Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Screw Machine Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

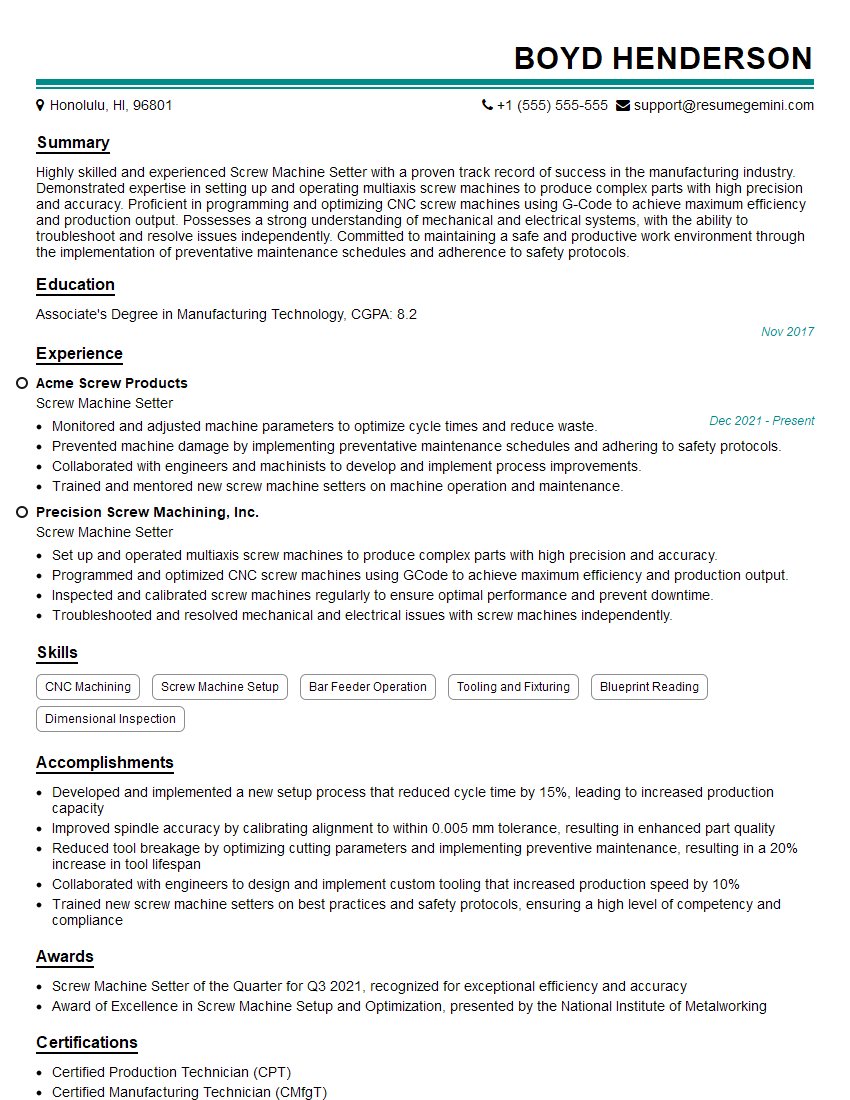

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screw Machine Setter

1. How would you troubleshoot a machine that is not producing parts to the correct specifications?

- Check the machine’s settings to ensure that they are correct for the part being produced.

- Inspect the tooling for wear or damage, and replace as needed.

- Check the material being used to ensure that it meets the required specifications.

- Calibrate the machine to ensure that it is operating accurately.

- Contact the machine manufacturer for technical support.

2. What are the most common types of screw machines and what are their advantages and disadvantages?

Single-spindle screw machines

- Advantages: Simple to operate, relatively inexpensive, can produce a wide variety of parts.

- Disadvantages: Slow production rates, limited to small parts.

Multi-spindle screw machines

- Advantages: Fast production rates, can produce complex parts, can be automated.

- Disadvantages: Complex to operate, expensive, limited to certain types of parts.

CNC screw machines

- Advantages: Extremely accurate, can produce complex parts, can be automated.

- Disadvantages: Expensive, complex to operate, require specialized training.

3. What are the different types of tooling used on screw machines and what are their applications?

- Cutting tools: Used to cut the material into the desired shape.

- Forming tools: Used to form the material into the desired shape.

- Knurling tools: Used to create a knurled surface on the material.

- Threading tools: Used to create threads on the material.

- Boring tools: Used to create holes in the material.

- Reaming tools: Used to enlarge holes in the material.

4. How do you adjust the speed and feed rates of a screw machine?

- Speed: The speed of the spindle is adjusted to control the cutting speed.

- Feed: The feed rate is adjusted to control the rate at which the cutting tool moves into the material.

5. What are the safety precautions that must be taken when operating a screw machine?

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Keep the work area clean and free of debris.

- Never operate the machine when it is not properly guarded.

- Be aware of the location of the emergency stop button.

- Follow all manufacturer’s instructions for safe operation.

6. How do you maintain a screw machine to ensure optimal performance?

- Clean the machine regularly to remove chips and debris.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine regularly for wear or damage, and repair or replace as needed.

- Calibrate the machine regularly to ensure that it is operating accurately.

7. What are the different types of materials that can be machined on a screw machine?

- Metals: Steel, aluminum, brass, copper, titanium

- Plastics: ABS, polycarbonate, nylon, PVC

- Wood

8. What are the different types of finishes that can be applied to parts produced on a screw machine?

- Plating: Electroplating, electroless plating, anodizing

- Painting

- Powder coating

- Heat treating

9. What are the different types of quality control checks that can be performed on parts produced on a screw machine?

- Visual inspection

- Dimensional inspection

- Functional testing

10. What are the different types of troubleshooting that can be performed on a screw machine?

- Mechanical troubleshooting

- Electrical troubleshooting

- Software troubleshooting

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screw Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screw Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Screw Machine Setter is responsible for setting up and operating screw machines to produce a variety of parts. The primary duties of a Screw Machine Setter include:

1. Machine Setup

Sets up and adjusts screw machines according to blueprints and specifications. Installs and aligns cutting tools, fixtures, and other attachments.

- Determines appropriate cutting speeds, feeds, and depths of cut.

- Inspects and maintains equipment to ensure proper operation.

2. Machine Operation

Monitors the operation of screw machines and makes adjustments as needed. Loads and unloads workpieces from the machine.

- Identifies and corrects any problems that may arise during operation.

- Maintains a clean and organized work area.

3. Quality Control

Inspects finished products to ensure that they meet quality standards. Uses measuring tools and gauges to verify dimensions and tolerances.

- Identifies and corrects any defects that are found.

- Maintains records of inspection data.

4. Troubleshooting

Troubleshoots and repairs problems with screw machines. Identifies the cause of the problem and takes corrective action.

- Works with other maintenance personnel to resolve complex issues.

- Keeps records of repairs and maintenance performed.

Interview Tips

To ace your interview for a Screw Machine Setter position, it is important to prepare thoroughly. Here are some tips to help you stand out:

1. Research the Company and the Position

Take the time to learn about the company’s history, products, and services. Research the specific Screw Machine Setter position you are applying for. This will help you understand the company’s needs and how your skills and experience can benefit them.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends.

2. Practice your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. Practice answering these questions clearly and concisely. Highlight your skills and experience that are most relevant to the position. Some common interview questions include:

- Tell me about your experience operating screw machines.

- What are your strengths and weaknesses as a Screw Machine Setter?

- How do you handle working under pressure?

- What are your salary expectations?

3. Be Prepared to Talk About Your Safety Experience

Safety is a top priority in any manufacturing environment. In your interview, be prepared to talk about your safety experience and how you would ensure a safe work environment. Highlight any safety training or certifications you have.

- Describe your experience with lockout/tagout procedures.

- What are your thoughts on the importance of wearing personal protective equipment?

4. Be Enthusiastic and Professional

First impressions matter. When you arrive for your interview, be sure to dress professionally and arrive on time. Be enthusiastic and respectful of the interviewer’s time. Thank the interviewer for their time and consideration.

- Make eye contact and smile when you greet the interviewer.

- Be prepared to answer questions about your experience and qualifications.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Screw Machine Setter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Screw Machine Setter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.