Are you gearing up for a career in Spar Cap Beveler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Spar Cap Beveler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

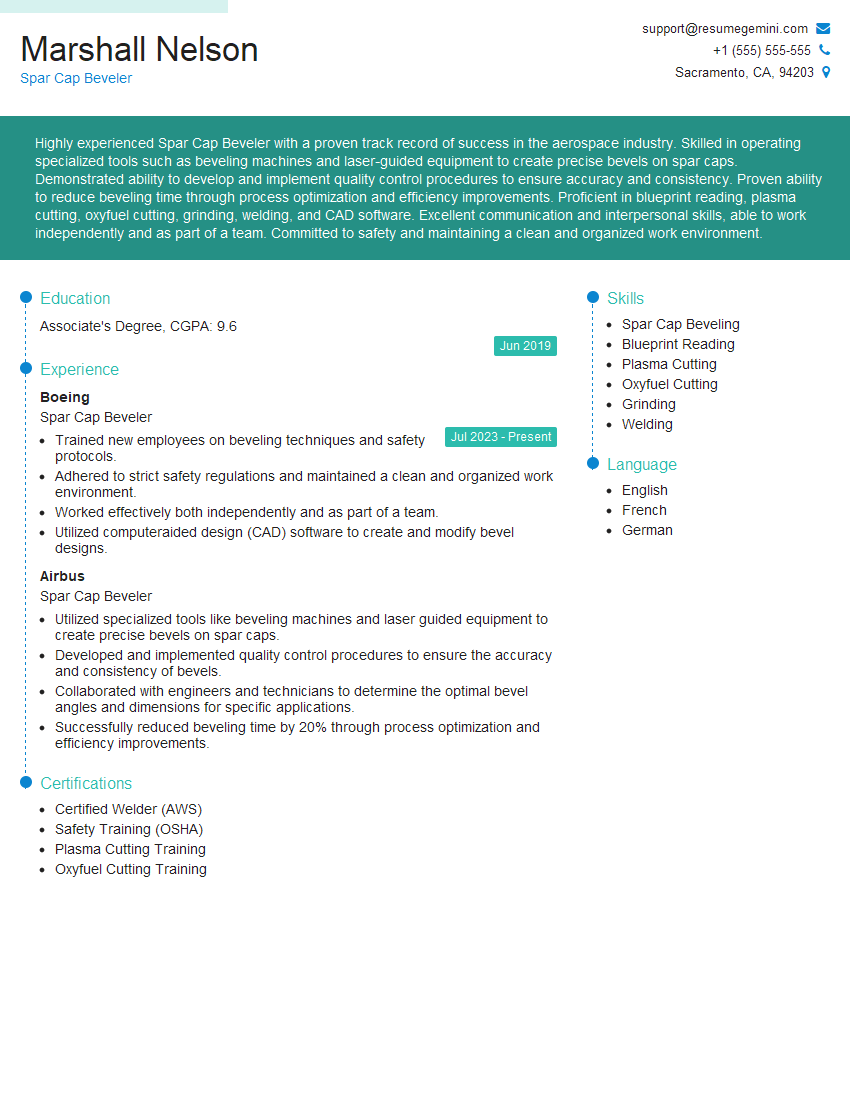

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spar Cap Beveler

1. What is a Spar Cap Beveler?

- A Spar Cap Beveler is a specialized machine used for the precise beveling of spar caps, which are the main structural components of aircraft wings.

- It ensures a smooth and accurate transition between the spar cap and the wing skin, creating a strong and aerodynamic bond.

2. How does a Spar Cap Beveler work?

Types of Spar Cap Bevelers

- Fixed Blade Beveler: Employs a fixed blade to cut the bevel, resulting in a consistent angle throughout the spar cap.

- Adjustable Blade Beveler: Allows for adjustments to the blade angle, enabling the creation of bevels with varying angles.

Operation

- The Spar Cap Beveler is mounted on a gantry or a track system positioned over the spar cap.

- The blade is guided along the spar cap’s surface, rotating to create a beveled edge.

- The beveling parameters, such as angle and depth, are precisely controlled to ensure the required specifications.

3. What are the key considerations when selecting a Spar Cap Beveler?

- Material Type: The type of material being beveled (e.g., aluminum, composite).

- Required Bevel Angle and Depth: The specific angle and depth of the bevel required.

- Accuracy and Precision: The level of accuracy and precision required for the beveling operation.

- Automation Capabilities: The need for automated or semi-automated beveling processes.

- Integration with Other Equipment: Compatibility with existing or planned manufacturing equipment.

4. What are the potential challenges faced when using a Spar Cap Beveler?

- Ensuring Accuracy: Maintaining precise and consistent bevel angles and depths.

- Minimizing Burr Formation: Controlling the cutting process to minimize burrs or sharp edges.

- Dealing with Variation in Materials: Adapting to variations in material properties and thicknesses.

- Safety Precautions: Implementing proper safety measures to prevent injuries and accidents.

- Integration and Maintenance: Seamless integration with other manufacturing systems and regular maintenance.

5. How do you ensure the quality of bevels produced using a Spar Cap Beveler?

- Establishing Quality Standards: Defining clear quality standards for the bevels.

- Regular Inspections: Conducting regular inspections throughout the beveling process.

- Calibration and Maintenance: Calibrating and maintaining the Spar Cap Beveler to ensure accuracy and precision.

- Operator Training: Providing training to operators on the proper use and maintenance of the machine.

- Quality Control Measures: Implementing quality control measures to monitor and improve the beveling process.

6. What are the emerging trends in Spar Cap Beveler technology?

- Automation: Increased automation of beveling processes to improve efficiency and productivity.

- Digitalization: Integration of digital technologies to enhance precision and data monitoring.

- Advanced Beveling Techniques: Development of new beveling techniques to accommodate complex and lightweight materials.

- Sustainability: Focus on eco-friendly and sustainable beveling practices.

- Cloud-based Solutions: Leveraging cloud-based platforms for data storage and remote monitoring.

7. What are the advantages of using a Spar Cap Beveler?

- Precision and Accuracy: Ensures precise and accurate bevels, reducing the risk of structural defects.

- Efficiency: Automates the beveling process, increasing productivity and reducing labor costs.

- Consistency: Maintains consistent bevel angles and depths, ensuring a uniform bond between the spar cap and wing skin.

- Reduced Waste: Minimizes material waste by optimizing the beveling process.

- Improved Safety: Eliminates the need for manual beveling, reducing the risk of injuries.

8. Describe a situation where you faced a challenge or made an improvement while using a Spar Cap Beveler.

- Challenge: Encountered a variance in material thickness that affected the bevel angle.

- Improvement: Implemented an adaptive control system to automatically adjust the bevel angle based on material thickness.

- Outcome: Improved bevel quality and reduced the risk of structural defects.

9. What are the different types of Spar Cap Bevelers available in the market?

- Standard Spar Cap Beveler: Designed for general-purpose beveling of spar caps.

- Heavy-Duty Spar Cap Beveler: Suitable for thick and heavy spar caps.

- CNC (Computer Numerical Control) Spar Cap Beveler: Offers precise and automated beveling.

- Portable Spar Cap Beveler: Designed for use in remote or confined areas.

- Custom Spar Cap Bevelers: Tailored to specific beveling requirements and material types.

10. How do you maintain and calibrate a Spar Cap Beveler?

- Regular Inspection: Regularly inspect all components for wear and damage.

- Blade Sharpening: Sharpen the blade as per manufacturer’s recommendations.

- Lubrication: Lubricate all moving parts to ensure smooth operation.

- Calibration: Calibrate the Spar Cap Beveler to ensure accuracy and precision using standard reference materials.

- Documentation: Maintain detailed records of maintenance and calibration procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spar Cap Beveler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spar Cap Beveler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spar Cap Bevelers are highly skilled professionals in the manufacturing industry. They are responsible for beveling the edges of spar caps, which are the main structural components of aircraft wings. This process requires a high level of precision and attention to detail.

1. Preparing Spar Caps for Beveling

Before beveling spar caps, they need to be properly prepared. This involves cleaning the surface of the cap, marking the area to be beveled, and setting up the beveling machine.

- Clean the surface of the spar cap using a solvent or degreaser.

- Mark the area to be beveled using a scribe or chalk line.

- Set up the beveling machine according to the manufacturer’s instructions.

2. Beveling the Spar Caps

Once the spar caps are prepared, they can be beveled. This is done using a beveling machine, which is a specialized tool that grinds the edges of the cap to a specific angle.

- Position the spar cap in the beveling machine.

- Select the desired bevel angle.

- Start the beveling process and slowly guide the cap through the machine.

3. Inspecting the Beveled Spar Caps

After the spar caps have been beveled, they need to be inspected to ensure that they meet the required specifications. This involves checking the bevel angle, the surface finish, and the overall dimensions of the cap.

- Check the bevel angle using a protractor.

- Inspect the surface finish of the cap for any defects.

- Measure the overall dimensions of the cap to ensure that they meet the specifications.

4. Maintaining the Beveling Equipment

Spar Cap Bevelers are also responsible for maintaining the beveling equipment. This involves cleaning and lubricating the machine, as well as replacing worn parts.

- Clean the beveling machine regularly using a solvent or degreaser.

- Lubricate the moving parts of the machine according to the manufacturer’s instructions.

- Replace worn parts as needed.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are some tips for acing your Spar Cap Beveler interview:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, its values, and its goals. It will also help you tailor your answers to the specific requirements of the job.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked. Practice answering these questions in advance so that you can deliver confident and well-thought-out responses. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Be Prepared to Talk About Your Experience

The interviewer will likely want to know about your experience in the field. Be prepared to talk about your skills, your knowledge, and your accomplishments. Use specific examples to illustrate your points and highlight your qualifications for the job.

4. Ask Questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company, the position, and the interviewer. Asking thoughtful questions shows that you are engaged and interested in the job.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Spar Cap Beveler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Spar Cap Beveler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.