Are you gearing up for a career in Polisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Polisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

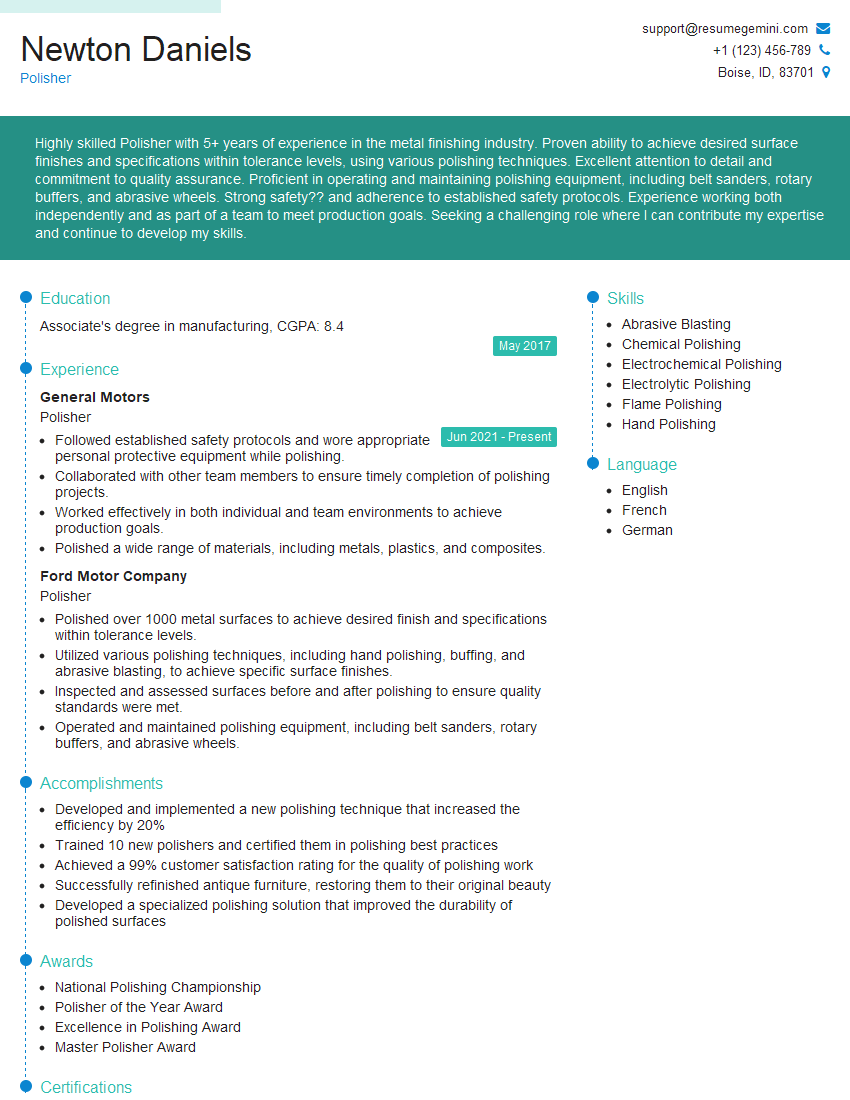

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Polisher

1. What are the different types of polishing machines and their respective uses?

There are various types of polishing machines, each with its own specific purpose. Here are some common types:

- Rotary polishers: These machines use a rotating pad to polish surfaces. They are commonly used for polishing cars, boats, and other large surfaces.

- Orbital polishers: Orbital polishers use a combination of rotation and oscillation to polish surfaces. They are less aggressive than rotary polishers and are ideal for polishing delicate surfaces, such as painted surfaces or fiberglass.

- Random orbital polishers: These machines use a random orbital motion to polish surfaces. They are less likely to leave swirls or holograms in the finish than rotary or orbital polishers.

- Dual-action polishers: Dual-action polishers combine the features of rotary and orbital polishers. They offer a balance of power and precision, making them suitable for a wide range of polishing tasks.

2. How do you determine the correct polishing compound and pad combination for a specific material?

Factors to consider:

- Material type: Different materials have different hardness and porosity levels, which require different polishing compounds and pads.

- Desired finish: The desired finish, whether it be a high-gloss finish or a matte finish, will determine the type of polishing compound and pad used.

- Machine type: The type of polishing machine being used can also influence the choice of polishing compound and pad.

General guidelines:

- For hard materials, such as metal or glass, a coarse polishing compound and a firm pad should be used.

- For soft materials, such as paint or plastic, a fine polishing compound and a soft pad should be used.

- For a high-gloss finish, a finishing polish and a soft pad should be used.

- For a matte finish, a compound polish and a firm pad should be used.

3. How do you prevent swirls and holograms when polishing surfaces?

- Use a clean polishing pad: Dirty or contaminated pads can cause scratches and swirls in the surface.

- Apply the polishing compound evenly: Uneven application of the polishing compound can lead to swirls and holograms.

- Use the correct polishing technique: Different materials require different polishing techniques. Use the recommended technique for the material you are polishing.

- Avoid overheating the surface: Overheating the surface can damage the material and cause swirls and holograms.

- Use a finishing polish: A finishing polish can help to remove any remaining swirls or holograms from the surface.

4. What are the safety precautions that should be taken when polishing?

- Wear appropriate safety gear: This includes safety glasses, gloves, and a dust mask.

- Use the polishing machine in a well-ventilated area: Polishing can generate dust and fumes that can be harmful if inhaled.

- Be aware of the electrical cords: Keep the electrical cords away from the polishing machine and the work area.

- Do not touch the polishing pad while it is running: The polishing pad can be hot and can cause burns.

- Allow the polishing machine to cool down before storing it: This will help to prevent the machine from overheating and causing a fire.

5. How do you maintain a polishing machine?

- Clean the polishing pad regularly: Dirty or contaminated pads can cause scratches and swirls in the surface.

- Inspect the polishing machine regularly: Check the machine for any loose parts or damage.

- Lubricate the polishing machine regularly: This will help to keep the machine running smoothly.

- Store the polishing machine in a dry place: Moisture can damage the machine.

6. Can you describe the steps involved in polishing a metal surface?

Steps:

- Clean the surface: Remove any dirt or debris from the surface.

- Apply polishing compound: Apply a small amount of polishing compound to the polishing pad.

- Polish the surface: Use the polishing machine to polish the surface. Start with a low speed and gradually increase the speed as needed.

- Wipe off the polishing compound: Use a clean cloth to wipe off the polishing compound from the surface.

- Inspect the surface: Inspect the surface for any scratches or swirls. If necessary, repeat the polishing process.

7. What are the different types of abrasives used in polishing?

- Natural abrasives: These abrasives occur naturally, such as pumice and tripoli.

- Synthetic abrasives: These abrasives are man-made, such as aluminum oxide and silicon carbide.

- Diamond abrasives: These abrasives are made from diamond particles and are the hardest and most durable abrasives available.

8. How do you choose the correct abrasive for a specific polishing job?

- Consider the material being polished: Different materials require different abrasives.

- Consider the desired finish: The desired finish, whether it be a high-gloss finish or a matte finish, will determine the type of abrasive used.

- Consider the polishing machine being used: Different polishing machines use different types of abrasives.

9. What is the difference between a cutting compound and a finishing compound?

- Cutting compound: A cutting compound is a coarse abrasive that is used to remove scratches and other imperfections from a surface.

- Finishing compound: A finishing compound is a fine abrasive that is used to produce a high-gloss finish on a surface.

10. How do you troubleshoot a polishing machine that is not working properly?

- Check the power: Make sure that the polishing machine is plugged in and that the power switch is turned on.

- Check the brushes: The brushes may be worn out and need to be replaced.

- Check the bearings: The bearings may be worn out and need to be replaced.

- Check the motor: The motor may be burned out and need to be replaced.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Polishers are responsible for the final step in the production process and play a crucial role in ensuring the quality and aesthetics of the finished product. Their key job responsibilities include:

1. Polishing and Buffing

Using specialized tools and equipment, polishers smooth and polish surfaces of various materials such as metals, plastics, and wood. They ensure that the surface achieves the desired level of shine, texture, and smoothness.

- Operate polishing and buffing machines to remove imperfections and enhance surface finish.

- Select and apply appropriate abrasives, compounds, and polishes to achieve specific surface effects.

2. Inspection and Quality Control

Polishers are responsible for inspecting and evaluating the quality of polished surfaces. They identify and correct any defects or imperfections to ensure that the finished product meets the required standards.

- Inspect polished surfaces to ensure they meet specifications for smoothness, shine, and texture.

- Identify and correct any imperfections or defects using appropriate tools and techniques.

3. Preparation and Cleaning

Prior to polishing, polishers prepare the surface by cleaning and removing any contaminants or debris. They also prepare the tools and equipment required for the polishing process.

- Clean and prepare surfaces prior to polishing to ensure proper adhesion of abrasives and polishes.

- Set up and maintain polishing machines, ensuring they are in good working order.

4. Material Handling

Polishers handle a variety of materials, including metals, plastics, and wood. They move and position these materials safely and efficiently throughout the polishing process.

- Handle and transport materials to and from polishing stations.

- Ensure proper storage and handling of abrasives, compounds, and polishes.

Interview Tips

To ace a Polisher interview, it is important to highlight your skills, experience, and attention to detail. Consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry reputation. Research the specific polishing techniques and materials relevant to the position you are applying for.

2. Practice Your Answers

Prepare concise and specific answers to common interview questions. Practice describing your experience in polishing, highlighting your ability to achieve high-quality results.

3. Emphasize Attention to Detail

Polishers must have a keen eye for detail and accuracy. Highlight your ability to identify and correct imperfections, ensuring that the finished product meets the required standards.

4. Showcase Your Technical Skills

Demonstrate your proficiency in using polishing machines, abrasives, and compounds. Explain how you select and apply these materials to achieve specific surface effects.

5. Highlight Safety and Work Habits

Polishers must adhere to safety protocols and maintain a clean and organized work area. Emphasize your commitment to safety and your ability to work independently and as part of a team.

6. Ask Informed Questions

Show your interest and engagement by asking thoughtful questions about the company, the position, and the polishing process. This demonstrates your eagerness to learn and your commitment to the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Polisher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.