Are you gearing up for an interview for a Notch Grinder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Notch Grinder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

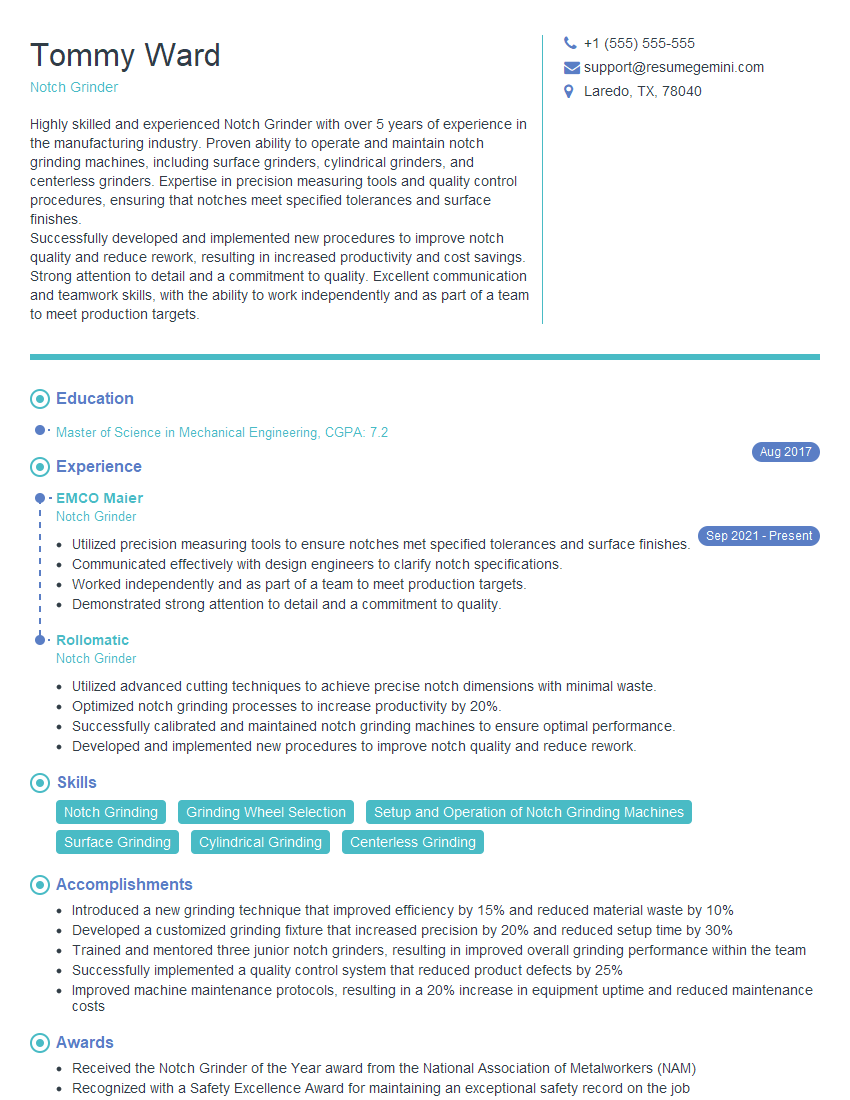

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Notch Grinder

1. Explain the process of setting up and calibrating a CNC notch grinder?

The process of setting up and calibrating a CNC notch grinder involves several steps:

- Mounting the workpiece: The workpiece is securely mounted on the grinding table using a fixture or chuck.

- Setting the grinding wheel: The grinding wheel is mounted on the spindle and positioned correctly in relation to the workpiece.

- Calibrating the axes: The CNC control system is used to calibrate the X, Y, and Z axes to ensure accurate positioning.

- Setting the grinding parameters: The grinding speed, feed rate, and depth of cut are programmed into the CNC control.

- Testing the setup: A test cut is performed to verify the accuracy and efficiency of the setup.

2. What are the different types of grinding wheels used in notch grinding?

Abrasive materials

- CBN (Cubic Boron Nitride): High hardness and wear resistance, suitable for grinding hard materials.

- Diamond: Extremely high hardness, used for grinding very hard materials like carbide.

Bond types

- Vitrified: Ceramic bond, provides good grinding performance and durability.

- Resin: Synthetic bond, offers high grinding efficiency and reduced heat generation.

- Metal: Metal bond, provides high strength and excellent surface finish.

Grain size and shape

- Grain size: Smaller grains produce finer finishes, while larger grains remove more material.

- Grain shape: Different grain shapes, such as blocky or conical, affect the grinding action.

3. How do you select the appropriate grinding wheel for a specific application?

Selecting the appropriate grinding wheel involves considering several factors:

- Material of the workpiece: Different materials require specific abrasive materials and bond types.

- Desired surface finish: The grain size and shape of the grinding wheel influence the surface roughness.

- Grinding operation: The type of grinding (e.g., roughing, finishing, profiling) determines the grinding wheel specifications.

- Machine capabilities: The grinding wheel must be compatible with the spindle speed and power of the machine.

- Cost and availability: The cost and availability of the grinding wheel should also be considered.

4. What are the safety precautions that must be taken when operating a notch grinder?

- Wear appropriate PPE: Safety glasses, gloves, hearing protection, and a dust mask.

- Secure workpiece: Ensure the workpiece is securely mounted to prevent accidents.

- Inspect the machine: Check the grinder for any defects or damage before operation.

- Use proper guards: Always use the provided guards and shields to protect from flying sparks and debris.

- Avoid contact with moving parts: Keep hands and clothing away from rotating wheels and other moving parts.

- Maintain the machine: Regularly clean and lubricate the grinder to ensure optimal performance and safety.

- Never leave the machine unattended: Stop the grinder and disconnect power when not in use.

5. Explain the different techniques used to grind notches in various materials?

Hardened steels

- CBN grinding: Using CBN grinding wheels due to their high hardness and wear resistance.

- EDM (Electrical Discharge Machining): A non-contact process that uses electrical sparks to remove material.

Soft materials

- Burr grinding: Using a burr grinding wheel to remove material from the edges of a hole.

- Peripheral grinding: Using a cylindrical grinding wheel to grind the notch.

Thin materials

- Laser cutting: Using a laser to precisely cut the notch.

- Waterjet cutting: Using a high-pressure waterjet to cut the notch.

6. How do you determine the optimal grinding parameters for a notch grinding operation?

Determining the optimal grinding parameters involves considering several factors:

- Material of the workpiece: Different materials require different grinding speeds and feed rates.

- Desired surface finish: Finer finishes require lower grinding speeds and feed rates.

- Machine capabilities: The grinding machine’s spindle speed and power limit the grinding parameters.

- Cooling and lubrication: Using coolant or lubrication can improve grinding efficiency and reduce heat generation.

- Cost and production time: A balance between grinding efficiency and cost must be considered.

7. Explain the different types of coolants used in notch grinding and their advantages?

Water-soluble coolants

- Advantages: Inexpensive, readily available, provides cooling and lubrication.

Oil-based coolants

- Advantages: Superior lubrication, protects against corrosion, extends tool life.

Synthetic coolants

- Advantages: Can be tailored to specific applications, environmentally friendly, long-lasting.

8. What are the common troubleshooting techniques for notch grinding issues?

Chatter

- Reduce grinding speed or feed rate.

- Increase wheel sharpness or use a different abrasive.

- Balance the workpiece properly.

Burning

- Reduce grinding pressure or feed rate.

- Increase coolant flow.

- Use a finer grain grinding wheel.

Poor surface finish

- Use a finer grain grinding wheel.

- Reduce grinding speed or feed rate.

- Check for wheel wear or damage.

9. Describe the maintenance procedures for a notch grinder to ensure its optimal performance?

- Regular cleaning: Remove dust, debris, and coolant buildup from the machine.

- Lubrication: Lubricate moving parts as per manufacturer’s recommendations.

- Wheel dressing: Dress the grinding wheel regularly to maintain its shape and sharpness.

- Coolant system maintenance: Flush and clean the coolant tank and pump.

- Safety inspection: Conduct regular safety inspections to ensure proper operation and prevent accidents.

- Follow manufacturer’s guidelines: Refer to the manufacturer’s manual for specific maintenance instructions.

10. How do you stay updated with the latest developments and best practices in notch grinding?

- Industry publications: Read trade magazines and journals related to grinding technology.

- Conferences and exhibitions: Attend industry events to learn about new products and techniques.

- Online resources: Utilize online forums, technical articles, and manufacturer websites for information.

- Training and certification: Participate in training programs and obtain certifications to enhance skills.

- Networking: Connect with other notch grinding professionals to exchange knowledge and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Notch Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Notch Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Notch Grinder is a skilled professional responsible for operating notch grinding machines to create accurate and precise notches in various materials. The key responsibilities of a Notch Grinder include:

1. Notch Grinding

Operate notch grinding machines to grind precise notches into metal, plastic, or other materials.

- Select and install appropriate grinding wheels and fixtures.

- Adjust machine settings to achieve desired notch dimensions and tolerances.

2. Quality Control

Inspect and measure ground notches to ensure they meet specifications.

- Use precision measuring tools, such as micrometers and calipers, to verify dimensions.

- Identify and correct defects or deviations from specifications.

3. Machine Maintenance

Perform routine maintenance on notch grinding machines to ensure optimal performance.

- Lubricate and clean machine components.

- Identify and replace worn or damaged parts.

4. Work Environment

Work in a manufacturing or production environment with potential exposure to noise, dust, and machinery.

- Follow safety protocols and wear appropriate personal protective equipment.

- Maintain a clean and organized work area.

Interview Tips

To ace an interview for a Notch Grinder position, it is essential to prepare thoroughly by researching the company, the role, and industry trends. Here are some interview tips and hacks to help you stand out:

1. Research the Company and Position

- Visit the company’s website to learn about their business, products, and culture.

- Read industry publications and news articles to stay informed about the latest trends in notch grinding.

2. Highlight Relevant Skills and Experience

- Emphasize your proficiency in operating notch grinding machines and your ability to achieve precise results.

- Showcase your understanding of quality control procedures and your commitment to producing high-quality work.

3. Demonstrate Problem-Solving Abilities

- Prepare examples of how you have successfully resolved technical problems or improved efficiency in previous roles.

- Be prepared to discuss your approach to troubleshooting and finding solutions independently.

4. Practice Confidence and Enthusiasm

- Practice your answers to common interview questions and prepare questions to ask the interviewer.

- Project confidence and enthusiasm throughout the interview to convey your interest in the role and the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Notch Grinder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Notch Grinder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.