Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Router Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

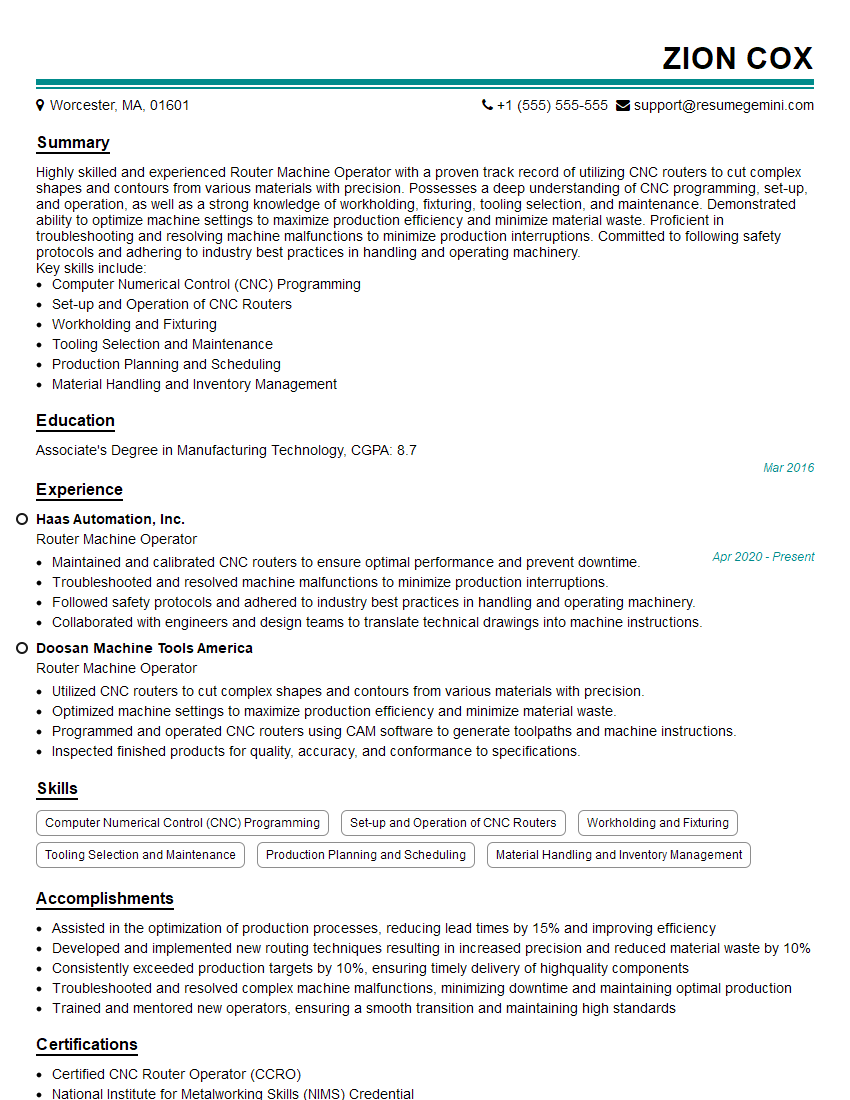

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Router Machine Operator

1. What are the different types of router machines and how do they operate?

A router machine is a type of woodworking machine that is used to cut and shape wood. There are three main types of router machines: plunge routers, fixed-base routers, and trim routers.

- Plunge routers are the most versatile type of router. They can be used to make a variety of cuts, including plunge cuts, dadoes, and mortises. Plunge routers have a motor that is mounted on a baseplate. The baseplate can be moved up and down to control the depth of the cut.

- Fixed-base routers are less versatile than plunge routers, but they are easier to use. Fixed-base routers have a motor that is mounted on a fixed baseplate. The depth of the cut is controlled by the height of the cutter.

- Trim routers are the smallest and lightest type of router. They are designed for light-duty applications, such as trimming laminate and veneer. Trim routers have a motor that is mounted on a small baseplate. The baseplate can be tilted to make angled cuts.

2. How do you set up and calibrate a router machine?

Getting Started:

- Secure the router to the table or workpiece using clamps.

- Install the appropriate bit for the job.

- Adjust the fence to the desired distance from the bit.

- Set the depth of cut using the depth stop.

Calibration:

- Use a test piece of material to make a test cut.

- Measure the depth of the cut and adjust the depth stop accordingly.

- Make a few additional test cuts to ensure that the router is set up correctly.

3. What are the different types of router bits and what are they used for?

There are many different types of router bits, each designed for a specific purpose. Some of the most common types of router bits include:

- Straight bits are used to make straight cuts.

- Rabbet bits are used to make rabbets, which are slots that are cut into the edge of a workpiece.

- Dado bits are used to make dadoes, which are wide slots that are cut into the surface of a workpiece.

- Mortise bits are used to make mortises, which are square or rectangular holes that are cut into the surface of a workpiece.

- Dovetail bits are used to make dovetails, which are interlocking joints that are used to connect two pieces of wood.

4. What are the safety precautions that must be taken when operating a router machine?

When operating a router machine, it is important to take the following safety precautions:

- Wear eye protection, ear protection, and a dust mask.

- Keep your hands away from the bit.

- Use a push stick or featherboard to guide the workpiece.

- Never operate the router while it is unattended.

- Unplug the router before making any adjustments.

5. How do you troubleshoot common problems with router machines?

There are a number of common problems that can occur with router machines, including:

- The router is not cutting smoothly. This can be caused by a dull bit, a loose fence, or a misaligned router.

- The router is making a burning smell. This can be caused by a dull bit, a too-fast feed rate, or a workpiece that is not properly secured.

- The router is making a chattering noise. This can be caused by a loose bit, a misaligned fence, or a workpiece that is not properly secured.

- The router is not turning on. This can be caused by a faulty power cord, a tripped circuit breaker, or a problem with the router’s motor.

6. What is the difference between a router and a shaper?

A router and a shaper are both woodworking machines that can be used to cut and shape wood. However, there are some key differences between the two machines.

- Routers are more versatile than shapers. They can be used to make a wider variety of cuts, including plunge cuts, dadoes, and mortises.

- Shapers are more powerful than routers. They are designed for heavy-duty applications, such as cutting large pieces of wood or making complex shapes.

- Routers are typically less expensive than shapers. They are a good option for hobbyists and woodworkers who are on a budget.

7. What are some tips for getting the best results from a router machine?

Here are some tips for getting the best results from a router machine:

- Use sharp bits.

- Use a push stick or featherboard to guide the workpiece.

- Feed the workpiece slowly and evenly.

- Keep the router moving constantly.

- Make test cuts before making the final cut.

8. What are some of the most common mistakes that router machine operators make?

Some of the most common mistakes that router machine operators make include:

- Using dull bits.

- Not using a push stick or featherboard to guide the workpiece.

- Feeding the workpiece too quickly or unevenly.

- Not keeping the router moving constantly.

- Not making test cuts before making the final cut.

9. What are some of the latest trends in router technology?

Some of the latest trends in router technology include:

- CNC routers: CNC routers are computer-controlled routers that can be used to create complex shapes and designs.

- Cordless routers: Cordless routers are powered by batteries, which gives them greater portability.

- Compact routers: Compact routers are smaller and lighter than traditional routers, making them easier to use for small projects.

10. What is your favorite type of router project to work on?

My favorite type of router project to work on is making furniture. I enjoy the challenge of creating something that is both beautiful and functional. I especially enjoy making pieces that have intricate details, such as dovetail joints or carved moldings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Router Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Router Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Router Machine Operators are experts when it comes to using a router machine. They are responsible for setting up, operating, and maintaining these machines to produce high-quality parts and products.

1. Machine Operation

Operators will set up the machine according to the specifications provided, which includes installing the appropriate cutting tools and fixtures.

- Interpret blueprints and technical drawings to understand the design and specifications of the parts to be produced.

- Select and install the correct cutting tools and fixtures for the job.

- Operate the machine to cut, shape, and finish materials such as wood, metal, plastic, or composites.

- Monitor the cutting process to ensure that the parts are being produced to the required specifications.

- Make adjustments to the machine or cutting tools as needed to maintain accuracy and efficiency.

2. Quality Control

Checking that the parts produced are within the required tolerances and specifications is also part of the job.

- Inspect the finished parts to ensure that they meet the required dimensions, tolerances, and surface finish.

- Use measuring tools and gauges to verify the accuracy of the parts.

- Identify and correct any defects or errors in the parts.

- Maintain a clean and organized work area to ensure the quality of the parts produced.

3. Machine Maintenance

Operators will often be responsible for maintaining their equipment to ensure it is in good working condition.

- Perform routine maintenance on the machine, such as lubrication, cleaning, and adjustments.

- Identify and troubleshoot any problems with the machine.

- Make minor repairs to the machine as needed.

- Keep a record of the maintenance performed on the machine.

4. Safety

Router Machine Operators must follow proper safety procedures to avoid injury, as the machines can be very dangerous.

- Wear appropriate safety gear, such as safety glasses, earplugs, and gloves.

- Follow all safety protocols and procedures.

- Operate the machine in a safe and responsible manner.

- Report any safety hazards or concerns to the supervisor.

Interview Tips

Interviews can be nerve-wracking, but there are some things you can do to prepare and increase your chances of success. Here are a few tips:

1. Research the Company

Before you go on an interview, it is very important to research the company. This will help you understand their culture, mission, and values which will help you determine if you are a good fit for the company.

- Visit the company’s website and social media pages.

- Read news articles and reviews about the company.

- Talk to people in your network who work or have worked for the company.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the actual interview.

- Think about your skills and experience and how they relate to the job requirements.

- Prepare examples of your work that demonstrate your qualifications.

- Practice your answers out loud or with a friend or family member.

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the company culture and the position you are applying for.

- Consider the company’s dress code and the industry you are applying to.

- Choose clothes that make you feel confident and comfortable.

- Make sure your clothes are clean and free of wrinkles or stains.

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Plan to arrive at the interview location 10-15 minutes early.

- Allow extra time for traffic or unexpected delays.

- If you are running late, call or email the interviewer to let them know.

- Arrive at the interview location with enough time to sign in and get settled.

5. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and authentic in your answers.

- Share your unique qualities and experiences.

- Be confident in your abilities and skills.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Router Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!