Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tool Turret Lathe Set-Up Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

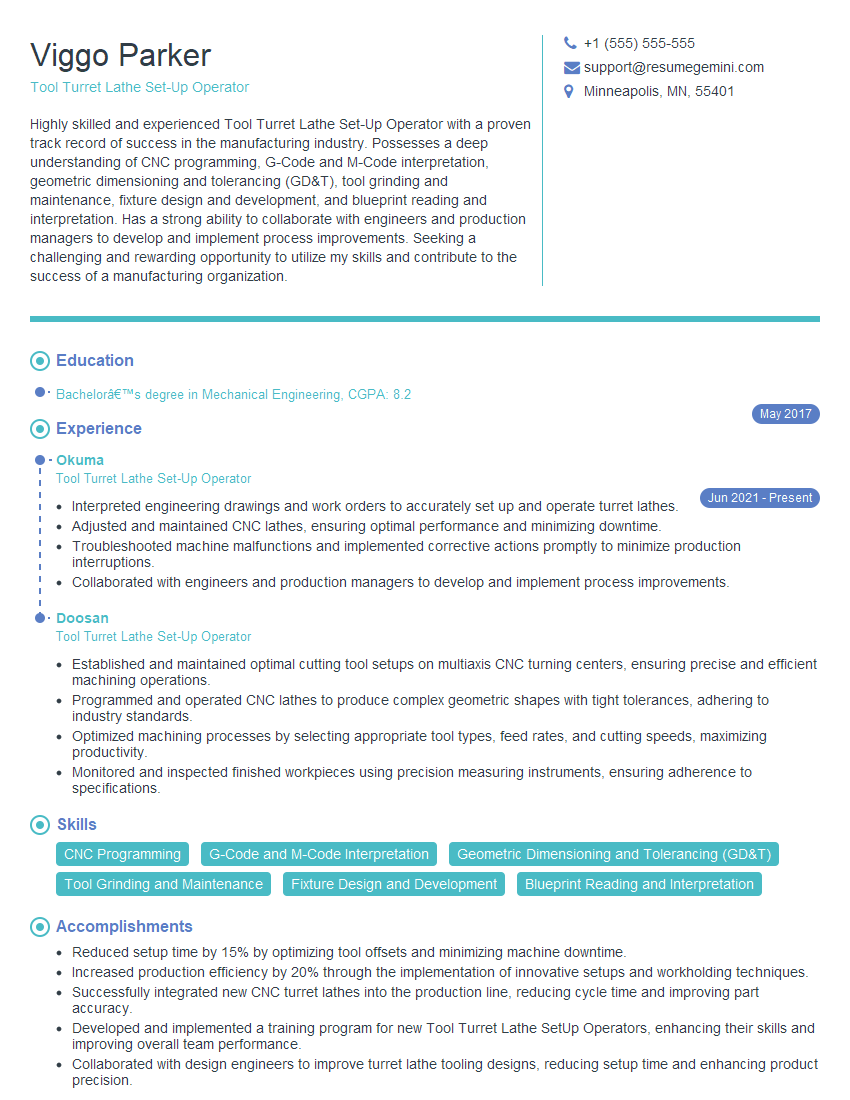

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Turret Lathe Set-Up Operator

1. What are the key responsibilities of a Tool Turret Lathe Set-Up Operator?

- Set up and operate tool turret lathes to produce precision parts

- Interpret blueprints and work orders to determine machining requirements

- Select and install cutting tools and accessories

- Align and adjust the machine to ensure accurate cuts

- Monitor the machining process and make adjustments as needed

- Inspect finished parts to ensure they meet specifications

- Maintain and troubleshoot lathes and other equipment

- Follow safety protocols and maintain a clean and organized work area

2. What are the different types of tool turret lathes?

CNC Lathes

- Computer Numerical Control (CNC) lathes are automated machines that use computer programs to control the cutting process.

- CNC lathes offer high precision and repeatability, and can produce complex parts quickly and efficiently.

Manual Lathes

- Manual lathes are operated by hand, and require the operator to control all aspects of the cutting process.

- Manual lathes are less precise than CNC lathes, but offer greater flexibility and can be used to produce one-of-a-kind parts.

3. What are the different types of cutting tools used on a tool turret lathe?

- Turning tools: Used to shape the outside diameter of a workpiece

- Facing tools: Used to create flat surfaces on a workpiece

- Boring tools: Used to create holes in a workpiece

- Grooving tools: Used to create grooves or slots in a workpiece

- Threading tools: Used to create threads on a workpiece

4. What are the safety precautions that must be followed when operating a tool turret lathe?

- Always wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Never reach into the machine while it is running.

- Keep the work area clean and free of debris.

- Be aware of the location of the emergency stop button.

- Follow all manufacturer’s instructions for safe operation of the machine.

5. What are the different types of materials that can be machined on a tool turret lathe?

- Metals: Steel, aluminum, brass, copper, etc.

- Plastics: ABS, polycarbonate, nylon, etc.

- Wood

- Ceramics

6. What are the different types of finishes that can be achieved on a tool turret lathe?

- Rough finish: A surface that has been machined with a coarse cutting tool, leaving visible tool marks.

- Semi-finish: A surface that has been machined with a finer cutting tool, leaving fewer visible tool marks.

- Finish: A surface that has been machined with a very fine cutting tool, leaving a smooth and polished surface.

7. What are the different types of tolerances that can be achieved on a tool turret lathe?

- Tight tolerance: A tolerance of ±0.0005 inches or less.

- Medium tolerance: A tolerance of ±0.001 inches to ±0.005 inches.

- Loose tolerance: A tolerance of ±0.005 inches or more.

8. What are the different types of measuring tools used on a tool turret lathe?

- Calipers: Used to measure the outside diameter, inside diameter, and depth of a workpiece.

- Micrometers: Used to measure the thickness of a workpiece.

- Dial indicators: Used to measure the runout of a workpiece.

- Height gauges: Used to measure the height of a workpiece.

- Levels: Used to ensure that the lathe is level.

9. How do you troubleshoot a tool turret lathe?

- Identify the problem.

- Check the power supply.

- Check the hydraulic system.

- Check the cutting tools.

- Check the workpiece.

- Refer to the manufacturer’s instructions.

10. How do you maintain a tool turret lathe?

- Clean the machine regularly.

- Lubricate the machine regularly.

- Inspect the machine regularly for wear and tear.

- Calibrate the machine regularly.

- Follow the manufacturer’s instructions for maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Turret Lathe Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Turret Lathe Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Turret Lathe Set-Up Operators are responsible for setting up, operating, and maintaining tool turret lathes. They also perform various tasks related to the operation of the lathe, such as loading and unloading materials, and monitoring the progress of the machining process.

1. Set up and operate tool turret lathes

Tool Turret Lathe Set-Up Operators are responsible for setting up and operating tool turret lathes. This involves:

- Selecting the appropriate tools and setting them up on the lathe.

- Positioning the workpiece on the lathe and securing it in place.

- Programming the lathe to perform the desired machining operations.

- Starting and monitoring the machining process.

2. Maintain tool turret lathes

In addition to setting up and operating tool turret lathes, Set-Up Operators are also responsible for maintaining them. This involves:

- Cleaning and lubricating the lathe.

- Inspecting the lathe for wear and tear.

- Replacing worn or damaged parts.

3. Load and unload materials

Set-Up Operators are also responsible for loading and unloading materials into and out of the lathe. This involves:

- Loading the raw material into the lathe.

- Unloading the finished product from the lathe.

4. Monitor the progress of the machining process

Set-Up Operators are responsible for monitoring the progress of the machining process. This involves:

- Watching the lathe to ensure that it is operating properly.

- Checking the workpiece to ensure that it is being machined to the correct specifications.

Interview Tips

Here are some tips to help you ace your interview for a Tool Turret Lathe Set-Up Operator position:

1. Research the company

Before you go to your interview, take some time to research the company. This will help you understand the company’s culture, values, and goals. You should also be familiar with the company’s products or services.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Tool Turret Lathe Set-Up Operator. Be prepared to talk about your responsibilities, your accomplishments, and your skills.

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic and positive about the position. Be sure to show your interest in the position and the company. Also, be positive about your abilities and your potential to contribute to the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool Turret Lathe Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!