Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tool Profiling Machine Set-Up Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

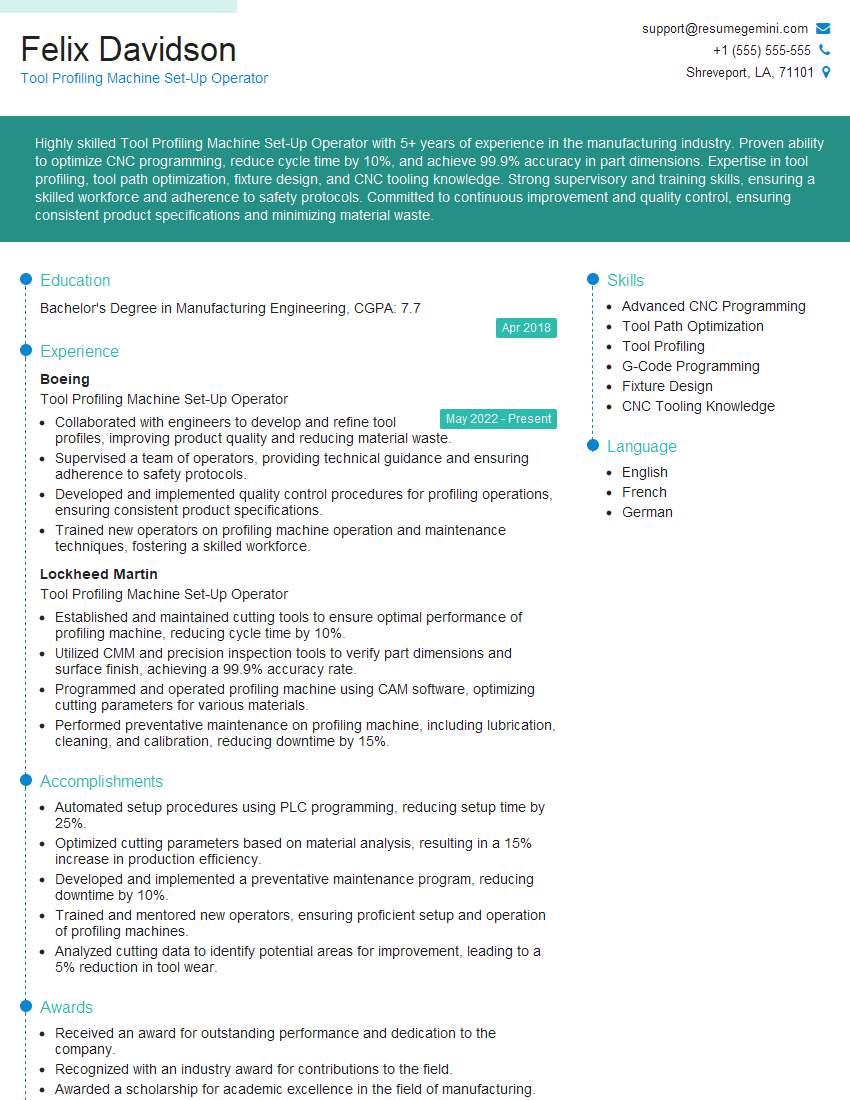

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Profiling Machine Set-Up Operator

1. What are the different types of tool profiling machines?

- Vertical Profiling Machine

- Horizontal Profiling Machine

- CNC Profiling Machine

- Optical Profiling Machine

2. What are the key features of a tool profiling machine?

Accuracy

- Linear Accuracy

- Angular Accuracy

Speed

- Feed Rate

- Rapid Traverse Rate

Rigidity

- Machine Bed

- Column

- Table

Control

- CNC Control

- Manual Control

3. What are the different types of tools used in tool profiling?

- End Mills

- Ball Nose End Mills

- Taper End Mills

- Bull Nose End Mills

- Drills

- Taps

- Reaming Tools

4. What are the different types of materials that can be profiled on a tool profiling machine?

- Metals

- Plastics

- Wood

- Composites

5. What are the different applications of tool profiling machines?

- Aerospace

- Automotive

- Medical

- Electronics

6. What are the safety precautions that must be taken when operating a tool profiling machine?

- Wear appropriate safety gear

- Keep the work area clean and free of debris

- Make sure the machine is properly grounded

- Never operate the machine if you are tired or under the influence of drugs or alcohol

7. What are the maintenance procedures that must be performed on a tool profiling machine?

- Clean the machine regularly

- Lubricate the machine according to the manufacturer’s recommendations

- Inspect the machine for any signs of wear or damage

- Calibrate the machine regularly

8. What are the troubleshooting tips for common problems that can occur with a tool profiling machine?

- If the machine is not cutting properly, check the tool for wear or damage

- If the machine is making a lot of noise, check for any loose parts

- If the machine is not moving smoothly, check for any obstructions

- If the machine is not stopping properly, check the brakes

9. What are the future trends in tool profiling machines?

- Increased use of CNC control

- Faster and more accurate machines

- More versatile machines

- More user-friendly machines

10. What are your strengths and weaknesses as a tool profiling machine set-up operator?

- Strengths

- I am a highly skilled and experienced tool profiling machine set-up operator

- I am proficient in all aspects of tool profiling, including machine set-up, operation, and maintenance

- I am a team player and I am always willing to help others

- I am a quick learner and I am always eager to learn new things

- Weaknesses

- I am sometimes too detail-oriented and I can get bogged down in the details

- I can be a bit of a perfectionist and I am sometimes not satisfied with my work until it is absolutely perfect

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Profiling Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Profiling Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Profiling Machine Set-Up Operators play a pivotal role in maintaining the efficiency and accuracy of tool profiling machines. They are responsible for setting up, calibrating, and maintaining these machines to ensure they produce high-quality profiled tools for various industries, including automotive, aerospace, and manufacturing.

1. Machine Set-Up and Operation

Prepare and configure tool profiling machines based on job specifications and engineering drawings, including workpiece properties and required tolerances.

- Mount and secure workpieces and cutting tools precisely using fixtures and CNC programs.

- Adjust machine settings, including spindle speed, feed rate, and tool offsets, to optimize cutting parameters based on material characteristics and desired results.

2. Tool Selection and Inspection

Select and install appropriate cutting tools based on workpiece material, geometry, and required surface finish.

- Inspect tools for wear, damage, or defects, and replace them as needed to maintain optimal cutting performance.

- Monitor and adjust tool life parameters to minimize downtime and maximize productivity.

3. Quality Assurance and Inspection

Conduct regular in-process and final inspections of profiled tools using measuring instruments and gauges.

- Verify dimensional accuracy, surface finish, and conformance to specifications, ensuring adherence to quality standards.

- Identify potential issues and make necessary adjustments to the machine or process to correct errors and maintain consistency.

4. Machine Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting procedures to ensure optimal machine performance and prevent breakdowns.

- Clean and lubricate machine components, change filters, and replace worn parts to maintain machine longevity.

- Diagnose and resolve machine malfunctions by analyzing error codes, inspecting components, and implementing corrective measures.

Interview Tips

To ace the interview for a Tool Profiling Machine Set-Up Operator position, thorough preparation is crucial. Here are some essential tips and hacks to help you impress the interviewer:

1. Research the Company and Position

Before the interview, take the time to thoroughly research the company and the specific position you are applying for. Understand their industry, products, and company culture. This knowledge will enable you to ask informed questions and demonstrate your interest in the role and the organization.

- Visit the company’s website to learn about their mission, values, and recent news.

- Read industry-specific publications and articles to stay up-to-date on the latest trends and technologies.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers beforehand. This will boost your confidence and help you articulate your skills and experience effectively.

- Anticipate questions related to your technical abilities, such as machine set-up, tool selection, and quality control processes.

- Prepare examples from your previous experience that demonstrate your problem-solving, decision-making, and teamwork skills.

3. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining tool profiling machines. Showcase your knowledge of CNC programming, cutting parameters, and tool inspection techniques.

- Quantify your achievements by providing specific metrics, such as the number of tools profiled or the reduction in production downtime due to effective maintenance.

- Discuss any certifications or specialized training you have received that demonstrate your expertise.

4. Showcase Your Quality-Oriented Mindset

Highlight your commitment to quality by emphasizing your attention to detail and adherence to industry standards.

- Provide examples of your ability to identify and correct errors in tool profiles, ensuring the production of high-quality parts.

- Discuss your understanding of quality control processes and your role in maintaining product consistency.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tool Profiling Machine Set-Up Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.