Are you gearing up for a career in Bullard Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bullard Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

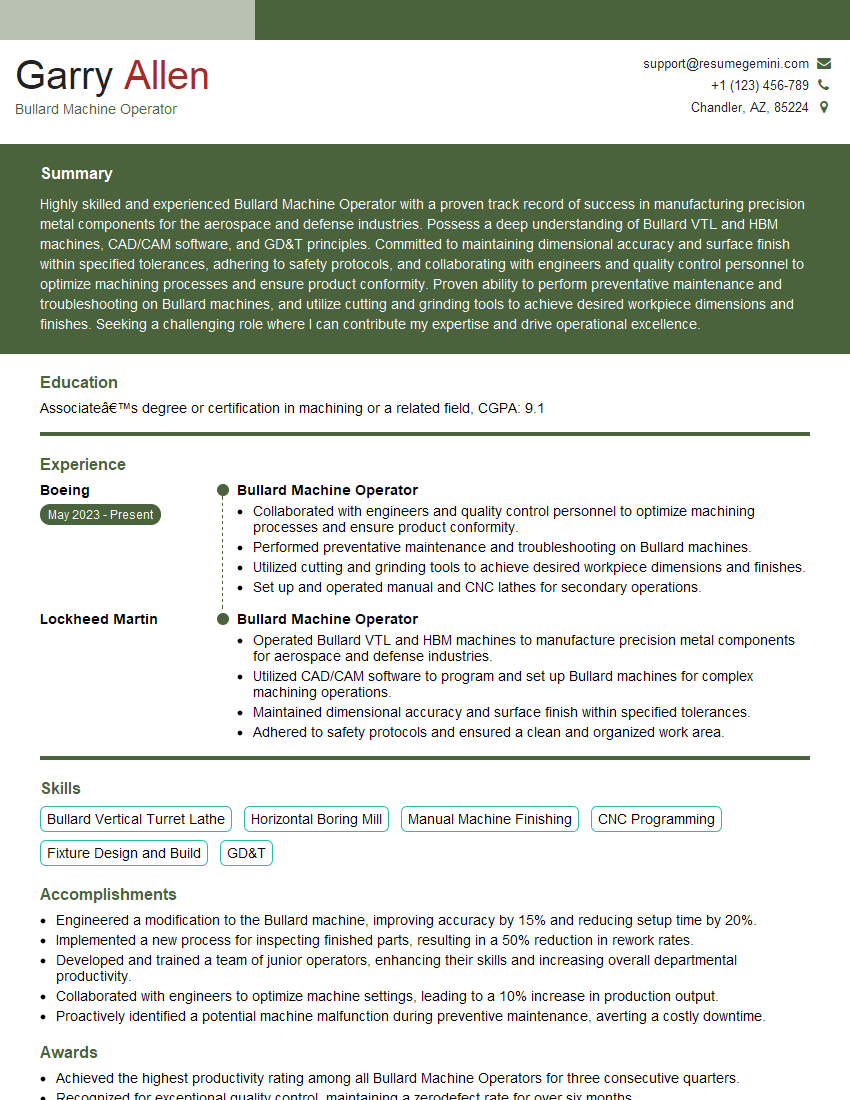

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bullard Machine Operator

1. Explain the process of setting up a Bullard Machine for a new job?

Setting up a Bullard Machine for a new job involves several steps:

- Review the job specification and drawings to determine the required tooling and workholding.

- Select and install the appropriate chuck, jaws, and tooling for the workpiece.

- Set up the machine parameters, including feed rate, spindle speed, and depth of cut.

- Install the workpiece and align it properly using indicators or other precision measuring tools.

- Zero the machine axes and ensure that all safety guards are in place.

2. What are the different types of machining operations that can be performed on a Bullard Machine?

Milling Operations

- Face milling

- Peripheral milling

- Contour milling

Boring Operations

- Rough boring

- Fine boring

- Counterboring

Facing Operations

- Flat facing

- Conical facing

- Tapered facing

3. How do you maintain the accuracy and precision of a Bullard Machine?

Maintaining the accuracy and precision of a Bullard Machine involves regular maintenance and calibration.

- Inspect and clean the machine thoroughly, including the ways, slides, and bearings.

- Lubricate all moving parts according to the manufacturer’s recommendations.

- Calibrate the machine axes using precision measuring instruments.

- Monitor tool wear and replace worn tools promptly.

- Follow proper operating procedures and use appropriate tooling for the job.

4. What are the safety precautions that you must follow when operating a Bullard Machine?

Operating a Bullard Machine safely requires adherence to the following precautions:

- Wear proper personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Ensure that the machine is properly grounded and all electrical connections are secure.

- Keep the work area clean and free of debris.

- Never operate the machine with loose clothing or jewelry that could get caught in moving parts.

- Use proper lifting techniques when handling heavy workpieces.

5. How do you troubleshoot common problems that may occur while operating a Bullard Machine?

Troubleshooting common problems on a Bullard Machine involves identifying the symptoms and taking appropriate corrective actions:

- Vibration: Check for loose components, unbalanced tooling, or worn bearings.

- Excessive tool wear: Inspect the tool for damage, adjust the feed rate or spindle speed, or check for material hardness.

- Poor surface finish: Check the tool condition, adjust the feed rate or spindle speed, or ensure that the workpiece is properly clamped.

- Inaccurate dimensions: Calibrate the machine axes, check for tool deflection, or verify the workpiece alignment.

6. What is the importance of coolant in Bullard Machine operations?

Coolant plays a crucial role in Bullard Machine operations:

- Cooling: It removes heat generated by cutting, preventing tool damage and workpiece distortion.

- Lubrication: It reduces friction between the tool and workpiece, improving tool life and surface finish.

- Flushing: It carries away chips and debris from the cutting area, maintaining a clean working environment.

7. How do you choose the right cutting tools for a Bullard Machine operation?

Selecting the appropriate cutting tools for a Bullard Machine operation depends on several factors:

- Material: Consider the hardness, machinability, and toughness of the workpiece material.

- Operation: Determine the specific machining operation (e.g., milling, boring, facing).

- Tool geometry: Choose the appropriate tool shape, rake angle, and cutting edge geometry for the desired results.

- Toolholder: Select a toolholder that provides the necessary rigidity and support for the cutting tool.

8. What is the role of a Bullard Machine Operator in a manufacturing environment?

The Bullard Machine Operator plays a vital role in manufacturing:

- Production: Operate the Bullard Machine efficiently to produce high-quality parts.

- Setup and Maintenance: Set up and maintain the machine, ensuring its accuracy and safety.

- Quality Control: Inspect parts for dimensional accuracy and surface finish.

- Problem Solving: Troubleshoot and resolve issues that arise during operation.

9. What are the qualities and skills required to be an effective Bullard Machine Operator?

Effective Bullard Machine Operators possess the following qualities and skills:

- Technical Proficiency: Strong understanding of machining principles and Bullard Machine operation.

- Problem-Solving Abilities: Ability to analyze and resolve technical issues.

- Attention to Detail: Meticulous in setting up and operating the machine for precise results.

- Safety Consciousness: Adherence to safety protocols and best practices.

- Teamwork: Ability to collaborate effectively in manufacturing settings.

10. Why are you interested in this Bullard Machine Operator position?

My interest in this Bullard Machine Operator position stems from my passion for machining and my eagerness to contribute to a manufacturing environment. With my technical proficiency in Bullard Machine operations and my dedication to producing high-quality parts, I am confident that I can make a valuable addition to your team. I am enthusiastic about the opportunity to expand my skills and contribute to the success of your operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bullard Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bullard Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bullard Machine Operators are responsible for operating Bullard vertical boring mills to machine metal parts. They use a variety of cutting tools to create complex shapes and surfaces, and they must be able to read and interpret blueprints and other technical drawings.

1. Set up and operate Bullard vertical boring mills

Bullard Machine Operators must be able to set up and operate Bullard vertical boring mills safely and efficiently. They must be able to align the machine with the workpiece, select the appropriate cutting tools, and set the correct speeds and feeds.

- Align the machine with the workpiece

- Select the appropriate cutting tools

- Set the correct speeds and feeds

2. Machine metal parts

Bullard Machine Operators use a variety of cutting tools to create complex shapes and surfaces on metal parts. They must be able to control the depth of cut, the speed of the machine, and the feed rate.

- Control the depth of cut

- Control the speed of the machine

- Control the feed rate

3. Read and interpret blueprints and other technical drawings

Bullard Machine Operators must be able to read and interpret blueprints and other technical drawings to understand the specifications of the parts they are machining. They must be able to identify the dimensions, tolerances, and other requirements of the parts.

- Identify the dimensions of the parts

- Identify the tolerances of the parts

- Identify other requirements of the parts

4. Maintain the Bullard vertical boring mill

Bullard Machine Operators are responsible for maintaining the Bullard vertical boring mill they operate. They must be able to perform routine maintenance tasks, such as cleaning, lubricating, and adjusting the machine. They must also be able to troubleshoot and repair minor problems.

- Clean the machine

- Lubricate the machine

- Adjust the machine

- Troubleshoot and repair minor problems

Interview Tips

Preparing for an interview for a Bullard Machine Operator position can be daunting, but following these tips can help you ace the interview and land the job.

1. Research the company and the position

Before you go to the interview, research the company and the position you are applying for. This will help you understand the company’s culture, its products or services, and the specific requirements of the position. This will show the interviewer that you are interested in the position and that you have taken the time to learn about the company.

- Visit the company’s website

- Read the job description carefully

- Look for news articles or other information about the company

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Prepare a brief overview of your experience and qualifications

- Research the company and the position to learn about its specific requirements

- Practice answering questions that highlight your skills and abilities

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Wear clean, pressed clothes

- Arrive on time for your interview

- Be polite and respectful to everyone you meet

4. Be yourself and be confident

The most important thing is to be yourself and be confident in your abilities. The interviewer wants to get to know you and to assess your skills and qualifications. So be honest and authentic, and let your personality shine through.

- Be genuine and authentic

- Be confident in your abilities

- Let your personality shine through

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bullard Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!