Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Broaching Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Broaching Machine Operator so you can tailor your answers to impress potential employers.

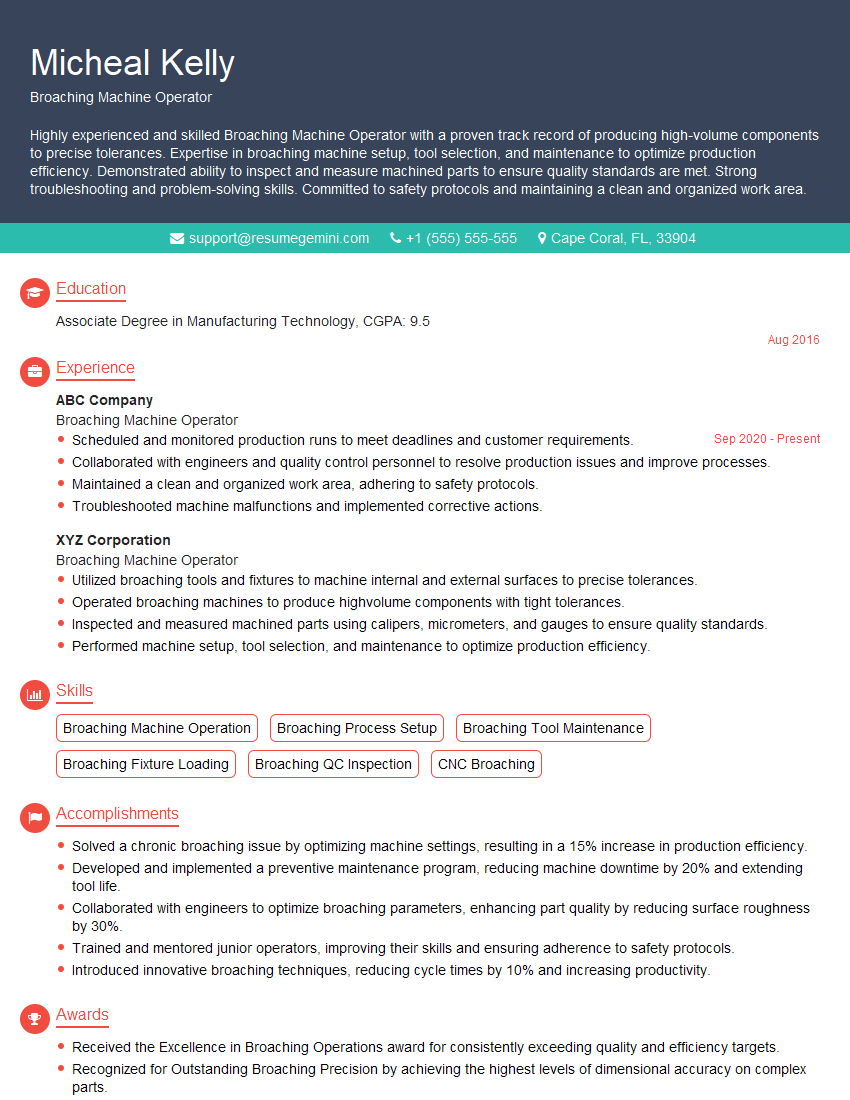

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Broaching Machine Operator

1. What are different types of Broaching?

There are 3 main types of Broaching:

- Horizontal Broaching

- Vertical Broaching

- Surface Broaching

2. What is the Broaching speed and feed?

Cutting Speed:

- Cast iron – 7.6 – 12.7 m/min

- Steel – 5.1- 10.2 m/min

- Brass – 15.2 – 17.8 m/min

Feed Rate:

- Rough Broaching – 0.005 – 0.015 mm/stroke

- Finish Broaching – 0.002 – 0.008 mm/stroke

3. What are the important factors to consider before Broaching?

- Workpiece Material and its hardness

- Broaching Machine Capacity

- Broach design and the number of teeth

- Coolant and Lubrication

- Safety Measures

4. What are common problems faced during broaching?

- Tool Breakage

- Poor Surface Finish

- Chattering

- Overheating of the Tool and Workpiece

- Safety Hazards

5. How do you ensure the accuracy of Broaching?

- Proper Machine Setup

- Use of sharp tools

- Correct Feed and Speed Calculations

- Regular Maintenance of Broaching Machine

- Use of Jigs and Fixtures

6. How do you handle Broach sharpening?

- Identify the dull or damaged teeth

- Use appropriate sharpening equipment like a hand grinder or CNC grinder

- Maintain the proper grinding angle and clearance

- Check the sharpness using a comparator

- Lubricate and store the sharpened Broach properly

7. What is the difference between Internal and External Broaching?

- Internal Broaching: Used to create internal surfaces like holes, slots, and keyways.

- External Broaching: Used to create external surfaces like flat surfaces, profiles, and irregular shapes.

8. What are the safety precautions to be taken while operating Broaching Machine?

- Wear proper safety gear like gloves, eye protection, and earplugs

- Ensure the workpiece is securely clamped

- Keep the work area clean and free from obstructions

- Be aware of the machine’s movements

- Follow all the operating instructions

9. How can you improve the efficiency of Broaching?

- Use of high-quality Broaches

- Optimizing Cutting Parameters

- Proper Work Holding Techniques

- Regular Maintenance

- Minimizing Setup Time

10. What are the latest advancements in Broaching Technology?

- CNC Broaching Machines

- High-Speed Broaching

- Use of Coated Broaches

- Broaching Simulation Software

- Advanced Broach Design Techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Broaching Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Broaching Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Broaching Machine Operator is responsible for operating and maintaining broaching machines, which are used to cut and shape metal. They must have a strong understanding of the principles of broaching and be able to operate the machine safely and efficiently.

1. Set up and operate broaching machines

This involves loading the workpiece into the machine, setting the cutting tools, and starting the machine cycle.

- Load and unload workpieces from the machine.

- Set up and adjust cutting tools.

- Monitor the machine cycle and make adjustments as needed.

2. Inspect and measure workpieces

This involves checking the dimensions and surface finish of the workpiece to ensure that it meets specifications.

- Inspect workpieces for defects.

- Measure workpieces to ensure they meet specifications.

- Make adjustments to the machine or cutting tools as needed.

3. Maintain and troubleshoot broaching machines

This involves cleaning and lubricating the machine, and identifying and fixing any problems that may occur.

- Clean and lubricate the machine.

- Identify and fix any problems with the machine.

- Order and install replacement parts.

4. Maintain a safe work area

This involves keeping the work area clean and free of hazards, and following all safety procedures.

- Keep the work area clean and free of hazards.

- Follow all safety procedures.

- Report any unsafe conditions or practices to the supervisor.

Interview Tips

To ace the interview for a Broaching Machine Operator position, it is important to be prepared and to have a clear understanding of the key job responsibilities. Here are some tips to help you prepare:

1. Research the company and the position

This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the position.

- Visit the company’s website and read about their history, mission, and products or services.

- Read the job description carefully and identify the key skills and qualifications that the employer is looking for.

2. Practice your answers to common interview questions

This will help you to feel confident and prepared during the interview.

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”.

- Practice your answers out loud so that you can deliver them clearly and concisely.

3. Be prepared to discuss your experience and skills

The interviewer will want to know about your experience operating broaching machines and your skills in setting up, operating, and maintaining them.

- Highlight your experience operating broaching machines, including the types of machines you have operated and the types of workpieces you have produced.

- Discuss your skills in setting up, operating, and maintaining broaching machines.

4. Be prepared to answer questions about safety

The interviewer will want to know about your safety procedures and your experience working in a safe environment.

- Describe your safety procedures when operating broaching machines.

- Discuss your experience working in a safe environment.

5. Be prepared to ask questions

Asking questions at the end of the interview shows that you are interested in the position and that you are taking the interview seriously.

- Prepare a few questions to ask the interviewer about the position, the company, and the work environment.

- Ask questions that show that you are interested in the position and that you are taking the interview seriously.

Next Step:

Now that you’re armed with the knowledge of Broaching Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Broaching Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini