Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gear Hobber Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

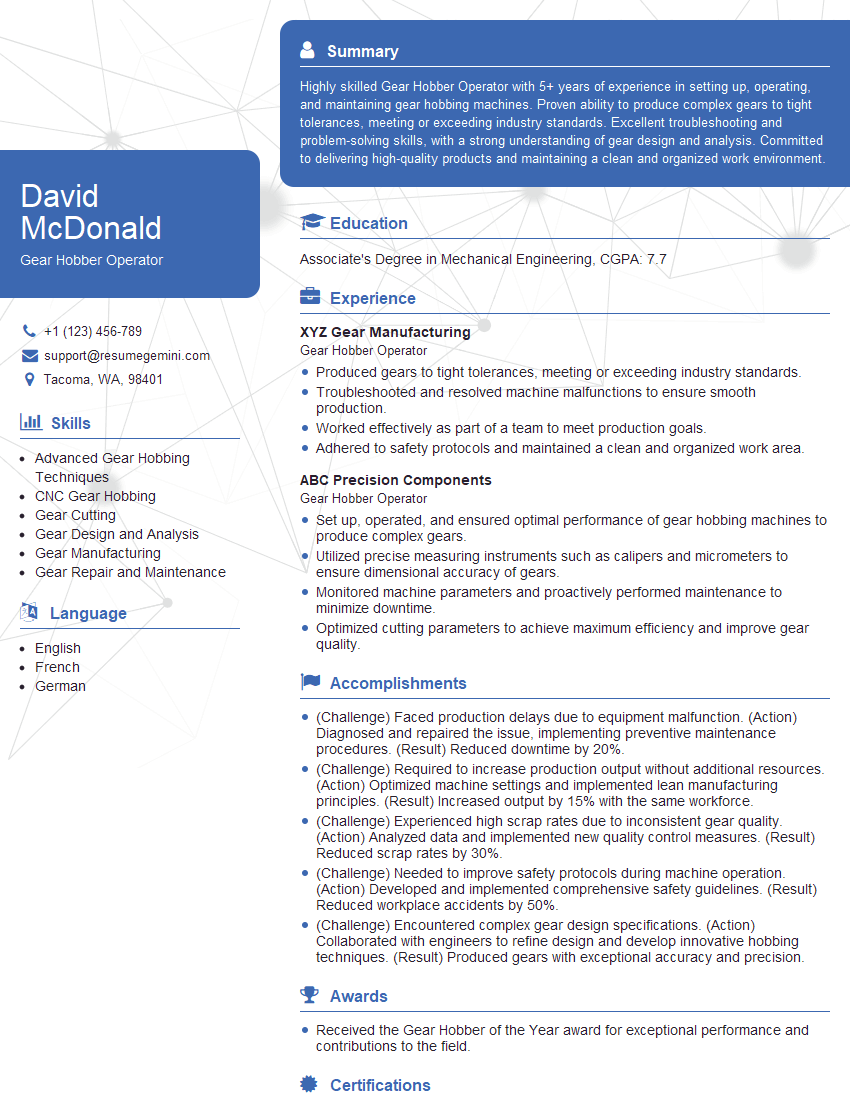

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Hobber Operator

1. What are the key steps involved in hobbing a gear?

The key steps involved in hobbing a gear include:

- Mount the workpiece on the hobbing machine.

- Align the hob with the workpiece.

- Set the hobbing parameters, such as speed, feed, and depth of cut.

- Start the hobbing process.

- Monitor the hobbing process and make adjustments as needed.

- Stop the hobbing process when the desired gear profile has been achieved.

2. What are the different types of hobs?

The different types of hobs include:

- Single-start hobs

- Multi-start hobs

- Cylindrical hobs

- Involute hobs

- Helical hobs

Additional information on hob types

- Single-start hobs have a single cutting edge and are used for cutting gears with a small number of teeth.

- Multi-start hobs have multiple cutting edges and are used for cutting gears with a large number of teeth.

- Cylindrical hobs are used for cutting gears with a cylindrical shape.

- Involute hobs are used for cutting gears with an involute tooth profile.

- Helical hobs are used for cutting gears with a helical tooth profile.

3. What are the factors that affect the quality of a hobbed gear?

The factors that affect the quality of a hobbed gear include:

- The quality of the hob

- The condition of the hobbing machine

- The hobbing parameters

- The workpiece material

4. What are the common problems that can occur during hobbing?

The common problems that can occur during hobbing include:

- Gear chatter

- Hob breakage

- Gear tooth distortion

- Surface finish problems

5. How can you troubleshoot hobbing problems?

To troubleshoot hobbing problems, you can:

- Check the hob for damage.

- Check the hobbing machine for proper alignment and operation.

- Review the hobbing parameters.

- Inspect the workpiece material for defects.

- Make adjustments as needed to correct the problem.

6. What are the safety precautions that must be taken when operating a gear hobbing machine?

The safety precautions that must be taken when operating a gear hobbing machine include:

- Wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Follow the manufacturer’s instructions for operating the machine.

- Never operate the machine when it is not in good working order.

- Be aware of the potential hazards associated with the machine, such as rotating parts and sharp edges.

7. What are the maintenance procedures for a gear hobbing machine?

The maintenance procedures for a gear hobbing machine include:

- Regularly cleaning and lubricating the machine.

- Inspecting the hob and hobbing machine for damage.

- Replacing worn parts as needed.

- Following the manufacturer’s instructions for maintenance.

8. What is the difference between hobbing and shaping?

Hobbing and shaping are two different methods of gear cutting. Hobbing is a continuous process that uses a hob to cut the gear teeth. Shaping is an intermittent process that uses a shaper cutter to cut the gear teeth.

Hobbing is typically used for high-volume production of gears. Shaping is typically used for low-volume production of gears or for gears with complex tooth profiles.

9. What is the difference between a gear hob and a gear shaper?

A gear hob is a cutting tool that has a series of cutting teeth arranged around its circumference. A gear shaper is a cutting tool that has a single cutting edge.

Hobs are used in hobbing machines to cut gears. Shapers are used in shaping machines to cut gears.

10. What are the applications of hobbing?

Hobbing is used in a variety of applications, including:

- Automotive industry

- Aerospace industry

- Heavy machinery industry

- Consumer products industry

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Hobber Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Hobber Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gear Hobber Operators are responsible for operating and maintaining gear hobbing machines, which are used to cut gears. They must have a strong understanding of gear hobbing principles, as well as the ability to operate and maintain the machines properly.

1. Set up and operate gear hobbing machines

Operators must be able to set up and operate gear hobbing machines according to the specifications of the job. This includes setting up the machine, loading the workpiece, and starting the cutting process.

- Set up and adjust the machine according to the job specifications

- Load the workpiece into the machine and secure it in place

- Start the cutting process and monitor the machine’s progress

2. Inspect and measure gears

Operators must be able to inspect and measure gears to ensure that they meet the required specifications. This includes checking the gears for accuracy, size, and finish.

- Inspect the gears for any defects or errors

- Measure the gears to ensure that they meet the required specifications

3. Maintain gear hobbing machines

Operators must be able to maintain gear hobbing machines to ensure that they are operating properly. This includes cleaning and lubricating the machines, as well as performing minor repairs.

- Clean and lubricate the machines according to the manufacturer’s instructions

- Perform minor repairs on the machines, such as replacing worn parts

4. Follow safety procedures

Operators must follow all safety procedures when operating and maintaining gear hobbing machines. This includes wearing appropriate safety gear and following lockout/tagout procedures.

- Wear appropriate safety gear, such as safety glasses and gloves

- Follow lockout/tagout procedures when performing maintenance on the machines

Interview Tips

To prepare for an interview for a Gear Hobber Operator position, you should:

1. Research the company and the position

Learn as much as you can about the company and the specific position you are applying for. This will help you to understand the company’s culture and the requirements of the job.

- Visit the company’s website and social media pages

- Read articles about the company and the industry

- Talk to people in your network who work for the company

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions in advance.

- Write out your answers to common interview questions

- Practice answering the questions out loud

- Get feedback from a friend or family member

3. Come prepared to talk about your experience

The interviewer will want to know about your experience and how it relates to the job you are applying for. Be prepared to talk about your skills, your experience, and your accomplishments.

- Highlight your experience in operating and maintaining gear hobbing machines

- Discuss your skills in inspecting and measuring gears

- Mention any experience you have in following safety procedures

4. Be professional and enthusiastic

First impressions matter, so it is important to be professional and enthusiastic during your interview. Dress appropriately, arrive on time, and be polite and respectful to the interviewer.

- Dress professionally and arrive on time for your interview

- Be polite and respectful to the interviewer

- Maintain eye contact and speak clearly

- Be enthusiastic about the position and the company

Next Step:

Now that you’re armed with the knowledge of Gear Hobber Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gear Hobber Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini