Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tool Lathe Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

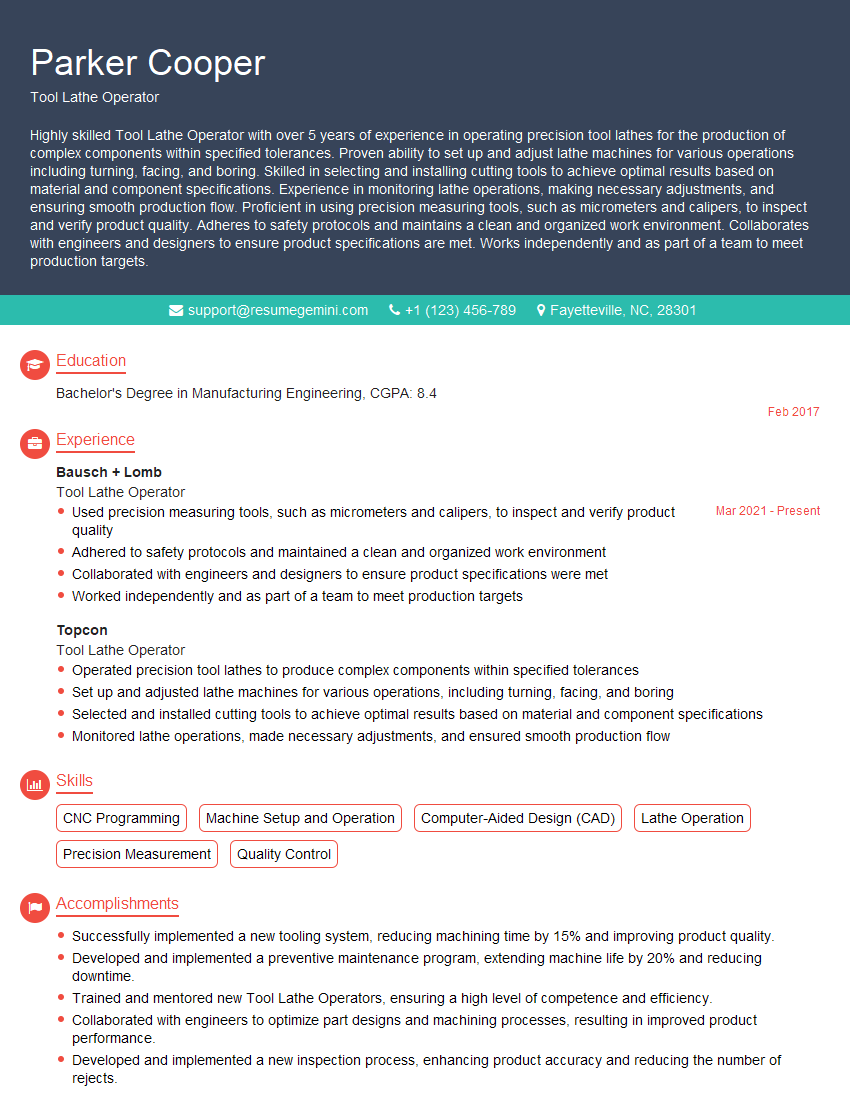

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Lathe Operator

1. What are the different types of lathes and their applications?

There are different types of lathes, each with its own specific applications. Some of the most common types include:

- Engine lathes: These are the most versatile type of lathe and can be used for a wide variety of tasks, such as turning, facing, boring, and threading.

- Turret lathes: These lathes have a turret that holds multiple tools, which allows for quick and easy tool changes. They are often used for production work, where high volumes of parts need to be produced.

- CNC lathes: These lathes are controlled by a computer, which allows for precise and repeatable operation. They are often used for complex parts that require high levels of accuracy.

2. What are the different types of cutting tools used in lathe operations?

Cutting Tools

- Turning tools

- Facing tools

- Boring tools

- Threading tools

- Knurling tools

Factors

- Type of material being cut

- Desired surface finish

- Accuracy and precision required

3. What are the different types of workholding devices used in lathe operations?

The type of workholding device used in lathe operations depends on the size, shape, and material of the workpiece. Some of the most common types of workholding devices include:

- Chucks: Chucks are used to hold cylindrical workpieces. They come in a variety of sizes and types, and can be either manual or automatic.

- Collets: Collets are used to hold small, round workpieces. They are typically used in conjunction with a collet chuck.

- Centers: Centers are used to support long, slender workpieces. They are typically used in conjunction with a chuck or collet.

- Vise: Vises are used to hold irregularly shaped workpieces. They can be either manual or automatic.

4. What are the different types of cutting fluids used in lathe operations?

Cutting fluids are used to lubricate the cutting tool and workpiece, and to help remove chips. There are three main types of cutting fluids:

- Water-soluble cutting fluids: These cutting fluids are made up of water and a soluble oil. They are the most common type of cutting fluid used in lathe operations.

- Oil-based cutting fluids: These cutting fluids are made up of mineral oil and a variety of additives. They are often used for heavy-duty cutting operations.

- Synthetic cutting fluids: These cutting fluids are made up of synthetic oils and a variety of additives. They are often used for high-performance cutting operations.

5. What are the different types of feeds and speeds used in lathe operations?

The feed rate is the rate at which the cutting tool moves into the workpiece. The speed is the rate at which the workpiece rotates. The correct feed rate and speed are essential for achieving a good surface finish and preventing damage to the cutting tool or workpiece.

- Feed rate: The feed rate is typically measured in inches per minute (ipm) or millimeters per minute (mm/min).

- Speed: The speed is typically measured in revolutions per minute (rpm).

6. What are the different types of tolerances that can be achieved in lathe operations?

The tolerance is the amount of variation that is allowed in a dimension. Tolerance limits may be: Unilateral, Bilateral, Equal Bilateral. The tolerance is typically specified in thousandths of an inch (0.001″) or thousandths of a millimeter (0.001 mm).

- Commercial tolerance: This is the loosest tolerance and is typically used for non-critical dimensions.

- Precision tolerance: This is a tighter tolerance and is typically used for critical dimensions.

- Ultra-precision tolerance: This is the tightest tolerance and is typically used for very critical dimensions.

7. What are the different types of finishes that can be achieved in lathe operations?

The finish is the surface texture of the workpiece. The finish is typically specified in microinches (µin) or micrometers (µm). There are a variety of different finishes that can be achieved, including:

- Rough finish: This is the roughest finish and is typically used for non-critical parts.

- Medium finish: This is a smoother finish and is typically used for parts that will be painted or plated.

- Fine finish: This is the smoothest finish and is typically used for parts that will be used in critical applications.

8. What are the different types of safety precautions that should be taken when operating a lathe?

- Wear appropriate safety gear, including safety glasses, gloves, and a lab coat.

- Keep the work area clean and free of debris.

- Inspect the lathe and cutting tools before each use.

- Secure the workpiece properly before starting the lathe.

- Never reach over or around the rotating workpiece.

- Stop the lathe before making any adjustments.

- Be aware of the location of the emergency stop button.

9. What are the different types of maintenance procedures that should be performed on a lathe?

- Clean the lathe regularly.

- Lubricate the lathe according to the manufacturer’s instructions.

- Inspect the lathe for wear and tear on a regular basis.

- Calibrate the lathe regularly.

10. What are the different types of troubleshooting procedures that can be performed on a lathe?

Troubleshooting procedures can vary depending on the specific issue you are experiencing. However, some general troubleshooting tips include:

- Check the power supply.

- Check the fuses.

- Check the belts and pulleys.

- Check the cutting tool.

- Check the workpiece.

- Check the coolant.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Lathe Operators are skilled machinists who use lathes to create precision parts and components. Their primary responsibilities include:

1. Machine Operation

Operating and maintaining lathes to create parts according to specifications

- Selecting and installing appropriate tooling and fixtures

- Loading and unloading workpieces

2. Quality Control

Inspecting and measuring parts to ensure they meet quality standards

- Using precision measuring instruments

- Reporting defects and initiating corrective actions

3. Machine Maintenance

Performing basic maintenance on lathes to ensure optimal performance

- Cleaning and lubricating machines

- Changing worn parts

4. Safety Compliance

Adhering to all safety regulations and procedures

- Wearing appropriate safety gear

- Following established work practices

Interview Tips

To prepare for an interview for a Tool Lathe Operator position, candidates should consider the following tips:

1. Research the Company and Role

Research the company and the specific role to gain a deep understanding of their business and the requirements of the position.

- Review the company website, LinkedIn page, and industry publications.

- Identify the key skills and experience required for the role.

2. Practice Answering Common Interview Questions

Practice answering common interview questions related to your skills, experience, and motivation.

- Prepare examples of your work experience that demonstrate your abilities in machine operation, quality control, and safety compliance.

- Explain your reasons for wanting the job and how your skills align with the company’s needs.

3. Highlight Your Technical Skills

Emphasize your technical skills and experience with lathes and other machining equipment.

- Describe your knowledge of different types of lathes, tooling, and cutting techniques.

- Quantify your accomplishments, such as the number of parts produced or the accuracy achieved in machining operations.

4. Demonstrate Your Safety Awareness

Demonstrate your strong safety awareness and understanding of industry best practices.

- Describe your experience with safety protocols and procedures.

- Explain how you contribute to maintaining a safe work environment for yourself and others.

5. Prepare Questions for the Interviewer

Preparing questions for the interviewer indicates your interest in the role and the company.

- Ask about the company’s growth plans or the specific projects you would be involved in.

- Inquire about opportunities for professional development or training.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tool Lathe Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.