Are you gearing up for an interview for a Bolt Threader position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bolt Threader and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

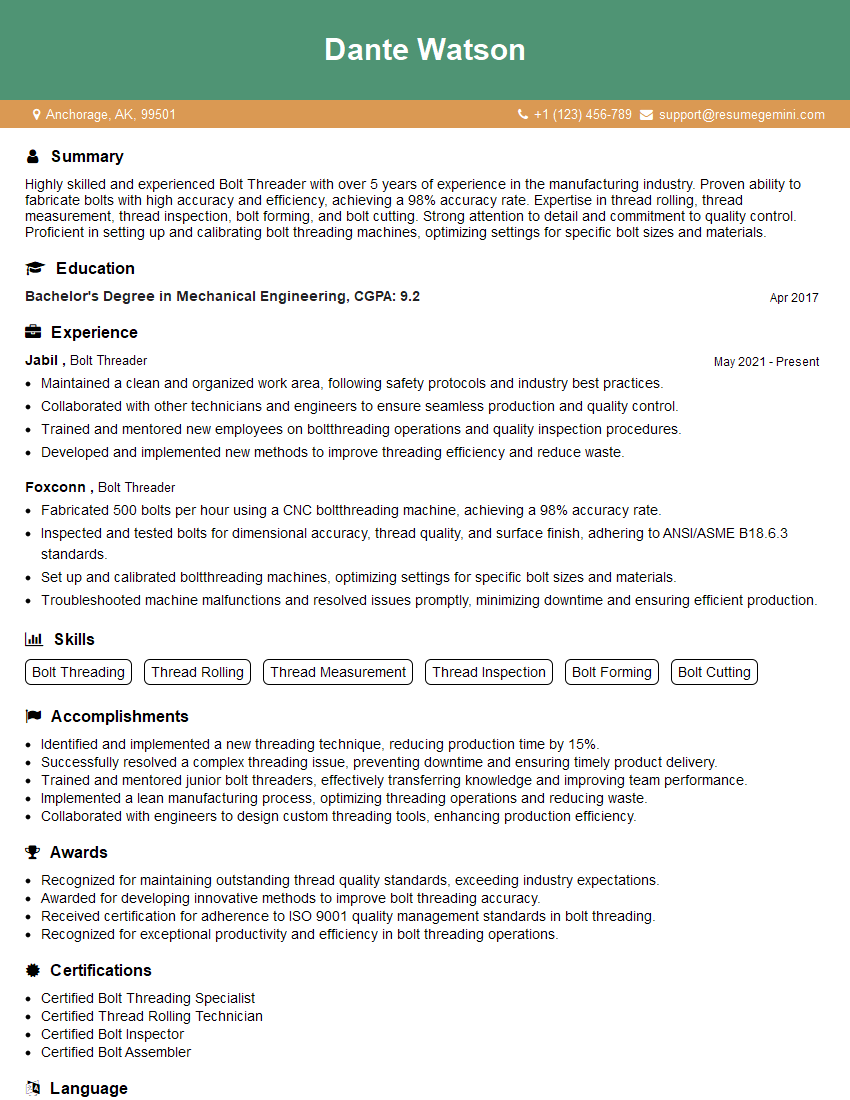

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bolt Threader

1. How do you determine the correct tap drill size for a given bolt size?

- Identify the thread standard (e.g., UNC, UNF, metric) and pitch for the bolt.

- Consult a tap drill size chart or use a formula to calculate the drill diameter based on the thread pitch.

- For example, for a 1/4-20 UNC bolt, the tap drill size is 13/64 inch.

- Consider factors such as material hardness and hole tolerance when selecting the drill size.

2. Describe the process of tapping a hole.

Centering:

Align the tap with the center of the hole using a tap handle or tapping machine.Starting the thread:

Apply slight downward pressure and rotate the tap clockwise to cut the first few threads.Tapering:

Use a taper attachment on the tap to cut the initial threads gradually, reducing the risk of tap breakage.Full threading:

Continue tapping by applying lubricant and rotating the tap until the desired hole depth is reached.

3. What factors should be considered when choosing a cutting fluid?

- Material being cut (e.g., steel, aluminum, plastic)

- Cutting operation (e.g., turning, milling, drilling)

- Tooling material (e.g., HSS, carbide, ceramic)

- Properties desired (e.g., cooling, lubrication, chip removal)

- Environmental considerations (e.g., toxicity, recyclability)

4. Explain the difference between a single-point and a multi-point cutting tool.

Single-point cutting tool:

- One cutting edge

- Used for precise cutting operations (e.g., lathe, shaper)

- Requires skilled operation and setup

Multi-point cutting tool:

- Multiple cutting edges

- Used for high-volume machining (e.g., milling, drilling)

- Easier to operate and less skill required

5. What is the purpose of a coolant in machining?

- Cooling the cutting tool and workpiece

- Lubricating the tool-to-workpiece interface

- Removing chips from the cutting zone

- Protecting the tool and workpiece from wear and tear

- Improving surface finish and tool life

6. How do you troubleshoot a threaded hole that is too loose or too tight?

Loose hole:

- Check tap drill size and ensure it is correct for the bolt size.

- Check if the bolt is the correct size and thread type.

- Consider using a thread insert or locknut to improve thread engagement.

Tight hole:

- Ensure the bolt is the correct size and thread type.

- Check if the tapped hole is clear of debris or burrs.

- Consider using a lubricant on the bolt to reduce friction.

7. Describe the types of threads and their applications.

Unified National Coarse (UNC):

General-purpose threads, used in common hardware and automotive applications.Unified National Fine (UNF):

Fine-pitched threads, used in precision applications and thin materials.Metric threads:

International standard threads, used in various industries and countries.Pipe threads:

Tapered threads, used for fluid connections and plumbing.Trapezoidal threads:

High-load threads, used in power screws, jacks, and actuators.

8. What is the difference between a burr and a chamfer?

Burr:

A sharp, raised edge that occurs on a cut surface.Chamfer:

A beveled edge that is intentionally created to reduce sharpness and improve safety.

9. Describe the principles of screw cutting on a lathe.

- Determine the thread pitch and number of threads per inch.

- Set up the lathe with the appropriate gears or lead screw.

- Mount the workpiece and center it.

- Use a lathe tool to cut the thread gradually, engaging the tool with the workpiece at the correct angle.

- Apply coolant to lubricate and cool the cutting process.

10. How do you measure a thread?

- Identify the thread standard (e.g., UNC, UNF, metric).

- Use a thread pitch gauge or thread micrometer to measure the distance between adjacent threads.

- Determine the thread diameter by measuring the outside diameter (OD) of the bolt or the inside diameter (ID) of the nut.

- For metric threads, measure the pitch in millimeters (mm) and the diameter in millimeters (mm).

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bolt Threader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bolt Threader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bolt Threaders play a significant role in manufacturing and construction industries, ensuring that bolts are threaded to the precise specifications for secure and efficient connections.

1. Thread Cutting

The primary task of a Bolt Threader is to accurately cut threads onto the blanks using a threading machine.

- Select the appropriate threading die and adjust the machine settings based on the bolt size, material, and desired thread specifications.

- Load the blank into the machine and engage the die to cut threads to the desired depth and pitch.

2. Quality Control

Bolt Threaders are responsible for maintaining high-quality standards throughout the threading process.

- Inspect the threaded bolts for defects, such as stripped threads, uneven pitch, or burrs.

- Use measuring tools such as thread gauges and micrometers to ensure that the threads meet the specified dimensions and tolerances.

3. Equipment Maintenance

Efficient operation of the threading machine is crucial to productivity and safety.

- Lubricate and clean the threading machine regularly to minimize wear and tear.

- Identify and troubleshoot any mechanical issues with the machine and perform basic repairs as needed.

4. Safety Compliance

Bolt Threaders prioritize safety in their work environment.

- Adhere to established safety protocols and wear appropriate personal protective equipment (PPE) while operating the threading machine.

- Keep the work area clean and organized to prevent accidents and maintain a safe workspace.

Interview Tips

To ace an interview for a Bolt Threader position, it’s essential to prepare thoroughly. Here are some tips to enhance your chances of success:

1. Research the Company and Position

Take the time to familiarize yourself with the company’s profile, its products or services, and the specific requirements of the Bolt Threader role.

- Visit the company’s website and social media pages to gain insights into their culture and values.

- Review the job description carefully to understand the key responsibilities and expectations.

2. Highlight Relevant Experience and Skills

In your resume and during the interview, emphasize your relevant experience and skills that align with the job requirements.

- Quantify your accomplishments using specific metrics to demonstrate your efficiency and contributions.

- If you have experience with specific threading machines or quality control techniques, mention them prominently.

3. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare your responses beforehand.

- Tell me about your experience in bolt threading and quality control.

- How do you ensure that the threaded bolts meet the specified tolerances?

- What safety measures do you follow while operating the threading machine?

4. Prepare Questions for the Interviewer

Asking thoughtful questions shows your engagement and interest in the position.

- What are the key challenges and opportunities in this role?

- What professional development opportunities are available within the company?

- Can you provide insights into the work environment and team culture?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bolt Threader interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.