Feeling lost in a sea of interview questions? Landed that dream interview for Profiling Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Profiling Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

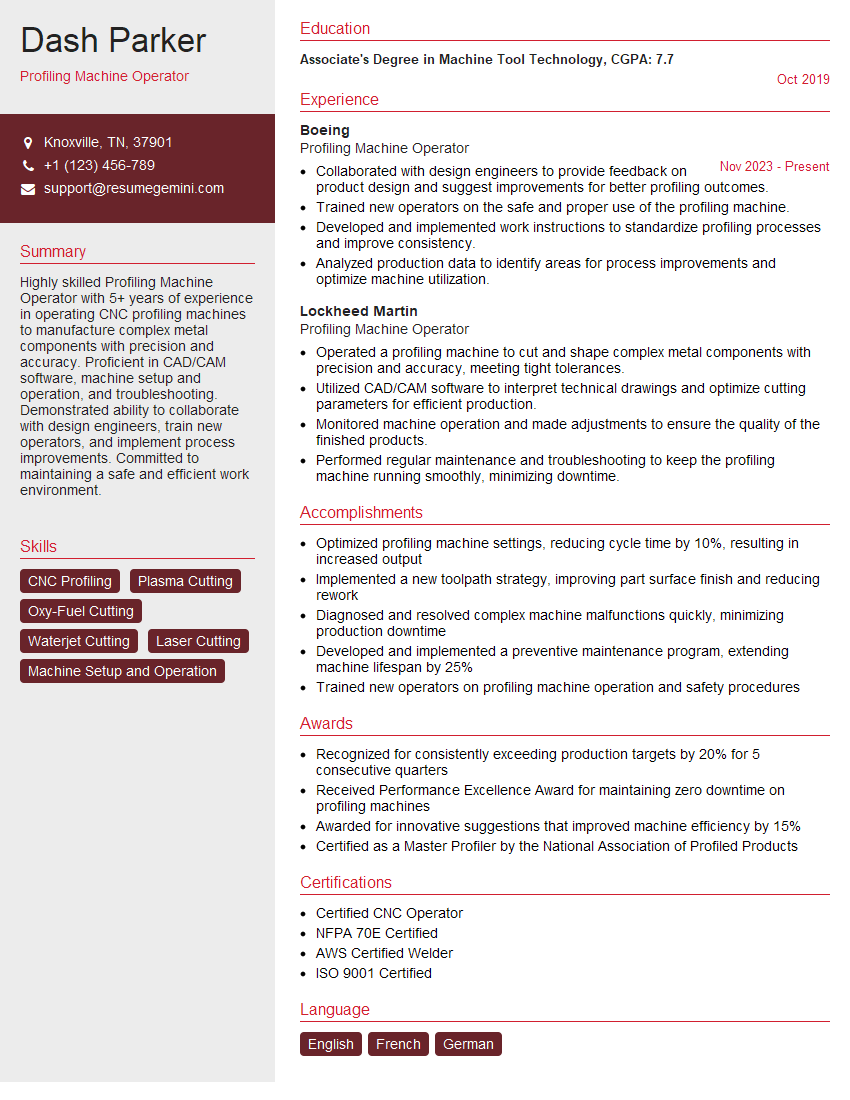

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Profiling Machine Operator

1. Describe the profiling process and explain the role of the Profiling Machine Operator?

The profiling process involves shaping and cutting metal pieces using a Profiling Machine. As a Profiling Machine Operator, my role is to:

- Set up and operate the Profiling Machine, ensuring precision and accuracy.

- Interpret technical drawings and convert them into machine instructions (G-code).

- Select and install appropriate cutting tools based on the material and design requirements.

2. What are the different types of Profiling Machines and their applications?

CNC Profiling Machines

- Computer Numerical Control (CNC) Profiling Machines provide high precision and automation.

- Used for complex and intricate cutting operations, such as in aerospace and automotive industries.

Plasma Profiling Machines

- Plasma Profiling Machines utilize ionized gas (plasma) to cut conductive materials.

- Capable of achieving high cutting speeds and narrow kerf widths.

Flame Profiling Machines

- Flame Profiling Machines use an oxy-fuel flame to cut metal sheets.

- Suitable for cutting thicker materials and simple shapes.

3. Explain the safety precautions to be taken while operating a Profiling Machine?

Ensuring safety is paramount when operating a Profiling Machine:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Secure the workpiece properly to prevent movement during cutting.

- Maintain a clean and organized work area free of debris and potential hazards.

- Follow established safety protocols and regularly inspect the machine for any issues.

4. What are the common challenges faced during Profiling operations and how do you overcome them?

Profiling operations can present various challenges:

- Material Distortion: Use appropriate cutting parameters, such as speed and feed rates, to minimize heat distortion.

- Tool Wear: Regularly inspect and replace cutting tools to maintain optimal performance and avoid defects.

- Machine Malfunctions: Quickly identify and troubleshoot machine issues to minimize downtime and ensure production efficiency.

5. How do you ensure the accuracy and quality of the profiled parts?

To guarantee accuracy and quality:

- Precisely follow technical drawings and machine instructions.

- Calibrate the Profiling Machine regularly and check for any deviations.

- Inspect profiled parts using measuring instruments and compare them to specifications.

6. What is the importance of maintenance and calibration for Profiling Machines?

Regular maintenance and calibration are crucial for Profiling Machines:

- Scheduled maintenance ensures optimal performance and extends machine lifespan.

- Calibration ensures accurate cuts and consistent quality of profiled parts.

- Proper maintenance minimizes downtime and prevents costly repairs.

7. How do you stay updated on the latest advancements in Profiling technology?

To stay current with the industry:

- Attend industry conferences and exhibitions to learn about new technologies.

- Read technical journals and articles to stay abreast of developments.

- Engage in discussions with colleagues and participate in training programs.

8. Describe your experience with different CAD/CAM software for Profiling operations.

In my previous role, I utilized:

- AutoCAD for creating and editing technical drawings.

- SolidWorks for 3D modeling and design verification.

- Mastercam for converting designs into G-code instructions for the Profiling Machine.

9. How do you handle working in a fast-paced production environment with tight deadlines?

In fast-paced environments:

- I prioritize tasks and plan my workload effectively.

- Communicate regularly with the team to coordinate and avoid delays.

- Stay focused and maintain a high level of accuracy to meet deadlines without compromising quality.

10. What are your strengths and weaknesses as a Profiling Machine Operator?

My strengths include:

- Strong technical skills and a deep understanding of Profiling operations.

- Experience in operating various Profiling Machines and CAD/CAM software.

- Attention to detail and commitment to producing high-quality parts.

As for weaknesses, I am always looking to expand my knowledge and improve my skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Profiling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Profiling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Profiling Machine Operators are responsible for operating and maintaining profiling machines to cut and shape metal components. They must have a strong understanding of the machine’s operation and be able to troubleshoot and resolve any issues that may arise.

1. Machine Operation

Profiling Machine Operators are responsible for setting up and operating profiling machines to cut and shape metal components. They must be able to read and interpret blueprints and drawings to ensure that the machine is set up correctly. They must also be able to operate the machine safely and efficiently to produce high-quality parts.

- Set up and operate profiling machines to cut and shape metal components.

- Read and interpret blueprints and drawings to ensure that the machine is set up correctly.

- Operate the machine safely and efficiently to produce high-quality parts.

2. Machine Maintenance

Profiling Machine Operators are responsible for maintaining and servicing profiling machines to ensure that they are operating properly. They must be able to identify and resolve any issues that may arise. They must also be able to perform regular maintenance tasks to keep the machine in good condition.

- Maintain and service profiling machines to ensure that they are operating properly.

- Identify and resolve any issues that may arise.

- Perform regular maintenance tasks to keep the machine in good condition.

3. Quality Control

Profiling Machine Operators are responsible for inspecting and testing metal components to ensure that they meet the required specifications. They must be able to identify any defects or inconsistencies and take corrective action to ensure that the components are of high quality.

- Inspect and test metal components to ensure that they meet the required specifications.

- Identify any defects or inconsistencies and take corrective action to ensure that the components are of high quality.

4. Safety

Profiling Machine Operators must follow all safety protocols and procedures to ensure that they and their coworkers are safe. They must be aware of the hazards associated with operating profiling machines and be able to take the necessary precautions to avoid accidents.

- Follow all safety protocols and procedures to ensure that they and their coworkers are safe.

- Be aware of the hazards associated with operating profiling machines.

- Take the necessary precautions to avoid accidents.

Interview Tips

Preparing for an interview for a Profiling Machine Operator position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace the interview:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website to learn about their history, products, and services.

- Read the job description carefully and identify the key skills and experience that the employer is looking for.

- Search for the company on Glassdoor to read reviews from current and former employees.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answer to these questions in advance so that you can deliver them confidently and clearly.

- Brainstorm a list of common interview questions and write out your answers.

- Practice delivering your answers out loud to a friend or family member.

- Time yourself to make sure that your answers are concise and within the time limit.

3. Prepare Questions to Ask the Interviewer

asking the interviewer questions at the end of the interview is a great way to show that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position.

- Come up with a list of questions that you would like to ask the interviewer.

- Make sure that your questions are relevant to the position and the company.

- Ask questions that show that you are interested in the company’s culture and values.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview to show that you are respectful of the interviewer’s time.

- Dress in a suit or business casual attire.

- Make sure your clothes are clean and wrinkle-free.

- Arrive for your interview on time.

Next Step:

Now that you’re armed with the knowledge of Profiling Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Profiling Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini