Are you gearing up for an interview for a Planer Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Planer Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

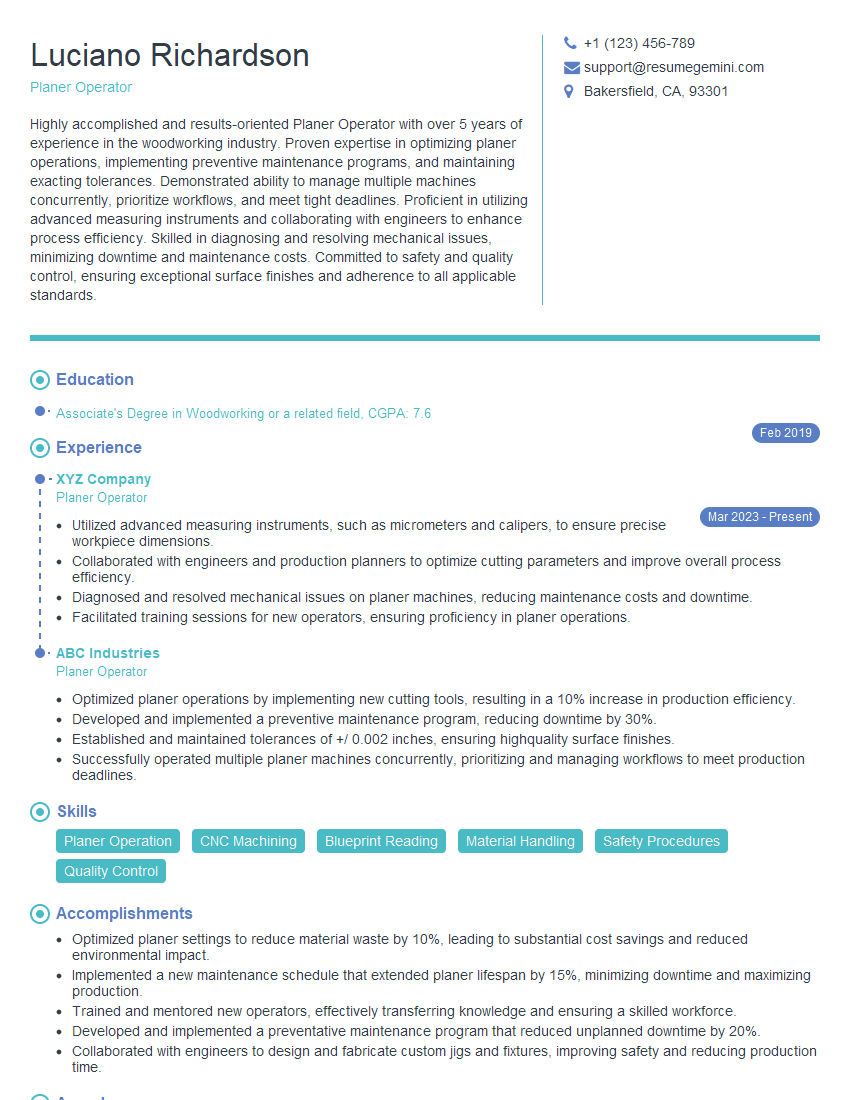

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Planer Operator

1. Describe the steps involved in preparing a subgrade for planing?

In preparing a subgrade for planing, I follow these steps:

- Inspection: Assess the subgrade’s condition, noting any irregularities, soft spots, or damaged areas.

- Patching and Repairing: Address any deficiencies by patching damaged areas and filling in soft spots with suitable material.

- Compaction: Compact the subgrade to achieve the desired density and stability to support the pavement.

- Proof Rolling: Use a heavy roller to identify and correct any weak or unstable areas that may require additional compaction or repairs.

- Grading: Fine-grade the subgrade to the specified elevations and slopes using a motor grader or other equipment.

- Moisture Control: Adjust moisture content as needed to optimize compaction and prevent future problems.

2. How do you calculate the required thickness of the asphalt overlay?

Asphalt Overlay Thickness Calculation Considerations:

- Existing Pavement Condition: Evaluate the current condition, including any cracks, ruts, or damage.

- Traffic Volume and Load: Determine the expected traffic load and its impact on the pavement.

- Subgrade Strength: Assess the supporting capacity of the subgrade to ensure it can withstand the overlay.

- Asphalt Type and Properties: Consider the specific asphalt mix being used and its thickness requirements.

- Design Life: Estimate the desired lifespan of the overlay and select a thickness accordingly.

Calculation Methods:

- Empirical Methods: Use formulas based on historical data and experience to estimate the required thickness.

- Mechanistic-Empirical Methods: Consider factors such as traffic loading, pavement structure, and material properties to calculate the thickness.

3. What are the different types of planers and their uses?

There are several types of planers used for different purposes:

- Cold Planers: Designed for removing existing asphalt pavements, typically used for resurfacing or rehabilitation projects.

- Hot Planers: Remove asphalt while heating it, allowing for faster removal and a smoother surface. Ideal for large-scale projects or where precise surface quality is required.

- Concrete Planers: Specifically designed for removing concrete pavements, using diamond-tipped cutting tools.

- Ride Quality Planers: Improve the smoothness of existing pavements by removing minor irregularities, bumps, or grooves.

4. How do you set the cutting depth and angle of the planer?

Setting the cutting depth and angle of the planer is crucial for achieving the desired results:

- Cutting Depth: Determine the required depth of removal based on the overlay thickness and existing pavement condition.

- Cutting Angle: Select the appropriate cutting angle to ensure a smooth, consistent surface. For most applications, an angle of 15-25 degrees is optimal.

- Adjustment Procedures: Refer to the manufacturer’s specifications and use the provided adjustment mechanisms on the planer to set both the depth and angle precisely.

5. How do you control the speed and feed rate of the planer?

Controlling the speed and feed rate of the planer is essential for efficient operation and optimal results:

- Speed: Adjust the planer’s speed based on the cutting depth, material hardness, and desired surface finish.

- Feed Rate: Determine the appropriate feed rate to ensure the planer removes material consistently without overloading or stalling.

- Control Mechanisms: Use the onboard controls or manual adjustments to regulate both speed and feed rate.

6. What safety precautions should you observe when operating a planer?

Safety is paramount when operating a planer:

- Personal Protective Equipment (PPE): Wear appropriate PPE, including hard hat, safety glasses, earplugs, and high-visibility clothing.

- Site Safety: Ensure the work area is clear of hazards and has adequate ventilation.

- Machine Familiarization: Thoroughly familiarize yourself with the planer’s controls, safety features, and operating procedures.

- Inspection and Maintenance: Perform regular inspections and maintenance to ensure the planer is in proper working order.

- Planing Techniques: Follow safe planing techniques, avoiding excessive force or overloading the machine.

7. How do you maintain and troubleshoot a planer?

Maintenance:

Regular maintenance ensures optimal performance and longevity:

- Daily Inspections: Check fluid levels, belts, chains, cutting tools, and overall condition.

- Scheduled Maintenance: Follow the manufacturer’s recommendations for lubrication, filter changes, and other maintenance tasks.

- Cutting Tool Replacement: Replace worn or damaged cutting tools promptly to maintain cutting efficiency.

Troubleshooting:

Common planer issues and troubleshooting steps:

- Stalling: Check for overloading, dull cutting tools, or mechanical problems.

- Uneven Surface: Adjust the cutting depth and angle, check for worn or damaged cutting tools, or inspect the subgrade for irregularities.

- Excessive Vibration: Balance the cutting drum, inspect belts and chains for wear, or check for loose components.

8. What are the factors that affect the performance of a planer?

Planer performance is influenced by several factors:

- Material Hardness: Harder materials, such as concrete, require slower speeds and finer cutting tools.

- Cutting Depth: Deeper cuts require more power and may affect the planer’s speed and feed rate.

- Machine Capacity: The size and power of the planer determine its cutting capabilities and efficiency.

- Operator Skill: Experienced operators can adjust planer settings and techniques to optimize performance.

- Environmental Conditions: Extreme temperatures or moisture can affect the planer’s operation and cutting effectiveness.

9. How do you plan and prepare for a planing project?

Proper planning and preparation are crucial for a successful planing project:

- Site Assessment: Evaluate the existing pavement condition, traffic patterns, and work area requirements.

- Equipment Selection: Choose the appropriate planer based on the project specifications and material to be removed.

- Traffic Management: Develop a traffic control plan to ensure safety and minimize disruption during the project.

- Site Preparation: Clear the work area of obstacles, establish access points, and provide adequate lighting.

- Utility Coordination: Identify and protect any underground utilities that may be affected by the planing operation.

10. What are your strategies for minimizing dust and noise during planing operations?

Minimizing dust and noise during planing is essential for environmental protection and worker safety:

- Water Suppression: Use water spray to control dust and reduce noise levels.

- Enclosed Cab: Planers with enclosed cabs provide operators with a dust-free and quieter environment.

- Dust Collectors: Attach dust collectors to the planer to capture and filter dust particles.

- Scheduling: Plan operations during off-peak hours or in areas with less traffic to minimize noise impact.

- Community Communication: Inform nearby residents and businesses about the project and potential noise and dust.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Planer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Planer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Planer Operator, you will be entrusted with a wide range of responsibilities:

1. Machine Operation and Maintenance

You will be responsible for the smooth and efficient operation of the planer, ensuring that it is properly calibrated and maintained to produce high-quality products.

- Set up and operate the planer according to specifications

- Monitor machine performance and make necessary adjustments

- Perform regular maintenance and troubleshooting

2. Material Handling and Quality Control

You will be responsible for handling and inspecting materials, ensuring that they meet the required specifications:

- Inspect raw materials for defects and proper dimensions

- Load and unload materials onto the planer

- Monitor the planing process to identify defects

3. Safety and Compliance

You will be responsible for maintaining a safe and compliant work environment:

- Follow all safety protocols and procedures

- Maintain a clean and organized work area

- Comply with environmental regulations

4. Teamwork and Collaboration

You will work as part of a team, effectively coordinating with other operators and supervisors:

- Communicate effectively with colleagues

- Provide assistance and support to others when needed

- Maintain a positive and collaborative work atmosphere

Interview Tips

To ace your interview for the Planer Operator position, here are some tips and hacks:

1. Research the Company and the Role

Demonstrate your interest and knowledge of the company by researching its history, industry reputation, and project portfolio. Understanding the specific role and its responsibilities will help you tailor your responses to the interviewer’s questions.

2. Highlight Your Skills and Experience

Emphasize your technical skills and experience in planer operation, material handling, and quality control. Quantify your achievements and provide specific examples to support your claims.

3. Showcase Your Safety Consciousness

Safety is a crucial aspect of a Planer Operator role. Emphasize your commitment to safety by discussing your understanding of safety protocols and any relevant certifications or training you have.

4. Practice Common Interview Questions

Prepare for common interview questions by anticipating potential questions and practicing your responses. Consider questions related to your experience, technical skills, teamwork abilities, and safety awareness.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions that delve deeper into the role, company culture, or growth opportunities.

6. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive on time for your interview to convey your respect for the opportunity and the interviewer’s time.

7. Follow Up and Thank the Interviewer

After the interview, follow up with a thank-you note reiterating your interest in the position and how your skills and experience align with the company’s needs.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Planer Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!