Are you gearing up for an interview for a Hydraulic Spinner position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hydraulic Spinner and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

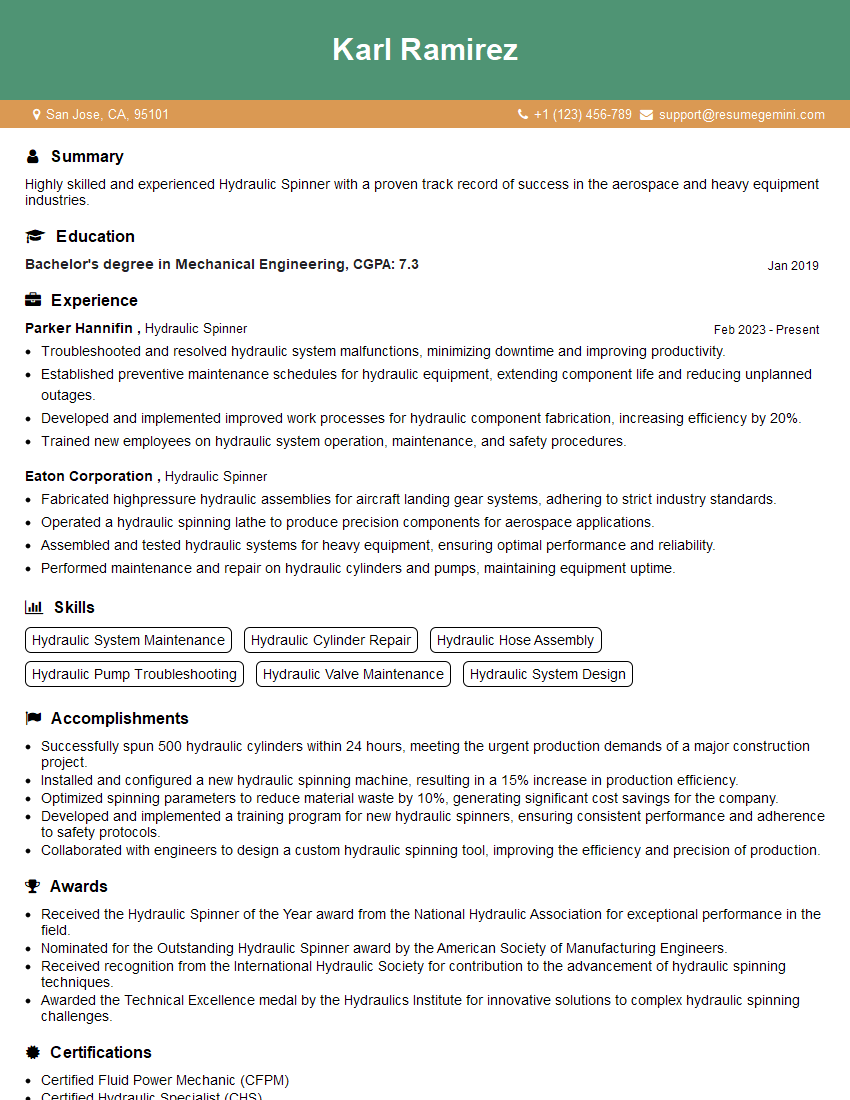

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Spinner

1. Explain the working principle of a hydraulic spinner?

A hydraulic spinner operates on the principle of centrifugal force. It consists of a rotating basket or drum that is driven by a hydraulic motor. The hydraulic fluid, typically oil, is pumped into the motor, which causes the rotor to spin at high speeds. The material to be spun is placed inside the basket, and as the basket spins, the centrifugal force generated forces the material to move towards the outer edge of the basket. This action separates the liquid from the solid particles in the material.

2. What are the different types of hydraulic spinners?

- Horizontal spinner: This type of spinner has a horizontal basket that rotates around a vertical axis. It is commonly used for spinning solids from liquids.

- Vertical spinner: This type of spinner has a vertical basket that rotates around a horizontal axis. It is used for spinning liquids from solids.

- Conical spinner: This type of spinner has a conical basket that rotates around a vertical axis. It is used for spinning solids from liquids and liquids from solids.

3. What are the factors to consider when selecting a hydraulic spinner?

When selecting a hydraulic spinner, the following factors should be considered:

- Capacity: The capacity of the spinner is determined by the size of the basket and the amount of material that can be processed in a single batch.

- Speed: The speed of the spinner determines the centrifugal force generated and the rate at which the material is separated.

- Material of construction: The material of construction of the spinner should be compatible with the materials being processed.

- Type of hydraulic fluid: The type of hydraulic fluid used in the spinner should be compatible with the materials being processed and the operating temperature.

4. What are the common maintenance tasks for a hydraulic spinner?

- Regular cleaning: The spinner should be cleaned regularly to remove any accumulated material or debris.

- Lubrication: The bearings and other moving parts of the spinner should be lubricated regularly.

- Inspection: The spinner should be inspected regularly for any signs of wear or damage.

- Hydraulic fluid replacement: The hydraulic fluid should be replaced regularly according to the manufacturer’s recommendations.

5. What are the safety precautions to be observed when operating a hydraulic spinner?

- Wear appropriate safety gear: Safety glasses, gloves, and earplugs should be worn when operating a hydraulic spinner.

- Keep clear of the spinner: Do not stand too close to the spinner while it is operating.

- Do not overload the spinner: Do not attempt to process more material than the spinner is rated for.

- Follow the manufacturer’s instructions: Always follow the manufacturer’s instructions for operating and maintaining the spinner.

6. How do you troubleshoot a hydraulic spinner that is not spinning properly?

If a hydraulic spinner is not spinning properly, the following troubleshooting steps can be taken:

- Check the power supply: Ensure that the spinner is connected to a power source and that the power switch is turned on.

- Check the hydraulic fluid level: The hydraulic fluid level should be checked and topped up if necessary.

- Check the hydraulic hoses and fittings: Inspect the hydraulic hoses and fittings for any leaks or damage.

- Check the pump: The pump should be checked to ensure that it is operating properly.

- Check the motor: The motor should be checked to ensure that it is operating properly.

7. What are the benefits of using a hydraulic spinner?

- High efficiency: Hydraulic spinners are highly efficient at separating solids from liquids.

- Fast processing time: Hydraulic spinners can process materials quickly and efficiently.

- Low maintenance: Hydraulic spinners are relatively low maintenance and easy to operate.

- Versatile: Hydraulic spinners can be used to process a wide variety of materials.

8. What are the applications of a hydraulic spinner?

- Chemical processing: Hydraulic spinners are used in the chemical industry to separate solids from liquids in a variety of processes, such as wastewater treatment, pharmaceutical production, and food processing.

- Mining: Hydraulic spinners are used in the mining industry to separate minerals from waste rock.

- Construction: Hydraulic spinners are used in the construction industry to separate sand from gravel.

- Recycling: Hydraulic spinners are used in the recycling industry to separate recyclable materials from waste.

9. How do you ensure that a hydraulic spinner is operating safely?

To ensure that a hydraulic spinner is operating safely, the following precautions should be taken:

- Regular maintenance: The spinner should be inspected and maintained regularly according to the manufacturer’s instructions.

- Proper training: Operators should be properly trained on how to operate the spinner safely.

- Follow safety procedures: All safety procedures should be followed when operating the spinner.

- Emergency stop: The spinner should be equipped with an emergency stop button that can be used to stop the spinner immediately in the event of an emergency.

10. What are the latest advancements in hydraulic spinner technology?

The latest advancements in hydraulic spinner technology include:

- Increased efficiency: New spinner designs are more efficient and can process materials faster and with less energy consumption.

- Improved durability: New materials and construction techniques have improved the durability of spinners and reduced maintenance requirements.

- Automated controls: New spinners are equipped with automated controls that make them easier to operate and maintain.

- Remote monitoring: New spinners can be remotely monitored and controlled, which allows for increased productivity and reduced downtime.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Spinner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Spinner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydraulic Spinners are responsible for operating and maintaining hydraulic spinning machines used in the fabrication of cylindrical metal components. They work closely with engineers and other technicians to ensure that the machines are operating efficiently and producing high-quality products.

1. Operate Hydraulic Spinning Machines

Spinners are responsible for setting up and operating hydraulic spinning machines. They must be able to read and interpret blueprints and technical drawings in order to determine the correct settings for the machine. They also need to be able to monitor the machine while it is in operation and make adjustments as needed.

- Set up and operate hydraulic spinning machines.

- Read and interpret blueprints and technical drawings.

- Monitor the machine while it is in operation and make adjustments as needed.

2. Produce Cylindrical Metal Components

Hydraulic spinners use hydraulic spinning machines to produce cylindrical metal components. They must be able to control the speed and pressure of the machine in order to create the desired shape and size of the component. They also need to be able to inspect the finished product to ensure that it meets the required specifications.

- Use hydraulic spinning machines to produce cylindrical metal components.

- Control the speed and pressure of the machine to create the desired shape and size of the component.

- Inspect the finished product to ensure that it meets the required specifications.

3. Maintain Hydraulic Spinning Machines

Hydraulic spinners are responsible for maintaining the hydraulic spinning machines that they operate. They must be able to perform basic maintenance tasks, such as cleaning and lubricating the machine. They also need to be able to troubleshoot and repair minor problems with the machine.

- Perform basic maintenance tasks, such as cleaning and lubricating the machine.

- Troubleshoot and repair minor problems with the machine.

4. Work Collaboratively

Hydraulic spinners often work as part of a team with engineers and other technicians. They must be able to communicate effectively with their colleagues and follow instructions. They also need to be able to work independently and take initiative.

- Work as part of a team with engineers and other technicians.

- Communicate effectively with colleagues and follow instructions.

- Work independently and take initiative.

Interview Tips

Preparing for an interview can be daunting but following a few simple tips can help you increase your chances of success. Here are some tips on how to prepare for an interview for a hydraulic spinner position:

1. Research the Company

Before you go to your interview, it is important to do your research on the company. This will help you understand the company’s culture, values, and goals. You can learn about the company by visiting its website, reading its press releases, and talking to people who work there.

- Visit the company’s website.

- Read the company’s press releases.

- Talk to people who work at the company.

2. Practice Answering Interview Questions

One of the best ways to prepare for an interview is to practice answering common interview questions. This will help you feel more confident and prepared during your interview. You can practice answering questions with a friend or family member, or you can use online resources to find practice questions.

- Practice answering common interview questions.

- Use online resources to find practice questions.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you are applying for. You should also make sure to arrive on time for your interview and be polite and respectful to everyone you meet.

- Wear clean, pressed clothes.

- Dress professionally for the job you are applying for.

- Arrive on time for your interview.

- Be polite and respectful to everyone you meet.

4. Be Enthusiastic and Positive

Hiring managers are looking for candidates who are enthusiastic and positive about the job they are applying for. Be sure to show your passion for the job and your interest in the company. You should also be positive and upbeat during your interview, even if you are nervous.

- Show your passion for the job.

- Express your interest in the company.

- Be positive and upbeat during your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hydraulic Spinner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!