Feeling lost in a sea of interview questions? Landed that dream interview for Polisher Apprentice but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Polisher Apprentice interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

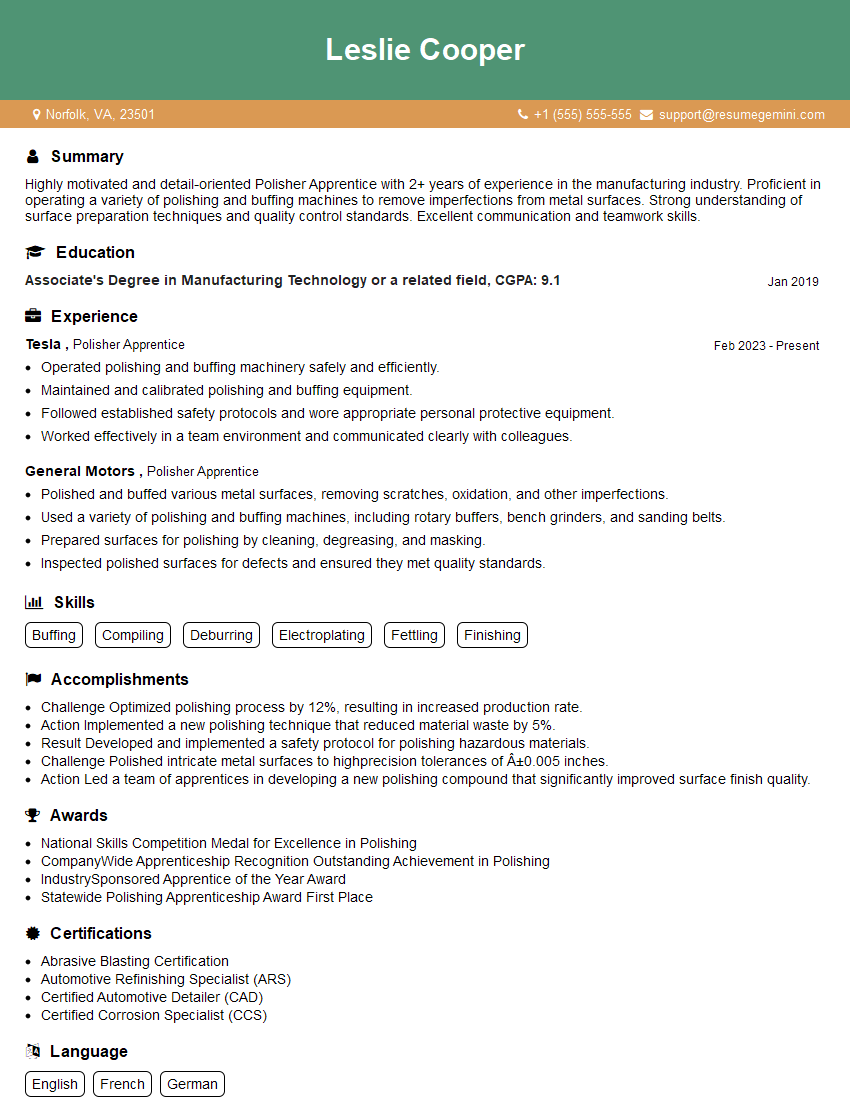

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Polisher Apprentice

1. What is the difference between wet and dry polishing?

- Wet polishing uses water or a lubricant to cool and reduce friction, resulting in a finer finish.

- Dry polishing does not use any liquid, creating more heat and a rougher finish.

2. What are the different types of polishing pads used for metal surfaces?

Abrasive pads

- Used for removing scratches and imperfections.

- Graded by grit size, with lower grits being more aggressive.

Buffing pads

- Used to smooth and polish surfaces after abrasive pads.

- Typically made of foam, wool, or microfiber.

3. What are some common mistakes to avoid when polishing metal surfaces?

- Applying too much pressure, which can damage the surface.

- Using the wrong type of pad or polish for the surface.

- Not cleaning the surface properly before polishing.

- Polishing in an uncontrolled environment, such as dusty areas.

4. What are the safety precautions that should be taken when using a polishing machine?

- Always wear eye protection, gloves, and a respirator.

- Secure the workpiece properly to prevent movement.

- Keep the machine clean and well-maintained.

- Follow the manufacturer’s instructions for safe operation.

5. How do you determine the correct speed and pressure to use for polishing a particular metal surface?

- Consider the type of metal, its hardness, and the desired finish.

- Start with a low speed and pressure and gradually increase until the desired results are achieved.

- Use a test area to experiment with different settings before applying to the entire surface.

6. What types of polishes are used for different metal surfaces?

- Aluminum polish for aluminum surfaces.

- Chrome polish for chrome surfaces.

- Stainless steel polish for stainless steel surfaces.

- Brass polish for brass surfaces.

7. How do you handle delicate metal surfaces when polishing?

- Use a soft polishing pad and apply light pressure.

- Move the polisher in small, circular motions.

- Avoid rubbing too hard or using abrasive pads.

8. What is the importance of surface preparation before polishing?

- Removes dirt, oil, and other contaminants that can interfere with polishing.

- Creates a smooth surface for better adhesion of polish.

- Enhances the final polished result.

9. How do you maintain and store polishing equipment?

- Clean polishing pads regularly with water or a solvent.

- Lubricate moving parts of the polishing machine.

- Store equipment in a dry, dust-free environment.

10. Describe a challenging polishing task you have encountered and how you overcame it.

(Candidate’s own experience and answer may vary)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Polisher Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Polisher Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Polisher Apprentices assist experienced polishers in the preparation and polishing of metal, plastic, or wood surfaces to achieve a desired finish.

1. Surface Preparation

Prepare surfaces for polishing by cleaning, sanding, or buffing to remove dirt, rust, or other imperfections.

- Use various tools and techniques to clean and smooth surfaces.

- Inspect surfaces to ensure they are ready for polishing.

2. Polishing

Operate polishing machines to apply abrasive compounds or polishes to surfaces.

- Select appropriate polishing compounds and techniques based on the material and desired finish.

- Monitor the polishing process to ensure the desired results are achieved.

3. Finishing

Inspect polished surfaces to ensure they meet specifications.

- Apply protective coatings or sealants to finished surfaces.

- Clean and maintain polishing equipment.

4. Safety and Quality

Follow safety protocols to ensure a safe work environment.

- Wear personal protective equipment (PPE) such as gloves, eye protection, and respirators.

- Maintain a clean and organized work area.

- Adhere to quality standards and specifications.

Interview Tips

To ace the interview for a Polisher Apprentice position, follow these tips:

1. Research the Company and Role

Visit the company website and learn about their industry, products, and culture. Research the specific role you are applying for and its responsibilities.

- Show the interviewer that you are interested in the company and position.

- Tailor your answers to demonstrate how your skills align with the job requirements.

2. Practice Your Answers

Prepare for common interview questions related to your skills, experience, and motivation. Practice your answers out loud to enhance your delivery and confidence.

- Be prepared to discuss your previous experience in surface preparation, polishing, and finishing.

- Emphasize your attention to detail, safety awareness, and willingness to learn.

3. Highlight Relevant Skills

In your resume and interview, highlight your skills in surface preparation, operating polishing machines, and quality control. Mention any certifications or training you have received.

- Quantify your accomplishments whenever possible, using numbers or metrics.

- Provide specific examples of how you have used your skills to achieve positive results.

4. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to show your interest and engagement. This demonstrates that you are eager to learn more about the company and the role.

- Ask about the company’s apprenticeship program and opportunities for advancement.

- Inquire about the work environment and safety protocols.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Polisher Apprentice interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.