Are you gearing up for a career in Swiss-Type Screw Machine Set-Up Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Swiss-Type Screw Machine Set-Up Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

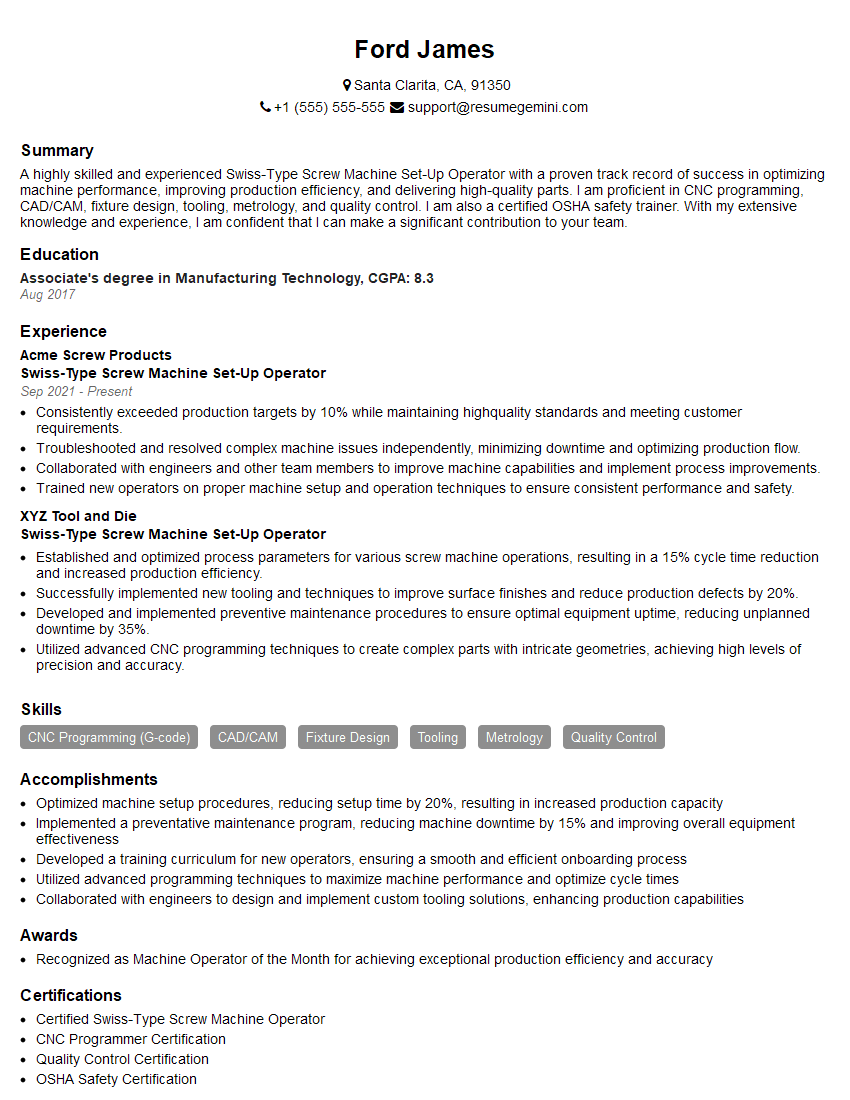

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Swiss-Type Screw Machine Set-Up Operator

1. Describe the key responsibilities of a Swiss-Type Screw Machine Set-Up Operator?

- Set up and operate Swiss-type screw machines to produce precision components.

- Interpret engineering drawings and specifications to determine tooling, feeds, and speeds.

- Adjust and calibrate machines to ensure accuracy and repeatability.

- Monitor machines during operation to identify and correct any issues.

- Perform preventive maintenance and troubleshooting to minimize downtime.

2. Explain the steps involved in setting up a Swiss-type screw machine?

Tooling Selection:

- Select appropriate cutting tools and holders based on part geometry and material.

- Properly mount and align tools to ensure precision and accuracy.

Program Setup:

- Enter program codes to define machine movements, feeds, and speeds.

- Optimize program for efficiency and minimize cycle time.

Machine Setup:

- Set up collets or chucks to hold the workpiece securely.

- Calibrate axes, spindle speeds, and feed rates.

- Test run the program to verify accuracy and correct any discrepancies.

3. What are the common types of Swiss-type screw machines?

- Cam-operated machines: Use cams to control machine movements.

- CNC (Computer Numerical Control) machines: Use computer-controlled programs to operate.

- CNC Swiss-type lathes: Combine the precision of Swiss-type machines with the flexibility of CNC control.

4. How do you ensure part quality when operating a Swiss-type screw machine?

- Inspect raw materials to verify dimensions and tolerances.

- Continuously monitor machine performance and adjust as needed.

- Conduct periodic part inspections to identify any deviations from specifications.

- Implement quality control procedures to prevent and correct defects.

5. Describe the types of materials typically processed on Swiss-type screw machines?

- Metals: Steel, stainless steel, aluminum, brass, exotic alloys.

- Plastics: Nylon, Delrin, PEEK, PTFE.

- Other materials: Wood, ceramics, composites.

6. How do you optimize cycle time on a Swiss-type screw machine?

- Review and streamline the program code.

- Increase feed rates and spindle speeds within the machine’s capabilities.

- Minimize tool changes and setup times.

- Use high-performance cutting tools.

7. Explain how to troubleshoot common problems encountered when operating a Swiss-type screw machine?

- Tool breakage: Inspect tools for damage, check toolholder alignment.

- Part defects: Verify program parameters, check material quality.

- Machine malfunctions: Refer to maintenance manuals, contact manufacturer for support.

- System errors: Reset the machine, check electrical connections.

8. What are the safety precautions to observe when operating a Swiss-type screw machine?

- Wear appropriate safety gear (glasses, gloves, hearing protection).

- Ensure proper guarding of machine components.

- Follow lock-out/tag-out procedures for machine maintenance.

- Avoid contact with moving parts.

- Keep work area clean and organized.

9. How do you maintain and calibrate a Swiss-type screw machine?

- Perform regular cleaning and lubrication.

- Inspect and replace worn or damaged parts.

- Calibrate axes, spindle, and sensors using precision measuring instruments.

- Follow manufacturer’s maintenance schedule.

10. Describe the industry standards and best practices related to Swiss-type screw machine operation?

- Adhere to ISO 9001 quality management system.

- Follow American National Standards Institute (ANSI) and other industry standards.

- Stay updated with emerging technologies and best practices.

- Attend industry workshops and seminars for continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Swiss-Type Screw Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Swiss-Type Screw Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Swiss-Type Screw Machine Set-Up Operator plays a crucial role in the manufacturing process, ensuring the efficient operation and optimal performance of Swiss-type screw machines. Their key responsibilities encompass:

1. Machine Setup and Preparation

• Setting up and calibrating Swiss-type screw machines according to specifications and blueprints.

• Installing and adjusting cutting tools, fixtures, and workholding devices.

• Testing and verifying machine setup for accuracy and functionality.

2. Program Creation and Optimization

• Creating and modifying CNC (Computer Numerical Control) programs based on engineering drawings.

• Optimizing CNC programs for efficiency, reduced cycle times, and improved part quality.

• Troubleshooting and resolving CNC program errors.

3. Tooling and Maintenance

• Selecting and installing appropriate cutting tools and accessories for specific machining operations.

• Monitoring tool wear and performance, performing necessary adjustments and replacements.

• Maintaining and servicing Swiss-type screw machines, including lubrication, cleaning, and minor repairs.

4. Quality Control and Inspection

• Inspecting finished parts to ensure they meet quality standards and specifications.

• Using precision measuring instruments and techniques to verify dimensions, tolerances, and surface finishes.

• Maintaining records of inspection results and identifying areas for improvement.

5. Production Monitoring and Optimization

• Monitoring machine performance and production output to identify bottlenecks and inefficiencies.

• Implementing process improvements to increase productivity and reduce waste.

• Working with other team members to ensure smooth production flow and minimize downtime.

Interview Tips

To excel in a Swiss-Type Screw Machine Set-Up Operator interview, candidates should prepare thoroughly and demonstrate their technical skills, experience, and problem-solving abilities.

1. Research the Company and Industry

• Learn about the company’s products, services, and reputation in the industry.

• Research the current trends and advancements in Swiss-type screw machine technology.

2. Practice Your Technical Skills

• Review your knowledge of CNC programming, machine setup, and tooling.

• Be prepared to discuss your experience in troubleshooting CNC programs and resolving machine issues.

3. Highlight Your Problem-Solving Abilities

• Provide examples of how you have identified and resolved problems in previous roles.

• Emphasize your analytical and critical thinking skills.

4. Showcase Your Attention to Detail

• Discuss your commitment to quality and accuracy in your work.

• Explain how you ensure that finished parts meet or exceed specifications.

5. Be Enthusiastic and Punctual

• Express your passion for working with Swiss-type screw machines and manufacturing.

• Arrive on time for your interview and dress professionally.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Swiss-Type Screw Machine Set-Up Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Swiss-Type Screw Machine Set-Up Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.