Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rubber Turner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

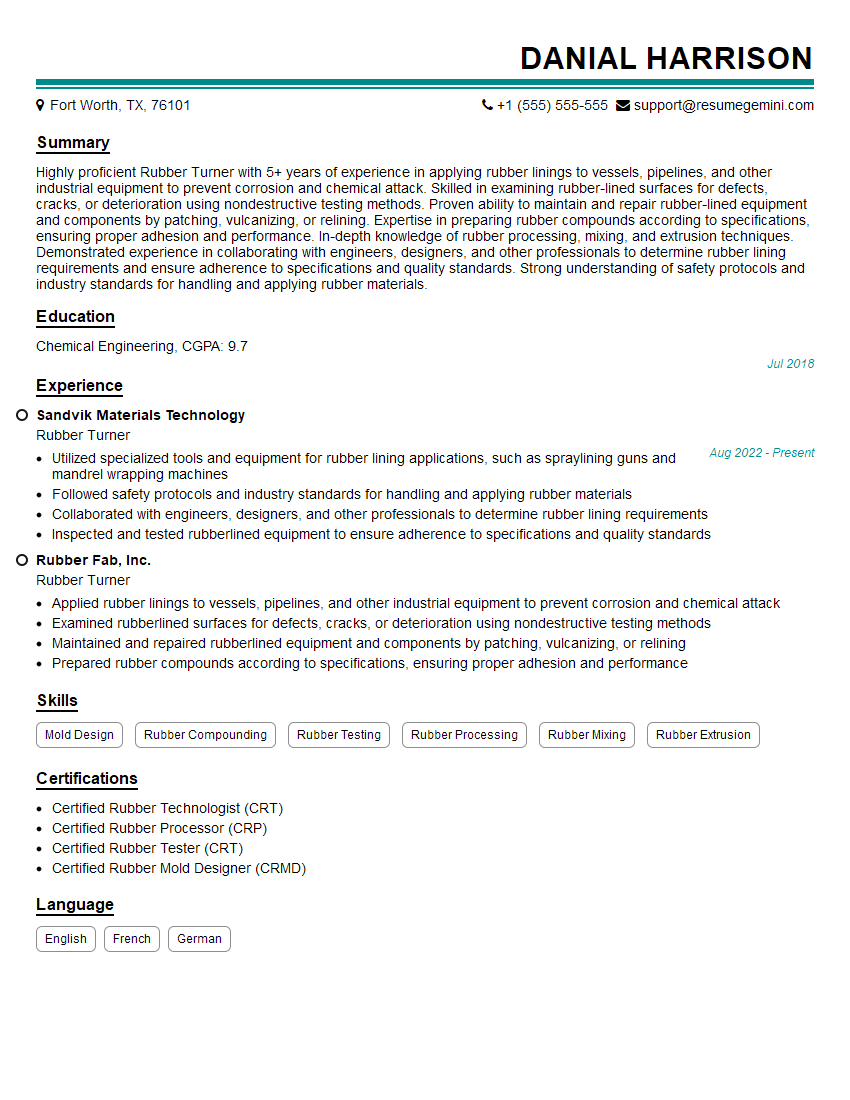

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Turner

1. What are your responsibilities as a Rubber Turner?

As a Rubber Turner, my primary responsibilities are to:

- Operate and control rubber turning machines to manufacture a variety of rubber products, such as O-rings, seals, and gaskets

- Set up and adjust the machine according to the desired product specifications

2. What types of rubber compounds have you worked with?

Natural Rubber

- Good elasticity and resilience

- Resistant to abrasion and tearing

Synthetic Rubber

- Oil and heat resistant

- Resistant to acids and alkalis

Specialty Rubbers

- Fluorosilicone rubber: Resistant to high temperatures and chemicals

- EPDM rubber: Weather and ozone resistant

3. Describe different toolings used in rubber turning?

The toolings used in rubber turning vary depending on the product being manufactured:

- Arbors and mandrels: Hold the rubber blank during turning

- Turning tools: Cut and shape the rubber

- Knurling tools: Create a textured surface

- Grooving tools: Create grooves or channels

4. What quality control procedures do you follow during rubber turning?

Quality control procedures:

- Visual inspection of the raw material before turning

- Dimensional checks of the finished product

- Hardness and elasticity testing

- Leak testing for seals and gaskets

5. How do you troubleshoot common problems that arise during rubber turning?

Common problems and troubleshooting:

- Uneven or rough surface: Incorrect tooling or worn-out tooling

- Undersized or oversized product: Incorrect machine settings

- Cracking or tearing: Overheating or using the wrong rubber compound

6. What safety precautions are necessary while operating a rubber turning machine?

Safety precautions:

- Wear proper safety gear, including gloves, eye protection, and a respirator

- Keep the machine area clean and free of debris

- Follow the manufacturer’s instructions for the safe operation of the machine

7. What is your experience with different types of rubber turning lathes?

Experience with different types of rubber turning lathes:

- Horizontal lathes

- Vertical lathes

- CNC lathes

8. How do you ensure the accuracy of the turned rubber products?

Maintaining accuracy:

- Calibrating the machine regularly

- Using precision tooling

- Following strict measurement procedures

9. What techniques do you use to improve the efficiency of the rubber turning process?

Improving efficiency:

- Optimizing machine settings

- Using sharp tooling

- Automating certain tasks

10. Describe the challenges you have faced as a Rubber Turner and how you overcame them.

Challenges and solutions:

- Meeting tight deadlines: Implemented lean manufacturing techniques to streamline the process

- Producing complex rubber parts: Upgraded to a CNC lathe for increased precision and efficiency

- Maintaining high quality standards: Implemented a rigorous quality control system

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Rubber Turner, you will play a pivotal role in the production of rubber products. Your primary responsibility will be to operate and maintain rubber-turning machinery to transform raw rubber into various shapes and sizes.

1. Equipment Operation

You will be entrusted with the safe and efficient operation of a range of rubber-turning machines, including lathes, milling machines, and grinders.

- Set up and calibrate machines according to specifications.

- Load and unload raw rubber materials and finished products.

- Monitor machine performance and make necessary adjustments to ensure optimal output.

2. Quality Control

Maintaining the quality of rubber products is of utmost importance.

- Inspect rubber products for defects and ensure compliance with quality standards.

- Identify potential quality issues and take corrective action.

- Document and report any quality deviations.

3. Maintenance and Repair

Ensuring the smooth operation of machinery is essential for efficient production.

- Perform routine maintenance tasks, such as cleaning, lubrication, and adjustment.

- Identify and troubleshoot mechanical issues.

- Coordinate with maintenance personnel for major repairs or upgrades.

4. Safety and Compliance

Maintaining a safe and compliant work environment is non-negotiable.

- Follow established safety protocols and wear appropriate protective gear.

- Comply with all environmental regulations related to rubber processing.

- Report any safety concerns or potential hazards.

Interview Tips

To ace your interview for a Rubber Turner position, preparation is key.

1. Research the Company and Industry

Demonstrating your knowledge of the company and the rubber industry will impress the interviewer.

- Visit the company website to learn about their products, services, and mission.

- Research industry trends and advancements in rubber technology.

2. Highlight Relevant Experience and Skills

Emphasize your experience operating rubber-turning machinery and your understanding of rubber processing.

- Quantify your accomplishments, using specific metrics to demonstrate your impact.

- Showcase your proficiency in quality control, maintenance, and safety procedures.

3. Be Enthusiastic and Professional

Convey your passion for the rubber industry and your eagerness to contribute to the company’s success.

- Dress professionally and maintain a positive attitude throughout the interview.

- Ask thoughtful questions to demonstrate your engagement and curiosity.

4. Prepare for Common Interview Questions

Anticipating and preparing for common interview questions will boost your confidence.

- Tell me about your experience in rubber processing.

- How do you ensure the quality of rubber products?

- Describe your approach to troubleshooting machinery issues.

- How do you prioritize safety in the workplace?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rubber Turner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!