Feeling lost in a sea of interview questions? Landed that dream interview for Lap Cutter Truer Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lap Cutter Truer Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

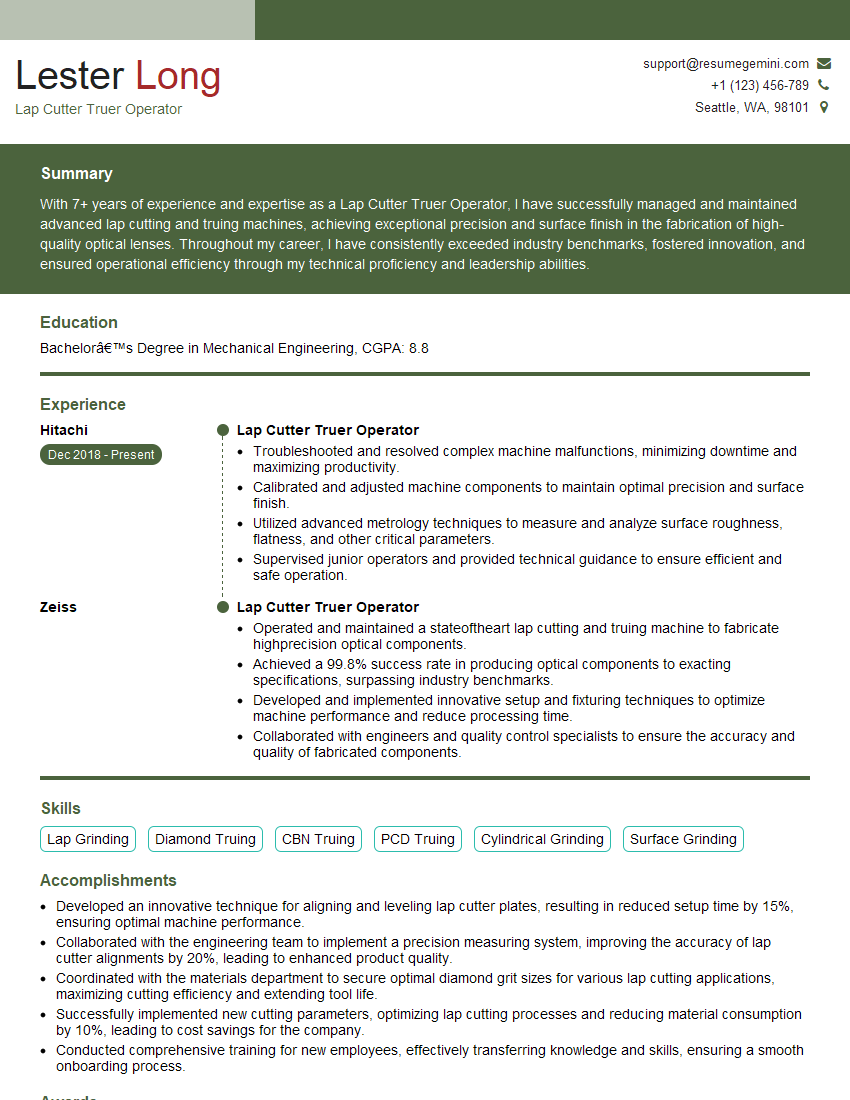

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lap Cutter Truer Operator

1. Describe the process of setting up and operating a Lap Cutter Truer machine?

- Mount the diamond blade on the machine and ensure it is properly aligned and balanced.

- Secure the workpiece on the turntable and adjust the cutting depth and speed.

- Start the machine and allow the diamond blade to rotate freely.

- Gradually engage the workpiece with the blade and maintain a constant feed rate.

- Monitor the cutting process and make any necessary adjustments to achieve the desired surface finish.

2. How do you ensure that the machine is operating within safe parameters?

Regular Maintenance

- Inspect the machine regularly for any signs of wear or damage.

- Lubricate all moving parts according to the manufacturer’s recommendations.

Safety Precautions

- Wear appropriate safety gear, including gloves, eye protection, and earplugs.

- Ensure that the machine is properly grounded to prevent electrical hazards.

- Never operate the machine under the influence of drugs or alcohol.

3. What are the common types of defects that can occur during lap cutting and truing, and how do you prevent them?

- Chatter: Caused by excessive vibration. Use sharp blades, maintain proper cutting speed, and ensure that the workpiece is securely clamped.

- Burn marks: Caused by excessive heat. Reduce the cutting speed, increase the feed rate, and use a coolant to dissipate heat.

- Cracks: Caused by excessive stress. Use a blade with a smaller cutting area, reduce the cutting depth, and use a slower feed rate.

4. How do you maintain the accuracy and precision of the machine?

- Regularly calibrate the machine using a precision gauge block.

- Use high-quality diamond blades that are sharp and properly aligned.

- Maintain a constant cutting speed and feed rate.

- Monitor the machine’s performance and make adjustments as needed.

5. What are the different types of materials that can be processed using a Lap Cutter Truer machine, and what are the specific considerations for each?

- Metals: Require sharp blades and slow feed rates to prevent damage to the workpiece.

- Ceramics: Require higher cutting speeds and a continuous feed to achieve a smooth surface finish.

- Glass: Require special diamond blades designed specifically for cutting glass.

6. How do you troubleshoot common problems that may arise while operating a Lap Cutter Truer machine?

- Machine not starting: Check the power supply, fuses, and motor.

- Blade not cutting properly: Check the blade sharpness, alignment, and cutting speed.

- Excessive vibration: Check the machine’s balance, alignment, and mounting.

7. What are the key safety precautions that must be followed when operating a Lap Cutter Truer machine?

- Wear appropriate safety gear, including gloves, eye protection, and earplugs.

- Ensure that the machine is properly grounded to prevent electrical hazards.

- Never operate the machine under the influence of drugs or alcohol.

- Keep the work area clean and free of debris.

- Follow all manufacturer’s instructions and guidelines.

8. How do you perform routine maintenance and calibration of a Lap Cutter Truer machine?

- Clean and lubricate the machine according to the manufacturer’s recommendations.

- Check the blade sharpness and alignment regularly.

- Calibrate the machine using a precision gauge block.

- Inspect the electrical components and wiring for any signs of damage.

9. What are the different types of cutting fluids that can be used with a Lap Cutter Truer machine, and how do you determine the best option for a particular application?

- Water-based: Cost-effective and environmentally friendly, suitable for most materials.

- Oil-based: Provide better lubrication and cooling, suitable for cutting metals.

- Synthetic: Offer a combination of properties from water-based and oil-based fluids.

10. How do you optimize the cutting process to achieve the desired surface finish and accuracy?

- Select the appropriate diamond blade and cutting fluid.

- Adjust the cutting speed, feed rate, and cutting depth based on the material and desired finish.

- Use a precision gauge block to ensure accurate cutting.

- Monitor the cutting process and make adjustments as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lap Cutter Truer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lap Cutter Truer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lap Cutter Truer Operators play a crucial role in precision grinding applications, ensuring the smooth and accurate operation of the machines. Their key responsibilities include:

1. Machine Operation

Responsible for setting up, operating, and maintaining lap cutter truer machines. This involves:

- Loading and positioning workpieces on the machine

- Selecting appropriate tooling and grinding parameters

- Monitoring the grinding process and making adjustments as necessary

2. Quality Control

Ensuring the quality of the finished products by:

- Inspecting workpieces for accuracy, surface finish, and dimensional tolerances

- Making necessary adjustments to the machine or process to meet quality standards

3. Machine Maintenance

Performing routine maintenance and troubleshooting on the lap cutter truer machine, including:

- Lubricating and cleaning the machine

- Identifying and repairing minor issues

- Reporting major issues to supervisors for prompt resolution

4. Communication and Collaboration

Collaborating with other team members, such as engineers, setup operators, and quality control personnel, to ensure seamless production

- Communicating machine status and any issues encountered

- Providing feedback on process improvements

Interview Tips

To ace the interview for a Lap Cutter Truer Operator position, candidates should prepare thoroughly and demonstrate their skills and knowledge effectively. Here are some tips to help you prepare:

1. Research the Company and Position

Take the time to research the company’s website, LinkedIn page, and industry news to learn about their business, culture, and current projects. This will help you tailor your answers to the specific requirements of the position.

- Identify the key responsibilities and qualifications for the role.

- Prepare examples from your previous experience that demonstrate your proficiency in these areas.

2. Practice Your Technical Skills

Be prepared to discuss your technical knowledge and skills related to lap cutter truer machine operation. Focus on your understanding of:

- Machine setup and operation procedures

- Tooling selection and grinding parameters

- Quality control techniques and inspection methods

- Machine maintenance and troubleshooting

3. Emphasize Safety and Quality

Safety and quality are paramount in manufacturing environments. Highlight your commitment to:

- Following all safety protocols and regulations

- Maintaining a clean and organized work area

- Consistently producing high-quality work that meets or exceeds customer expectations

4. Prepare for Behavioral Questions

Interviewers often ask behavioral questions to assess your soft skills, such as communication, problem-solving, and teamwork. Use the STAR method (Situation, Task, Action, Result) to answer these questions effectively:

- Describe a specific situation you encountered.

- Explain the task you were responsible for.

- Describe the actions you took to address the situation.

- Quantify the results of your actions, if possible.

5. Dress Professionally and Be Courteous

First impressions matter. Dress professionally and arrive on time for the interview. Be courteous and respectful to everyone you meet, including the receptionist and other employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lap Cutter Truer Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.