Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tool Shaper Set-Up Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

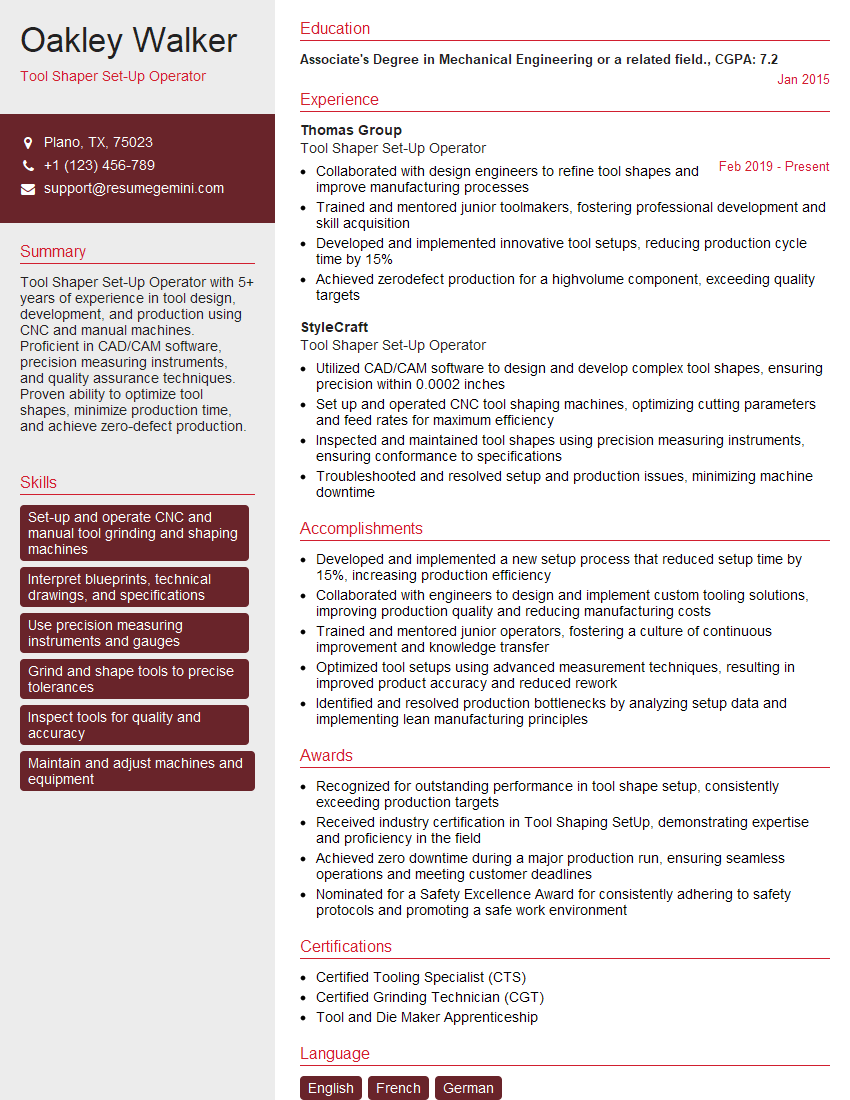

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Shaper Set-Up Operator

1. What are the different types of tool shapers and their uses?

There are various types of tool shapers, each designed for specific purposes:

- Horizontal Tool Shaper: Primarily used to cut straight or curved profiles on flat surfaces. Suitable for shaping dies, punches, and various components.

- Vertical Tool Shaper: Similar to the horizontal type, but the tool is mounted vertically. Ideal for shaping complex profiles, keyways, and irregularly shaped surfaces.

- Universal Tool Shaper: Offers a combination of horizontal and vertical movements, enabling the shaping of both flat and round surfaces. Suitable for machining gears and splines.

2. Describe the process of setting up a tool shaper machine?

Step 1: Mounting the Workpiece

- Secure the workpiece firmly on the table or fixture.

- Ensure accurate alignment and parallelism.

Step 2: Selecting and Mounting the Cutting Tool

- Choose the appropriate cutting tool for the material and profile.

- Mount the tool securely in the tool holder.

Step 3: Calculating Stroke Length and Speed

- Determine the desired stroke length based on the workpiece dimensions.

- Set the appropriate cutting speed to ensure efficient material removal.

3. What are the common problems encountered in tool shaping operations and how do you troubleshoot them?

Some common problems and troubleshooting tips include:

- Poor Surface Finish: Check cutting tool sharpness, adjust cutting speed and feed rate, and inspect for vibration.

- Inaccurate Dimensions: Verify machine alignment, workpiece positioning, and cutting tool wear. Calibrate the machine if necessary.

- Tool Breakage: Inspect for improper tool mounting, excessive feed rate, or workpiece hardness. Use the correct tool material and cutting parameters.

4. How do you maintain and calibrate a tool shaper machine?

Regular maintenance and calibration are essential for optimal performance:

- Lubrication: Lubricate moving parts frequently to prevent wear and tear.

- Cleaning: Regularly remove chips and coolant to maintain accuracy and prevent corrosion.

- Alignment: Periodically calibrate the machine to ensure precision and minimize errors.

5. What safety precautions should be followed when operating a tool shaper?

- Wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Securely mount the workpiece and cutting tool to prevent accidents.

- Never reach over the moving table or tool.

- Shut off the machine and disconnect the power before performing maintenance or adjustments.

6. Explain the different types of cutting tools used in tool shaper operations.

- Single Point Cutting Tools: These are made of high-speed steel or carbide and used for cutting various profiles.

- Form Tools: Designed to cut specific shapes, such as keyways, splines, and gears.

- Hollow Mills: Used for cutting cylindrical or spherical shapes.

7. How do you determine the correct cutting parameters for a given material?

- Consult manufacturer’s recommendations for speeds and feeds.

- Consider the material hardness, shape, and tolerance requirements.

- Start with conservative parameters and gradually increase them until optimal results are obtained.

8. What are the advantages of using a tool shaper compared to other machining processes?

- Precision: Tool shapers offer high accuracy and precision for complex profiles.

- Versatility: They can machine various materials and shapes with appropriate tooling.

- Efficiency: Tool shapers can automate repetitive operations, increasing productivity.

9. Describe the role of coolants in tool shaping operations.

- Lubrication: Coolants reduce friction and heat, extending tool life.

- Chip Removal: They flush away chips and debris, improving surface finish.

- Temperature Control: Coolants prevent excessive heating of the workpiece and machine components.

10. How do you inspect the quality of finished parts produced by a tool shaper?

- Dimensional Accuracy: Use precision measuring instruments like calipers and micrometers to verify dimensions.

- Surface Finish: Inspect the surface for any scratches, burrs, or imperfections.

- Geometric Tolerances: Ensure the workpiece meets specified tolerances for angles, roundness, and flatness.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Shaper Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Shaper Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tool Shaper Set-Up Operator is responsible for setting up, operating, and maintaining a variety of tool shaping machines. They work closely with engineers and other technicians to ensure that the machines are operating correctly and that the tools are producing the desired results. Key job responsibilities include:

1. Setting up and operating tool shaping machines

Tool Shaper Set-Up Operators must be able to set up and operate a variety of tool shaping machines, including CNC (computer numerical control) machines, grinders, and milling machines. They must be able to read and interpret blueprints and other technical drawings, and they must be able to make adjustments to the machines to ensure that the tools are producing the desired results.

- Set up and operate CNC machines, grinders, and milling machines

- Read and interpret blueprints and other technical drawings

- Make adjustments to machines to ensure that tools are producing the desired results

2. Maintaining tool shaping machines

Tool Shaper Set-Up Operators are also responsible for maintaining the tool shaping machines that they operate. This includes cleaning and lubricating the machines, and replacing worn or damaged parts. They must also be able to troubleshoot and repair problems with the machines.

- Clean and lubricate machines

- Replace worn or damaged parts

- Troubleshoot and repair problems with machines

3. Inspecting tools and parts

Tool Shaper Set-Up Operators must inspect the tools and parts that they produce to ensure that they meet the required specifications. They must be able to identify defects and make corrections as needed.

- Inspect tools and parts to ensure that they meet the required specifications

- Identify defects and make corrections as needed

4. Working with engineers and other technicians

Tool Shaper Set-Up Operators often work closely with engineers and other technicians to ensure that the tools and parts that they produce meet the required specifications. They must be able to communicate effectively with these other professionals and to work as part of a team.

- Work closely with engineers and other technicians

- Communicate effectively with other professionals

- Work as part of a team

Interview Tips

To ace an interview for a Tool Shaper Set-Up Operator position, it is important to be prepared and to demonstrate your skills and experience. Here are a few tips:

1. Research the company and the position

Before your interview, take the time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the position.

- Visit the company’s website

- Read news articles and press releases about the company

- Talk to people in your network who work for the company

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions

- Situation: Describe a situation that is relevant to the question

- Task: Explain the task that you were responsible for

- Action: Describe the actions that you took

- Result: State the results of your actions

3. Be prepared to talk about your skills and experience

The interviewer will want to know about your skills and experience as a Tool Shaper Set-Up Operator. Be prepared to discuss your experience with setting up and operating tool shaping machines, maintaining tool shaping machines, inspecting tools and parts, and working with engineers and other technicians.

- Quantify your accomplishments whenever possible

- For example, instead of saying “I set up and operated CNC machines,” say “I set up and operated CNC machines that produced over 10,000 parts per month.”

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic and positive about the position. Be sure to convey your passion for your work and your desire to contribute to the company.

- Smile and make eye contact with the interviewer

- Be polite and respectful

- Ask questions about the company and the position

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tool Shaper Set-Up Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tool Shaper Set-Up Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.