Are you gearing up for an interview for a Lathe Hand position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lathe Hand and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

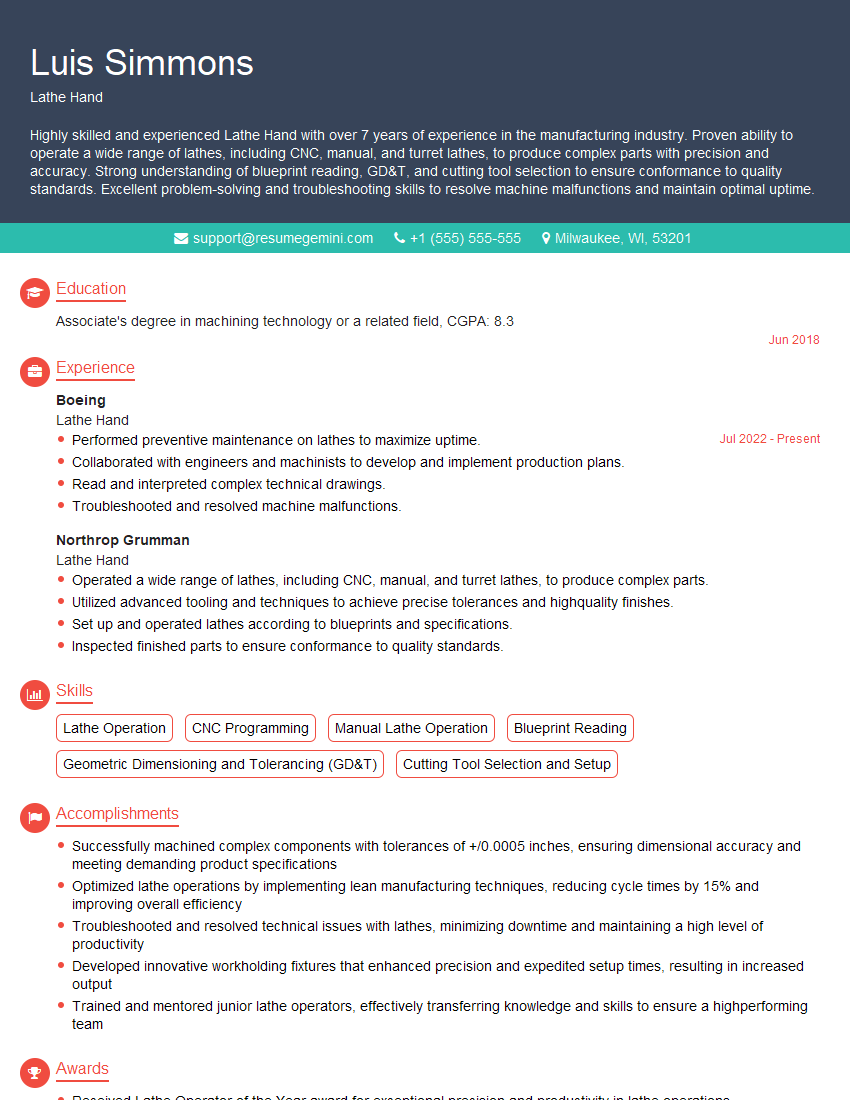

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lathe Hand

1. Explain the different types of lathes and their uses?

A lathe is a machine that rotates a workpiece around its axis to perform various operations such as cutting, sanding, drilling, and knurling. There are several types of lathes, each designed for specific applications and materials.

- Engine lathes: These are the most common type of lathe, used for general-purpose machining operations. They have a bed, headstock, tailstock, and carriage that supports the cutting tool.

- Turret lathes: These lathes have a turret that holds multiple cutting tools, allowing for quick and easy tool changes. They are used for high-volume production of small parts.

- CNC lathes: These lathes are computer-controlled, allowing for precise and automated machining operations. They are used for complex and high-precision work.

2. What are the different types of cutting tools used in lathe operations?

Various cutting tools are used in lathe operations, each designed for specific applications and materials.

- Turning tools: These tools are used for external and internal turning operations, removing material from the workpiece to create cylindrical or conical shapes.

- Facing tools: These tools are used to create flat surfaces on the workpiece, such as the end faces of a shaft or the face of a flange.

- Boring tools: These tools are used to enlarge existing holes or create new holes in the workpiece.

- Threading tools: These tools are used to cut threads on the workpiece, creating external or internal threads for fastening.

3. Explain the process of setting up a lathe machine for a specific operation?

- Mounting the workpiece: Secure the workpiece in the chuck or between the centers of the lathe.

- Selecting the appropriate cutting tool: Choose the correct cutting tool for the operation and install it in the tool holder.

- Setting the cutting speed and feed rate: Determine the optimal cutting speed and feed rate based on the material and cutting tool being used.

- Adjusting the tool position: Position the cutting tool correctly relative to the workpiece, considering factors such as the desired cutting depth and tool offset.

- Lubrication: Apply cutting fluid or lubricant to reduce friction and improve tool life.

4. Describe the safety precautions that must be taken when operating a lathe?

- Wear proper safety gear: This includes safety glasses, gloves, and protective clothing to prevent injuries from flying chips or rotating components.

- Securely mount the workpiece: Ensure that the workpiece is firmly held to prevent it from slipping or flying out during operation.

- Keep the work area clean and organized: Remove any loose tools or debris from the work area to prevent tripping or other hazards.

- Operate the lathe cautiously: Avoid sudden movements or excessive force, and always be aware of the rotating components.

- Never leave the lathe unattended while it is running: Stay close to the machine and monitor its operation to prevent accidents.

5. Explain the importance of tool geometry and its impact on cutting performance?

Tool geometry plays a crucial role in the efficiency and quality of cutting operations. The geometry of the cutting tool, such as its rake angle, clearance angle, and cutting edge shape, directly influences factors like:

- Cutting forces: The geometry affects the forces generated during cutting, which can impact the machine load and workpiece deflection.

- Chip formation: The tool geometry influences the shape and size of the chips produced during cutting, which can affect surface finish and tool life.

- Tool wear: Proper tool geometry helps reduce wear and tear on the cutting tool, extending its lifespan and ensuring consistent cutting performance.

6. Describe the different types of materials that can be machined on a lathe?

Lathes can be used to machine a wide range of materials, including:

- Metals: Ferrous metals (e.g., steel, cast iron) and non-ferrous metals (e.g., aluminum, brass, copper)

- Plastics: Various types of plastics, such as acrylic, polycarbonate, and nylon

- Wood: Different types of wood, including hardwoods and softwoods

- Other materials: Certain composites and ceramics can also be machined on lathes with appropriate tooling.

7. Explain the concept of surface finish and how it is achieved in lathe operations?

Surface finish refers to the quality and smoothness of the machined surface. It is influenced by factors such as:

- Cutting tool geometry: The sharpness and shape of the cutting tool affect the surface finish.

- Cutting parameters: Feed rate, cutting speed, and depth of cut can impact surface finish.

- Workpiece material: Different materials exhibit varying surface finishes when machined.

- Lubrication: Proper lubrication reduces friction and helps achieve a smoother surface finish.

8. Explain the process of knurling and its applications?

Knurling is a process of creating a textured or patterned surface on a workpiece. It is commonly used to improve grip or provide a decorative finish. The process involves using a knurling tool that has a series of evenly spaced ridges or serrations.

- Setup: The workpiece is mounted on the lathe and the knurling tool is positioned.

- Pressure application: The knurling tool is pressed against the rotating workpiece.

- Pattern formation: The ridges of the knurling tool create a corresponding pattern on the workpiece surface.

9. Describe the importance of coolant in lathe operations?

Coolant is a liquid or gaseous substance used in lathe operations to:

- Reduce friction and heat: Coolant helps dissipate heat generated during cutting, preventing tool wear and workpiece distortion.

- Lubricate the cutting tool and workpiece: Coolant reduces friction between the tool and workpiece, improving cutting efficiency and extending tool life.

- Flush away chips and debris: Coolant helps remove chips and debris from the cutting zone, preventing clogging and ensuring a clean cutting environment.

10. Explain the role of a tailstock in lathe operations?

The tailstock is a movable part of the lathe that supports the workpiece on the opposite end of the spindle. Its primary functions are:

- Workpiece support: The tailstock provides additional support for long or slender workpieces, preventing deflection and ensuring machining accuracy.

- Drilling and boring: The tailstock can be used to hold drilling or boring tools, allowing for precise hole making operations.

- Taper turning: By offsetting the tailstock, it is possible to create tapered surfaces on the workpiece.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lathe Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lathe Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lathe hands are experts in operating lathe machines to create cylindrical and complex parts, which are crucial components used in various industries. To succeed in this role, candidates should possess a deep understanding of lathe operations and a meticulous approach to ensure precision and accuracy.

1. Machine Operation and Setup

Lathe hands are entrusted with the responsibility of setting up, operating, and maintaining lathe machines. This includes:

- Selecting and installing the appropriate tools, such as cutting bits, drills, and reamers, based on the specifications of the workpiece.

- Adjusting machine settings, such as speed, feed rate, and depth of cut, to optimize performance and achieve desired results.

- Monitoring machine operation during the cutting process to ensure smooth and efficient production.

2. Material Handling

Lathe hands are responsible for handling various types of materials, including metals, plastics, and wood. Their duties include:

- Loading and unloading workpieces into and out of the lathe machine, ensuring proper alignment and secure placement.

- Inspecting workpieces for defects or damage before and after machining to maintain quality standards.

- Storing and organizing materials in a safe and efficient manner, minimizing waste and maximizing productivity.

3. Measurement and Inspection

Lathe hands play a critical role in ensuring the accuracy and precision of machined parts. They are responsible for:

- Measuring and inspecting workpieces using various measuring instruments, such as calipers, micrometers, and height gauges.

- Comparing actual measurements to specified tolerances and making adjustments to the machine or cutting process as needed.

- Maintaining accurate records of measurements and inspections to ensure traceability and compliance with quality standards.

4. Maintenance and Troubleshooting

Lathe hands are also responsible for performing basic maintenance and troubleshooting tasks to keep machines in optimal condition. This includes:

- Cleaning, lubricating, and adjusting lathe machines regularly to prevent breakdowns and ensure smooth operation.

- Identifying and resolving minor issues, such as tool wear or machine vibration, to minimize downtime and maintain productivity.

- Reporting major issues or breakdowns to supervisors or maintenance personnel for timely repairs.

Interview Tips

Preparing for a lathe hand interview requires a combination of technical knowledge and a clear understanding of the role’s responsibilities. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company’s background, industry, and products. This knowledge will help you understand the context of the role and tailor your answers accordingly.

2. Highlight Your Skills and Experience

During the interview, emphasize your technical skills and experience in lathe operations. Provide specific examples of your work, such as the types of parts you have machined, the machines you have operated, and the accuracy you have achieved.

3. Showcase Your Attention to Detail

Lathe hands must possess a keen eye for detail and a commitment to precision. In the interview, highlight your ability to measure and inspect workpieces accurately, as well as your attention to safety and quality control.

4. Prepare for Technical Questions

Be prepared to answer technical questions about lathe operations, such as:

- How do you prepare a lathe machine for a specific job?

- What are the different types of cutting tools used in lathe operations?

- How do you ensure the accuracy and precision of machined parts?

5. Practice Common Interview Questions

In addition to technical questions, prepare for common interview questions such as:

- Tell me about yourself and your experience.

- Why are you interested in this position?

- What are your strengths and weaknesses?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lathe Hand interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!