Feeling lost in a sea of interview questions? Landed that dream interview for Multiple Spindle Screw Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Multiple Spindle Screw Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

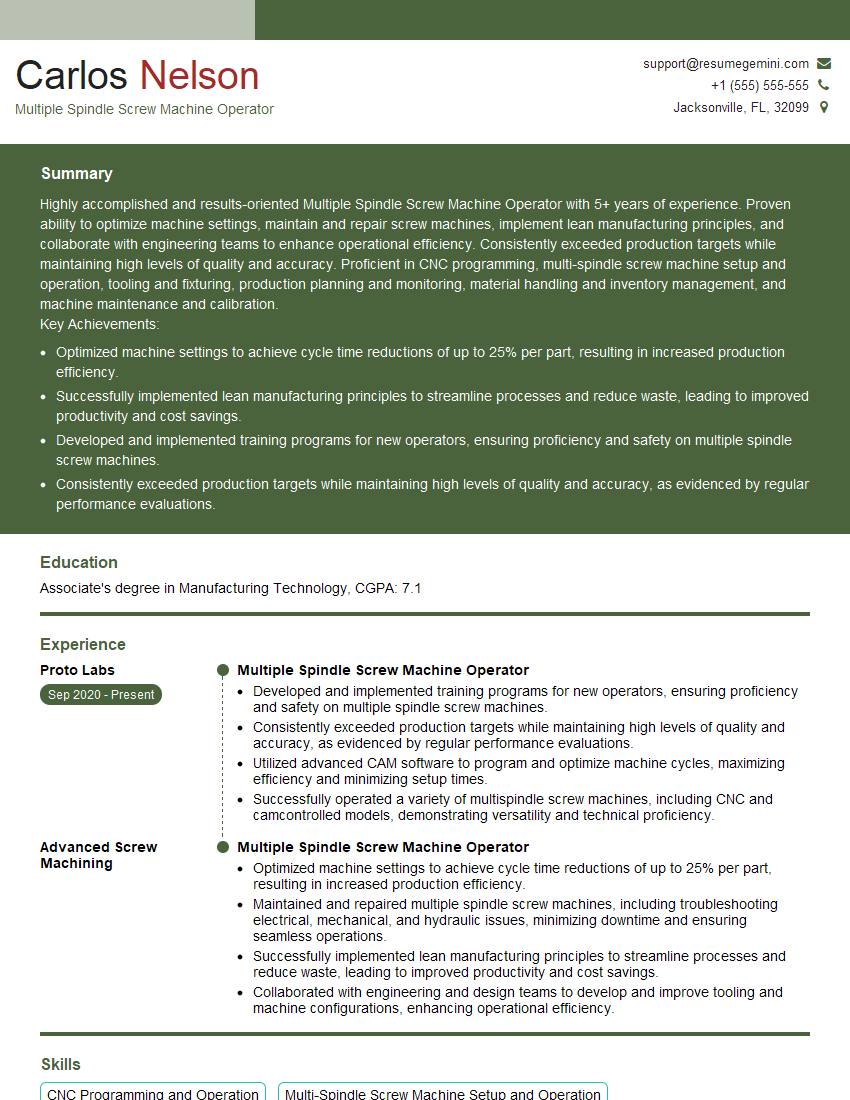

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Multiple Spindle Screw Machine Operator

1. What are the key differences between a single-spindle screw machine and a multiple-spindle screw machine?

- Number of spindles: Single-spindle machines have one spindle, while multiple-spindle machines have multiple spindles (typically 4-8).

- Production rate: Multiple-spindle machines can produce parts faster than single-spindle machines due to the increased number of spindles.

- Complexity of parts: Multiple-spindle machines are capable of producing more complex parts than single-spindle machines due to the increased number of spindles and the ability to perform multiple operations simultaneously.

2. What are the different types of tooling used on a multiple-spindle screw machine?

Cutting tools

- Drills

- Taps

- Mills

- Saws

- Knurls

Forming tools

- Roll dies

- Cut-off tools

- Forming slides

3. How do you set up a multiple-spindle screw machine?

- Install the tooling.

- Set the speeds and feeds.

- Load the material.

- Run the machine.

4. How do you troubleshoot a multiple-spindle screw machine?

- Check the tooling for wear or damage.

- Check the speeds and feeds.

- Check the material for defects.

- Check the machine for mechanical problems.

5. What are the safety precautions that must be taken when operating a multiple-spindle screw machine?

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Keep the work area clean and free of debris.

- Never operate the machine when it is not properly guarded.

- Be aware of the location of the emergency stop button.

6. What is the difference between a bar feed and a magazine feed?

- Bar feed: A bar feed is a device that automatically feeds bar stock into the machine.

- Magazine feed: A magazine feed is a device that holds a stack of pre-cut blanks and feeds them into the machine one at a time.

7. What are the different types of materials that can be machined on a multiple-spindle screw machine?

- Metals: Steel, brass, aluminum, copper

- Plastics: ABS, PVC, nylon

- Wood

8. What are the different types of parts that can be produced on a multiple-spindle screw machine?

- Screws

- Bolts

- Nuts

- Washers

- Pins

- Gears

9. What are the advantages of using a multiple-spindle screw machine?

- Increased production rate

- Improved accuracy

- Reduced labor costs

- Increased flexibility

10. What are the disadvantages of using a multiple-spindle screw machine?

- Higher initial cost

- Increased maintenance costs

- Requires skilled operators

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Multiple Spindle Screw Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Multiple Spindle Screw Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Multiple Spindle Screw Machine Operators play a critical role in manufacturing industries, operating complex machinery to produce precision parts. Their primary responsibilities include:

1. Machine Operation

Operate multiple spindle screw machines to produce components according to specifications.

- Set up and adjust machines, including tool selection, spindle speeds, and feed rates.

- Monitor machine functions and make necessary adjustments to ensure efficient operation.

2. Production Monitoring

Track production output and identify any deviations from targets.

- Monitor material flow and ensure timely delivery of raw materials.

- Inspect finished products for quality and accuracy.

3. Maintenance and Troubleshooting

Perform preventive maintenance on machines to minimize downtime.

- Clean and lubricate machines according to manufacturer’s guidelines.

- Troubleshoot and resolve machine malfunctions promptly.

- Maintain a clean and organized work area.

4. Safety Compliance

Adhere to safety protocols and regulations to ensure a safe work environment.

- Wear appropriate personal protective equipment.

- Follow established safety procedures for machine operation and maintenance.

- Report any safety hazards or concerns promptly.

Interview Tips

Preparing for an interview can significantly enhance your chances of success. Here are some tips to help you ace the interview for a Multiple Spindle Screw Machine Operator position:

1. Research the Company and Position

Gather information about the company’s industry, products, and culture.

- Visit the company website and social media profiles.

- Review the job description carefully to understand the specific requirements.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job.

- Quantify your accomplishments using specific metrics whenever possible.

- Provide examples of your ability to operate and maintain multiple spindle screw machines.

- Showcase your problem-solving and troubleshooting capabilities.

3. Practice Common Interview Questions

Prepare for typical interview questions by researching common questions and practicing your responses.

- Tell me about a time when you faced a challenge in operating a multiple spindle screw machine.

- How do you ensure the accuracy and quality of the parts you produce?

- Describe your experience in troubleshooting and repairing machine malfunctions.

4. Be Prepared to Discuss Safety

Emphasize your commitment to safety by highlighting your knowledge of safety protocols.

- Describe your experience in following safety procedures in a manufacturing environment.

- Explain how you would handle a potential safety hazard or concern.

5. Dress Appropriately and Be Punctual

Make a positive first impression by dressing professionally and arriving on time for your interview.

- Wear clothes that are comfortable and allow you to move freely.

- Arrive at the interview venue a few minutes early to show your respect for the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Multiple Spindle Screw Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!