Are you gearing up for a career in Tumble Tailstock Turret Lathe Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tumble Tailstock Turret Lathe Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

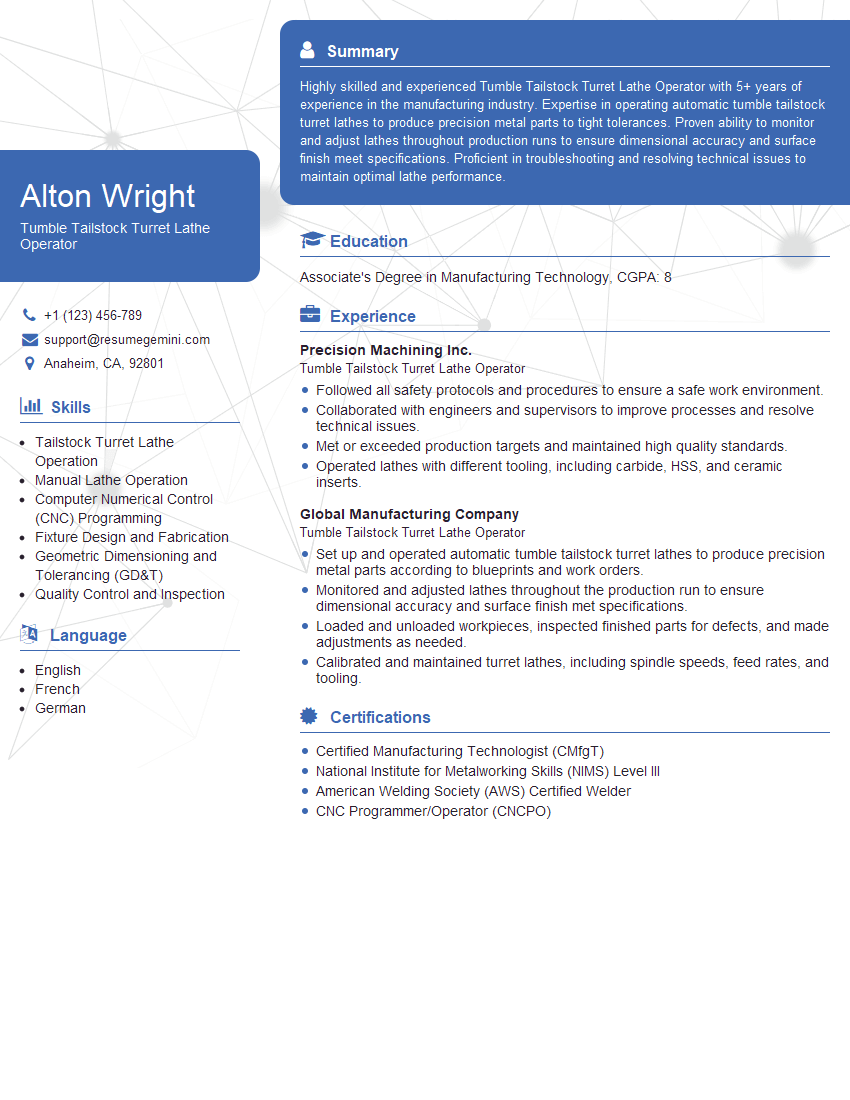

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tumble Tailstock Turret Lathe Operator

1. Explain the process of setting up a Tumble Tailstock Turret Lathe for a specific job?

Answer:

- Review the job specifications and gather necessary tools and materials.

- Mount the workpiece on the chuck or fixture securely.

- Install the appropriate tooling in the turret and adjust its position.

- Set the feed rate, cutting speed, and depth of cut according to the material and desired finish.

- Align the tailstock and adjust its position to support the workpiece.

- Conduct a test run and make necessary adjustments to ensure accuracy and efficiency.

2. How do you handle complex geometries and tight tolerances on a Tumble Tailstock Turret Lathe?

Answer:

1: Precision Measurement and Tool Selection

- Utilizing precision measuring tools such as calipers, micrometers, and dial indicators to ensure accurate dimensions.

- Selecting the appropriate cutting tools with the correct geometry and sharpness.

Subheading 2: Skilled Operation and Attention to Detail

- Operating the lathe with precision and control to achieve tight tolerances.

- Paying meticulous attention to detail throughout the machining process.

3. How do you maintain and troubleshoot a Tumble Tailstock Turret Lathe?

Answer:

- Regularly cleaning and lubricating the lathe to prevent wear and extend its lifespan.

- Inspecting and replacing worn or damaged parts to maintain accuracy and safety.

- Diagnosing and resolving issues by identifying potential causes and applying appropriate solutions.

4. Explain the different types of cutting tools used on a Tumble Tailstock Turret Lathe and their applications?

Answer:

- Turning Tools: Used for facing, boring, grooving, and contouring operations.

- Drilling Tools: Used for creating holes of various diameters and depths.

- Thread Cutting Tools: Used for cutting internal and external threads.

- Boring Bars: Used for enlarging or finishing holes.

5. What are the safety precautions that should be taken when operating a Tumble Tailstock Turret Lathe?

Answer:

- Always wear appropriate safety gear (gloves, eye protection, ear protection).

- Never operate the lathe without proper training and authorization.

- Ensure that all guards and shields are in place and functional.

- Keep the work area clean and free of debris.

- Follow emergency procedures in case of an accident or malfunction.

6. Explain the role of coolant in Tumble Tailstock Turret Lathe operations?

Answer:

- Lubrication: Reduces friction and heat between the cutting tool and the workpiece.

- Cooling: Dissipates heat generated during the cutting process.

- Chip Removal: Flushes away metal chips from the cutting zone.

- Workpiece Protection: Prevents workpiece distortion or damage due to excessive heat.

7. How do you ensure quality control and accuracy when operating a Tumble Tailstock Turret Lathe?

Answer:

- Precision Measurement: Using accurate measuring tools and techniques.

- Calibration and Maintenance: Ensuring that the lathe is properly calibrated and maintained.

- Tool Inspection: Checking cutting tools for wear and sharpness.

- First Article Inspection: Inspecting the first produced part to ensure it meets specifications.

- In-Process Inspection: Conducting inspections throughout the production process.

8. Describe the different types of materials that can be machined on a Tumble Tailstock Turret Lathe?

Answer:

- Metals: Steel, aluminum, brass, copper, titanium.

- Plastics: ABS, polycarbonate, PVC, acrylic.

- Wood: Hardwoods, softwoods, plywood.

- Ceramics: Porcelain, alumina, zirconia.

9. What is the difference between a tumble tailstock and a fixed tailstock?

Answer:

- Tumble Tailstock: Can be rotated and positioned along the lathe bed, allowing for machining of angled or tapered surfaces.

- Fixed Tailstock: Remains stationary, providing support for the workpiece during machining operations.

10. How do you handle and prevent chatter when operating a Tumble Tailstock Turret Lathe?

Answer:

- Proper Tool Sharpness: Ensuring that cutting tools are sharp and free of nicks.

- Optimal Cutting Conditions: Setting appropriate feed rates and cutting speeds to minimize vibration.

- Workpiece Support: Using appropriate fixtures and supports to stabilize the workpiece.

- Damping Devices: Employing vibration dampers or shock absorbers to reduce chatter.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tumble Tailstock Turret Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tumble Tailstock Turret Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tumble Tailstock Turret Lathe Operator is responsible for operating a tumble tailstock turret lathe to produce precision parts. This lathe is a versatile machine that can perform a variety of operations, including turning, drilling, boring, and milling.

1. Machine Operation

The operator must be able to set up and operate the lathe correctly, ensuring that the machine is running at the proper speed and feed rates. They must also be able to monitor the machine during operation to detect any problems.

- Set up and operate the lathe to produce precision parts.

- Monitor the machine during operation to detect any problems.

2. Tooling and Setup

The operator must be able to select the appropriate tooling for the job and install it on the lathe. They must also be able to set up the lathe for the desired operation, including setting the speed, feed, and depth of cut.

- Select the appropriate tooling for the job and install it on the lathe.

- Set up the lathe for the desired operation, including setting the speed, feed, and depth of cut.

3. Part Inspection

The operator must be able to inspect the parts produced by the lathe to ensure that they meet the required specifications. They must be able to use measuring tools to check the dimensions and finish of the parts.

- Inspect the parts produced by the lathe to ensure that they meet the required specifications.

- Use measuring tools to check the dimensions and finish of the parts.

4. Maintenance

The operator must be able to perform basic maintenance on the lathe, including cleaning and lubrication. They must also be able to identify any problems with the lathe and report them to maintenance personnel.

- Perform basic maintenance on the lathe, including cleaning and lubrication.

- Identify any problems with the lathe and report them to maintenance personnel.

Interview Tips

Preparing for an interview for a Tumble Tailstock Turret Lathe Operator position can help you showcase your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company

Before the interview, take some time to research the company. This will help you understand the company’s culture, values, and products. You can also learn about the company’s history, its competitors, and its financial performance.

- Visit the company’s website.

- Read news articles about the company.

- Talk to people who work for the company.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview. You can practice answering questions with a friend or family member.

- What are your strengths and weaknesses?

- Why are you interested in this position?

- What is your experience with tumble tailstock turret lathes?

3. Dress Professionally

First impressions matter, so make sure to dress professionally for the interview. This means wearing a suit or business dress that is clean and pressed. You should also make sure your shoes are polished and your hair is neat.

- Wear a suit or business dress.

- Make sure your clothes are clean and pressed.

- Polish your shoes.

- Make sure your hair is neat.

4. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be confident and honest, and the interviewer will be able to see your potential.

- Be yourself.

- Be confident and honest.

- Let the interviewer get to know the real you.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tumble Tailstock Turret Lathe Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!