Deburring Machines: Machines that use an electrolytic process to dissolve burrs on conductive materials.

7. How do you establish and maintain quality standards for metal burring operations?

I implement the following measures to ensure quality and consistency in metal burring operations:

- Visual Inspection: I visually inspect parts after burring to ensure burr removal and surface finish meet specifications.

- Dimensional Inspection: I use measuring instruments such as calipers and micrometers to verify part dimensions and tolerances.

- Surface Roughness Testing: I utilize surface roughness gauges to measure and document the smoothness of finished surfaces.

- Process Documentation: I maintain detailed records of burring parameters, tool settings, and inspection results.

8. How do you work effectively in a team environment when performing metal burring operations?

In a team environment, I prioritize collaboration and communication:

- Task Coordination: I communicate with teammates to divide tasks and coordinate work schedules.

- Knowledge Sharing: I exchange ideas and techniques with colleagues to improve processes.

- Quality Control: I actively participate in quality checks and provide feedback to maintain standards.

- Safety Awareness: I ensure my actions align with team safety protocols and alert others to potential hazards.

9. What are your strengths and weaknesses as a Metal Burrer?

Strengths:

- Precision and Attention to Detail: I take pride in producing high-quality burred surfaces that meet specifications.

- Technical Proficiency: I have a strong understanding of burring techniques and can adapt to various materials and requirements.

- Efficiency and Productivity: I optimize my workflow and utilize appropriate tools to maximize output.

Weaknesses:

- Limited Experience with Large-Scale Projects: My experience primarily focuses on small to medium-sized burring operations.

- Physical Demands: Prolonged burring operations can be physically demanding, and I am still building my endurance.

10. Do you have any questions for me about the Metal Burrer position or the company?

I am eager to learn more about the following:

- The company’s quality standards for metal burring

- The typical volume and variety of burring projects handled by your team

- Opportunities for professional development and training in metal burring techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Burrer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Burrer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Burrers play a crucial role in the manufacturing process by removing burrs and sharp edges from metal parts, ensuring their smooth functioning and safety.

1. Deburring and Finishing Metal Parts

Using various tools and techniques, Metal Burrers remove burrs and sharp edges from metal parts, such as castings, stampings, and machined components.

2. Maintaining and Inspecting Equipment

They maintain and inspect deburring equipment, such as grinders, buffers, and hand tools, to ensure optimal performance and safety.

3. Quality Control

Metal Burrers inspect deburred parts to ensure they meet quality standards, checking for surface finish, dimensional accuracy, and absence of defects.

4. Safety and Compliance

They adhere to safety regulations and wear appropriate protective gear to minimize risks while working with metal parts and deburring equipment.

Interview Tips

Preparing for an interview as a Metal Burrer requires a combination of technical knowledge and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Gain insights into the company’s operations, the industry they serve, and any specific requirements for Metal Burrers in their organization.

2. Highlight Your Deburring Skills

Emphasize your experience and proficiency in deburring techniques, using specific examples and quantifying your accomplishments whenever possible.

3. Demonstrate Equipment Knowledge

Show that you are familiar with different types of deburring equipment and have a good understanding of their operation and maintenance.

4. Showcase Your Quality Assurance Mindset

Explain how you ensure the quality of your work by inspecting parts for burrs, sharp edges, and other defects.

5. Prepare Safety-Related Questions

Ask questions about the company’s safety procedures and how you can contribute to maintaining a safe work environment.

6. Practice Your Communication Skills

Be clear and concise in your answers, and demonstrate your ability to communicate effectively with both supervisors and colleagues.

7. Dress Professionally and Arrive Prepared

Create a good first impression by dressing appropriately and arriving at the interview on time with all necessary documents.

8. Be Enthusiastic and Show Interest

Convey your passion for metalworking and your eagerness to contribute to the company. Enthusiasm can often set you apart from other candidates.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal Burrer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.