Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Balance Wheel Facer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

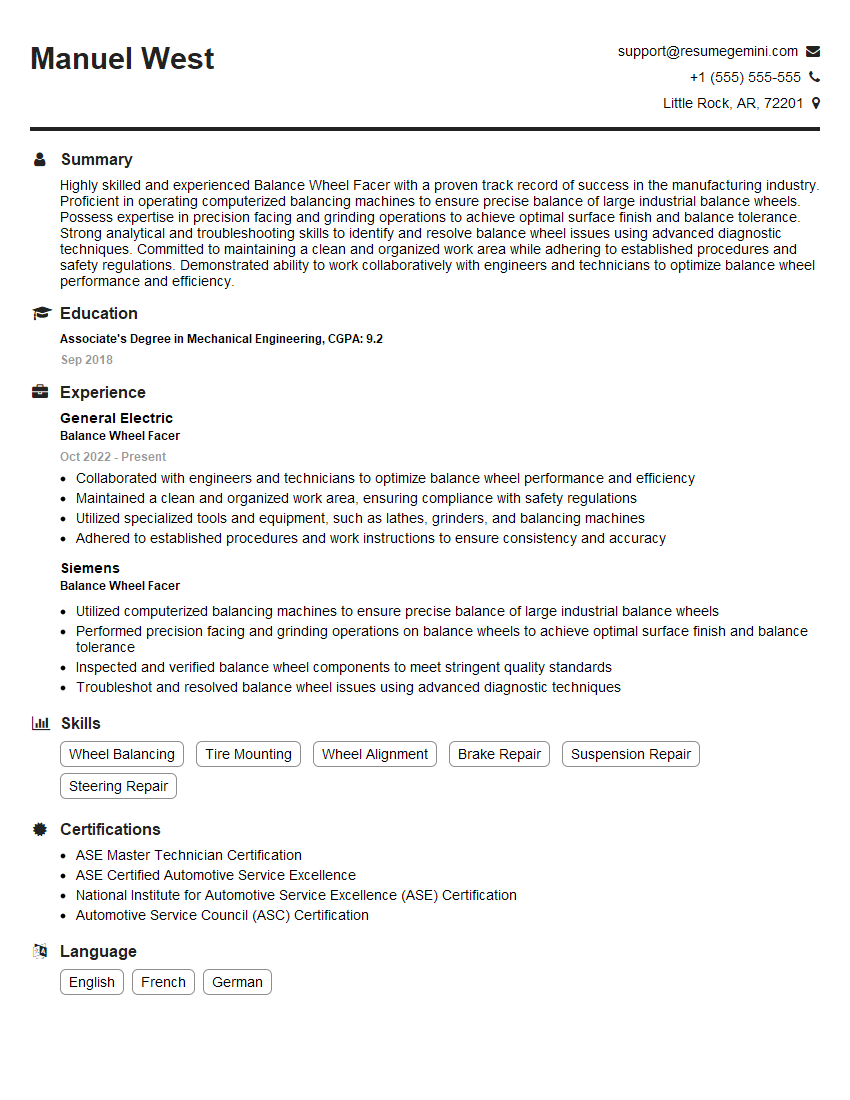

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Balance Wheel Facer

1. What are the different types of balance wheel facers and their applications?

Balance wheel facers are used to resurface the faces of balance wheels and are available in a variety of types to suit different applications. Some of the most common types include:

- Vertical balance wheel facers are designed to be used on a vertical axis and are typically used for larger balance wheels.

- Horizontal balance wheel facers are designed to be used on a horizontal axis and are typically used for smaller balance wheels.

- Manual balance wheel facers are operated by hand and are typically used for small-scale applications.

- CNC balance wheel facers are computer-controlled and are typically used for high-volume applications.

2. What are the safety procedures that need to be followed when using a balance wheel facer?

Proper training

- Make sure the balance wheel facer is properly secured and stable before use.

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

Proper operation

- Be aware of the location of the cutting tool and keep your hands away from it.

- Do not operate the balance wheel facer if it is damaged or malfunctioning.

- Never leave the balance wheel facer unattended while it is running.

Proper storage

- When finished using the balance wheel facer, turn it off and allow it to cool down completely before storing it.

- Store the balance wheel facer in a dry, well-ventilated area.

3. What are the different types of cutting tools that can be used on a balance wheel facer?

The type of cutting tool that can be used on a balance wheel facer will depend on the type of balance wheel facer and the material being cut. Some of the most common types of cutting tools include:

- Diamond grinding wheels are used for grinding hard materials such as steel and carbide.

- CBN grinding wheels are used for grinding soft materials such as aluminum and brass.

- Inserted blade cutters are used for cutting a variety of materials, including wood, plastic, and metal.

- PCD (polycrystalline diamond) inserts are used for cutting hard materials such as steel and carbide.

4. How do you determine the correct cutting speed and feed rate for a balance wheel facer?

The correct cutting speed and feed rate for a balance wheel facer will depend on the type of cutting tool being used, the material being cut, and the desired surface finish. As a general rule, the following guidelines can be used:

- For diamond grinding wheels, the cutting speed should be between 1,000 and 2,000 surface feet per minute (SFM) and the feed rate should be between 0.001 and 0.003 inches per revolution (IPR).

- For CBN grinding wheels, the cutting speed should be between 500 and 1,000 SFM and the feed rate should be between 0.0005 and 0.002 IPR.

- For inserted blade cutters, the cutting speed should be between 500 and 1,000 SFM and the feed rate should be between 0.001 and 0.005 IPR.

- For PCD inserts, the cutting speed should be between 1,000 and 2,000 SFM and the feed rate should be between 0.0005 and 0.002 IPR.

5. How do you measure the surface finish of a balance wheel after it has been faced?

The surface finish of a balance wheel can be measured using a variety of methods, including:

- Visual inspection can be used to identify major defects such as scratches, gouges, and cracks.

- Profilometry can be used to measure the surface roughness of a balance wheel.

- Laser scanning can be used to create a 3D model of a balance wheel’s surface.

6. What are the different types of balancing machines that can be used to balance balance wheels?

There are a variety of balancing machines that can be used to balance balance wheels, including:

- Static balancing machines are used to balance balance wheels that are not rotating.

- Dynamic balancing machines are used to balance balance wheels that are rotating.

- Vibration analyzers are used to measure the vibration of balance wheels and can be used to identify imbalances.

7. How do you determine the correct balancing weight for a balance wheel?

The correct balancing weight for a balance wheel can be determined using a variety of methods, including:

- The trial and error method involves adding and removing weights until the balance wheel is balanced.

- The mathematical method involves using a mathematical formula to calculate the correct balancing weight.

- The graphical method involves using a graph to determine the correct balancing weight.

8. What are the different types of balancing standards that can be used to balance balance wheels?

There are a variety of balancing standards that can be used to balance balance wheels, including:

- ISO 1940 is an international standard that specifies the requirements for balancing balance wheels.

- ANSI S2.19 is an American national standard that specifies the requirements for balancing balance wheels.

- DIN 6888 is a German national standard that specifies the requirements for balancing balance wheels.

9. What are the different types of balancing fluids that can be used to balance balance wheels?

There are a variety of balancing fluids that can be used to balance balance wheels, including:

- Water is the most common balancing fluid and is typically used for small balance wheels.

- Oil is a thicker balancing fluid that is typically used for larger balance wheels.

- Glycerol is a viscous balancing fluid that is typically used for high-speed balance wheels.

10. What are the different types of balancing machines that can be used to balance balance wheels?

There are a variety of balancing machines that can be used to balance balance wheels, including:

- Horizontal balancing machines are used to balance balance wheels that are mounted on a horizontal axis.

- Vertical balancing machines are used to balance balance wheels that are mounted on a vertical axis.

- Combination balancing machines can be used to balance balance wheels that are mounted on either a horizontal or vertical axis.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Balance Wheel Facer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Balance Wheel Facer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Balance Wheel Facer is responsible for operating and maintaining machines that shape and smooth metal wheel blanks to prepare them for the production of watch components. Their primary duties encompass:

1. Machine Operation

Operate computer-controlled machines to cut, form, and finish raw wheel blanks based on drawings and specifications

- Load and position blanks in the machine

- Monitor machines and adjust settings to ensure optimal operation

2. Quality Control

Inspect finished wheels to ensure they meet dimensional, finish, and tolerance specifications

- Use measuring tools and gauges to verify accuracy

- Identify and correct any defects or deviations

3. Tool Maintenance

Maintain and troubleshoot machine tools, including cutting heads and fixtures

- Inspect and sharpen cutting tools

- Adjust and calibrate machines for optimal performance

4. Production Optimization

Analyze production processes to identify areas for improvement

- Collaborate with engineers to optimize machine settings

- Implement process improvements to increase efficiency and reduce waste

Interview Tips

To ace an interview for a Balance Wheel Facer position, candidates should:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and market position. Understanding the industry trends will demonstrate your interest and enthusiasm.

- Visit the company website and read about their mission, values, and products

- Research industry publications and news to stay informed about current developments

2. Highlight Relevant Experience and Skills

Emphasize your experience in precision machining, quality control, and tool maintenance. Quantify your accomplishments whenever possible to demonstrate your impact.

- Provide specific examples of your involvement in wheel facing operations or related processes

- Discuss your understanding of quality standards and your ability to troubleshoot machine problems

3. Demonstrate Problem-Solving Abilities

Interviewers will be interested in your ability to analyze problems and develop solutions. Share examples from your previous experience where you identified and resolved manufacturing issues.

- Describe a time when you optimized a process or improved machine efficiency

- Explain how you troubleshoot and resolve quality deviations

4. Be Prepared to Discuss Industry Knowledge

Interviewers may ask questions about industry trends or new technologies. Show that you are knowledgeable about the field and enthusiastic about staying up-to-date.

- Discuss your understanding of the latest advancements in watchmaking technology

- Share your thoughts on how industry advancements could impact the role of Balance Wheel Facers

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Balance Wheel Facer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.