Feeling lost in a sea of interview questions? Landed that dream interview for Mult-Au-Matic Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mult-Au-Matic Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

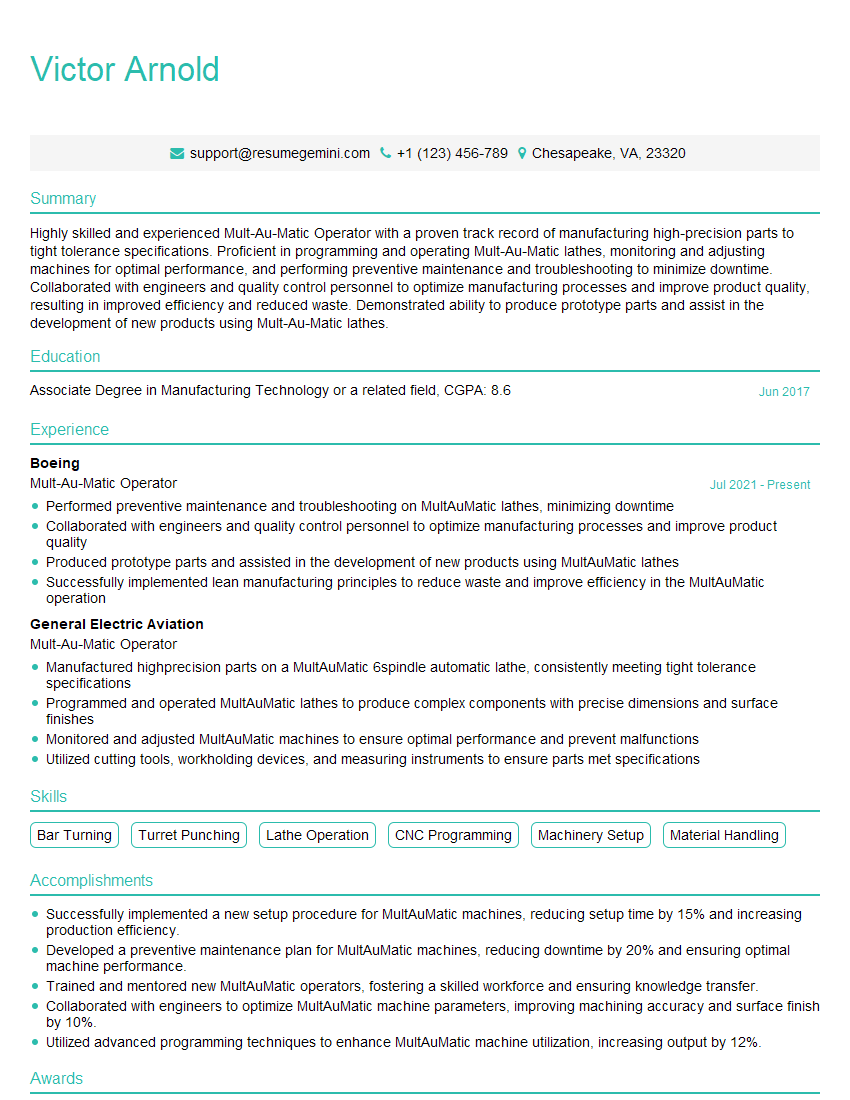

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mult-Au-Matic Operator

1. What are the key responsibilities of a Mult-Au-Matic Operator?

The key responsibilities of a Mult-Au-Matic Operator typically include:

- Setting up and operating Mult-Au-Matic machines to produce precision parts according to specifications.

- Monitoring machines during operation and making adjustments as necessary to maintain quality and productivity.

- Inspecting and measuring parts to ensure they meet specifications and customer requirements.

- Maintaining a clean and organized work area, including cleaning and lubricating machines as required.

- Following safety protocols and reporting any potential hazards or accidents to the appropriate personnel.

2. Can you describe the different types of Mult-Au-Matic machines and the operations they can perform?

Setup and Operation

- Explain the process of setting up a Mult-Au-Matic machine, including mounting cutting tools and setting machine parameters.

- Describe the different types of cutting operations that can be performed on a Mult-Au-Matic machine, such as turning, drilling, milling, and threading.

Maintenance and Troubleshooting

- Explain the importance of regular maintenance for Mult-Au-Matic machines and describe the typical maintenance procedures.

- Describe common troubleshooting techniques for resolving issues with Mult-Au-Matic machines, including identifying and correcting errors in machine setup or operation.

3. What are the common materials that are processed using Mult-Au-Matic machines?

Mult-Au-Matic machines are commonly used to process a variety of materials, including:

- Metals: steel, stainless steel, aluminum, brass, and copper.

- Plastics: nylon, polyethylene, and polycarbonate.

- Other materials: wood, composites, and ceramics.

4. How do you ensure the accuracy and precision of parts produced on a Mult-Au-Matic machine?

Ensuring the accuracy and precision of parts produced on a Mult-Au-Matic machine requires attention to several factors, including:

- Proper machine setup and calibration.

- Use of sharp and properly sized cutting tools.

- Careful selection of machining parameters, such as speeds and feeds.

- Regular inspection and adjustment of the machine during operation.

- Adherence to quality control procedures and documentation.

5. What safety protocols should be followed when operating a Mult-Au-Matic machine?

To ensure a safe work environment when operating a Mult-Au-Matic machine, it is crucial to adhere to the following safety protocols:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Follow proper lockout/tagout procedures before performing maintenance or repairs.

- Be aware of the location of emergency stop buttons and know how to use them.

- Never operate a machine that is malfunctioning or has not been properly inspected.

- Report any accidents or near-misses to the appropriate personnel immediately.

6. How do you handle production issues or machine breakdowns that occur during operation?

When production issues or machine breakdowns occur during operation, it is important to take the following steps:

- Identify the cause of the issue or breakdown.

- Implement appropriate corrective actions to resolve the issue.

- Document the issue and the corrective actions taken.

- Notify the appropriate personnel, such as the supervisor or maintenance team.

- Follow up to ensure that the issue has been resolved and that production can resume smoothly.

7. Can you describe a situation where you successfully resolved a complex problem related to the operation of a Mult-Au-Matic machine?

Describe a specific instance where you encountered a complex problem related to the operation of a Mult-Au-Matic machine and explain how you successfully resolved it. Highlight your troubleshooting skills and problem-solving abilities.

8. How do you stay up-to-date with the latest advancements in Mult-Au-Matic technology and best practices?

Explain how you stay informed about new technologies, industry trends, and best practices related to Mult-Au-Matic machines. Mention any relevant training, seminars, or professional development activities you have participated in.

9. What are the key performance indicators (KPIs) that you track to measure your productivity and efficiency as a Mult-Au-Matic Operator?

List the KPIs that you monitor to assess your performance, such as production output, machine uptime, scrap rate, and quality metrics. Explain how you use this data to identify areas for improvement and optimize your work processes.

10. How do you handle working in a team environment and collaborating with other production staff?

Describe your experience working in a team environment and how you contribute to the overall success of the production team. Highlight your communication, teamwork, and problem-solving skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mult-Au-Matic Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mult-Au-Matic Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mult-Au-Matic Operators play a vital role in manufacturing by operating complex, multi-spindle automatic screw machines. These machines produce a wide range of high-volume, precision parts used in various industries.

1. Machine Operation

Operators monitor and control the machines, ensuring they run efficiently and produce parts to specified tolerances.

- Set up and adjust machines according to job specifications.

- Monitor machine operations, adjusting parameters and making necessary adjustments.

2. Quality Control

Operators perform quality checks on parts produced by the machines, ensuring they meet specifications and standards.

- Inspect parts using measuring tools and gauges.

- Identify and correct any defects or deviations from specifications.

3. Maintenance and Troubleshooting

Operators perform basic maintenance and troubleshooting to keep the machines in good working condition.

- Clean and lubricate machines.

- Troubleshoot and resolve operational issues, ensuring smooth production.

4. Production Optimization

Operators continuously work to optimize production efficiency and minimize waste.

- Identify and implement process improvements to increase productivity.

- Analyze production data to identify areas for improvement.

Interview Tips

To ace your interview for a Mult-Au-Matic Operator position, follow these tips:

1. Preparation

Familiarize yourself with the job description and research the company’s operations. Practice answering common interview questions related to your skills and experience.

- Highlight your experience in operating Mult-Au-Matic machines or similar equipment.

- Emphasize your attention to detail and commitment to producing quality parts.

2. Confidence and Communication

Approach the interview with confidence and enthusiasm. Communicate your skills and experience clearly and effectively, providing specific examples of your successes.

- Be prepared to discuss your ability to work independently and as part of a team.

- Demonstrate your problem-solving and decision-making capabilities.

3. Show Curiosity and Eagerness

Ask thoughtful questions about the company, the position, and the industry. This indicates your interest and eagerness to learn and grow.

- Inquire about the company’s production goals and how you can contribute to their achievement.

- Ask about the company’s plans for future investments and advancements in automation.

4. Follow Up

After the interview, promptly follow up with a thank-you note to the interviewer. Reiterate your interest in the position and highlight key points you discussed during the interview.

- In your note, summarize how your skills and experience align with the company’s needs.

- Reiterate your enthusiasm for the opportunity and your commitment to contributing to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mult-Au-Matic Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!