Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Spinning Lathe Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Spinning Lathe Operator so you can tailor your answers to impress potential employers.

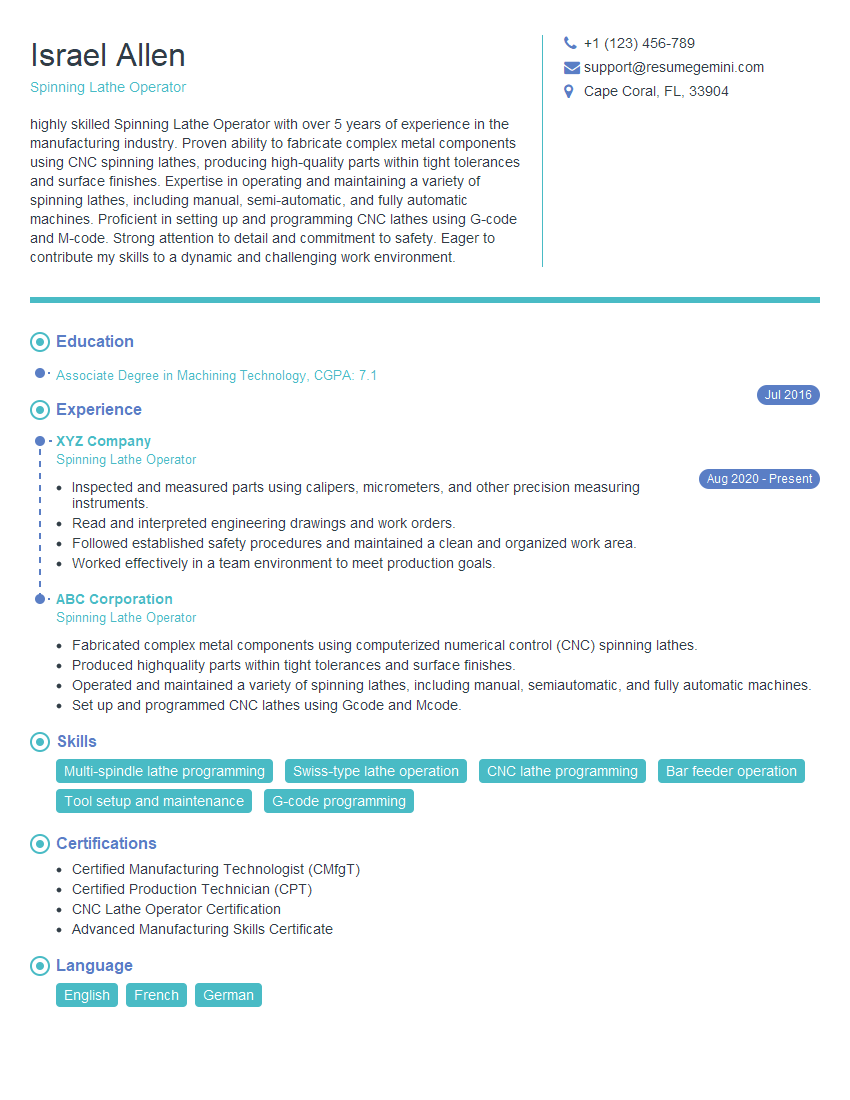

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spinning Lathe Operator

1. What are the different types of spinning lathes?

There are two main types of spinning lathes: manual and CNC, manual spinning lathes are operated by hand while CNC spinning lathes are computer-controlled.

- Manual spinning lathes

- CNC spinning lathes

2. What are the different types of spinning operations?

Embossing

- Raising the metal to form a design or shape

- Using a blunt tool to press the metal into a die

Necking

- Reducing the diameter of the metal

- Using a roller to press the metal against a mandrel

Flanging

- Creating a flange or rim on the edge of the metal

- Using a roller to press the metal against a form

3. What are the different types of materials that can be spun?

A variety of materials can be spun, including metals, plastics, and composites, some of the most common materials used in spinning are:

- Aluminum

- Steel

- Copper

- Brass

- Titanium

4. What are the different factors that affect the quality of a spun part?

The quality of a spun part is affected by a number of factors, including:

- The type of material being spun

- The thickness of the material

- The speed of the lathe

- The pressure applied to the metal

- The skill of the operator

5. What are the different applications of spinning?

Spinning is used in a wide variety of applications, including:

- Automotive

- Aerospace

- Medical

- Lighting

- Appliance

6. What are the different safety precautions that must be taken when operating a spinning lathe?

When operating a spinning lathe, it is important to take the following safety precautions:

- Wear appropriate safety gear, including eye protection, gloves, and a lab coat

- Keep the work area clean and free of debris

- Be aware of the location of the emergency stop button

- Never operate the lathe while under the influence of alcohol or drugs

7. What is the difference between spinning and deep drawing?

Spinning and deep drawing are two metalworking processes that are used to create parts with complex shapes, spinning is a process in which a flat sheet of metal is formed over a rotating mandrel, deep drawing is a process in which a flat sheet of metal is drawn into a die to create a part with a desired shape.

- Spinning is a more versatile process than deep drawing

- Spinning can be used to create parts with more complex shapes than deep drawing

- Deep drawing is a faster process than spinning

- Deep drawing is a more cost-effective process than spinning

8. What is the difference between roll spinning and shear spinning?

Roll spinning and shear spinning are two types of spinning processes, roll spinning is a process in which a roller is used to press the metal against a mandrel, shear spinning is a process in which a shear is used to cut the metal as it is being formed.

- Roll spinning is a more common process than shear spinning

- Roll spinning is a faster process than shear spinning

- Shear spinning can be used to create parts with more complex shapes than roll spinning

- Shear spinning is a more expensive process than roll spinning

9. What are the different types of mandrels used in spinning?

There are a variety of different types of mandrels used in spinning, the type of mandrel used will depend on the shape of the part being formed.

- Solid mandrels – Solid mandrels are made of a single piece of metal

- Expanding mandrels – Expanding mandrels can be expanded or contracted to fit the shape of the part being formed

- Collapsible mandrels – Collapsible mandrels can be collapsed to remove them from the part after it has been formed

10. What are the different types of tools used in spinning?

There are a variety of different types of tools used in spinning, the type of tool used will depend on the operation being performed.

- Forming tools – Forming tools are used to shape the metal

- Cutting tools – Cutting tools are used to cut the metal

- Finishing tools – Finishing tools are used to smooth the surface of the metal

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spinning Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spinning Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spinning Lathe Operators are responsible for a variety of tasks in a manufacturing environment. Some of their key responsibilities include:1. Operating Spinning Lathes

Spinning Lathe Operators are skilled in operating spinning lathes, which are used to create metal parts by spinning them at high speeds and applying pressure to shape the metal.

- Set up and operate spinning lathes to create metal parts

- Control the speed and pressure of the lathe to achieve the desired shape

2. Preparing and Inspecting Materials

Spinning Lathe Operators must prepare and inspect the materials they use to ensure that they are of the correct quality and size.

- Prepare and inspect metal sheets and other materials for spinning

- Check the dimensions and quality of the materials to ensure they meet specifications

3. Maintaining Equipment

Spinning Lathe Operators are responsible for maintaining the equipment they use, including lathes, tools, and other machinery.

- Clean and lubricate lathes and other equipment regularly

- Inspect equipment for wear and tear and make necessary repairs

4. Following Safety Procedures

Spinning Lathe Operators must follow all safety procedures to ensure their safety and the safety of others.

- Wear appropriate safety clothing and equipment

- Follow established safety procedures when operating lathes and other equipment

Interview Tips

To ace an interview for a Spinning Lathe Operator position, it is important to prepare thoroughly and showcase your skills and experience. Here are some interview tips to help you succeed:1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media profiles

- Read industry news and articles about the company

2. Practice Your Answers to Common Questions

There are some common questions that are often asked in interviews for Spinning Lathe Operator positions. By practicing your answers to these questions, you can increase your confidence and deliver clear and concise responses.

- Tell me about your experience operating spinning lathes

- How do you prepare and inspect materials for spinning?

- What are your safety procedures when operating lathes and other equipment?

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the position. Emphasize your ability to operate spinning lathes, prepare and inspect materials, and maintain equipment.

- Use specific examples to illustrate your skills and experience

- Quantify your accomplishments whenever possible

4. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position, and to assess whether the position is a good fit for you.

- Ask about the company’s culture and values

- Ask about the company’s plans for growth and expansion

- Ask about the company’s commitment to safety

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spinning Lathe Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.