Are you gearing up for an interview for a Fixture Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Fixture Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

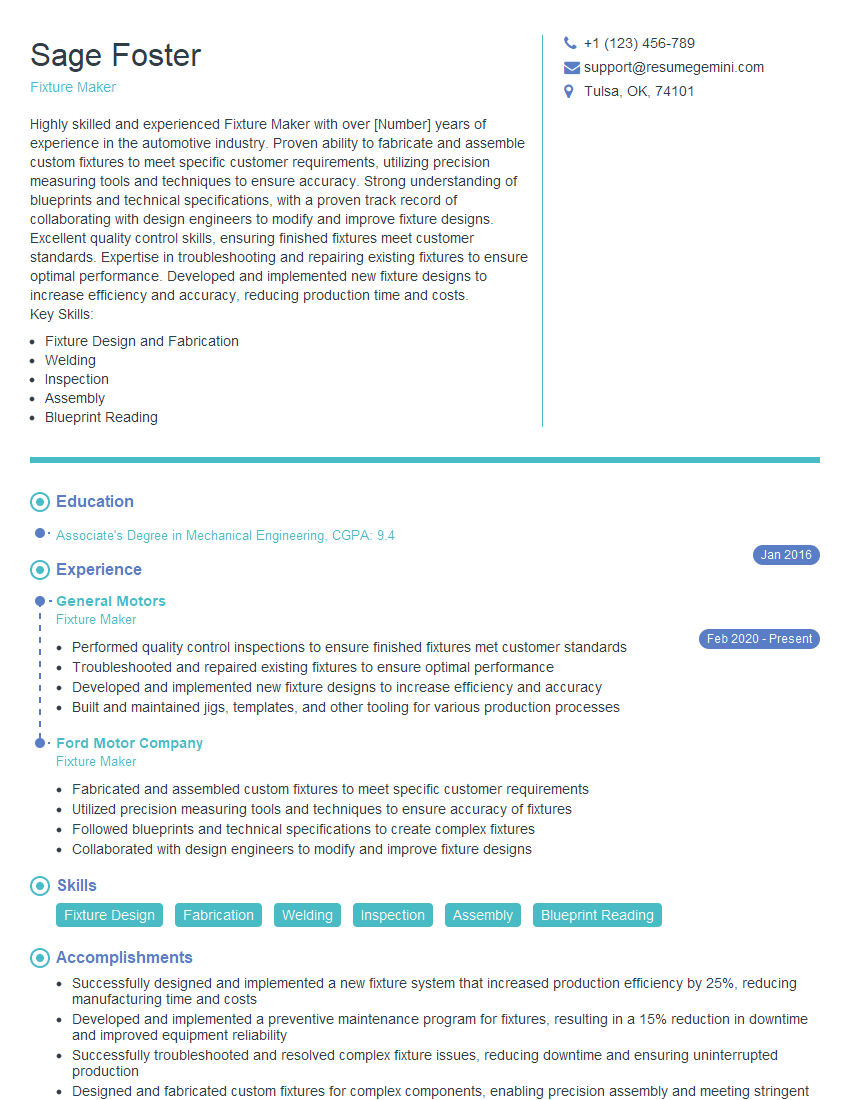

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fixture Maker

1. What are the primary responsibilities of a Fixture Maker?

As a skilled Fixture Maker, my key responsibilities would encompass:

- Designing and fabricating high-precision fixtures to enhance production efficiency and accuracy

- Analyzing component specifications and geometrical features to determine optimal fixture designs

2. Describe the different types of fixtures used in manufacturing.

Types of Fixtures

- Jig: Used to guide and hold workpieces during drilling, reaming, and other machining operations

- Fixture: General-purpose device that holds workpieces securely during assembly, inspection, and other processes

- Template: Used to mark or shape workpieces by following a predefined pattern or shape

3. What factors should be considered when designing a fixture?

When designing a fixture, I meticulously consider several crucial factors:

- Workpiece requirements: Type, dimensions, tolerances, and material properties of the workpiece being processed

- Production volume: Required throughput and cycle time

- Machining operations: Specific operations to be performed and the accuracy required

- Safety: Incorporating safety features to minimize risks to operators and ensure compliance with regulations

4. What materials are commonly used for fixture manufacturing?

In fixture manufacturing, I frequently work with a range of materials, including:

- Metals: Steel, aluminum, stainless steel

- Polymers: Nylon, polycarbonate

- Composites: Fiberglass-reinforced plastic, carbon fiber

- Ceramics: Used for high-temperature applications

5. How do you ensure the accuracy and precision of fixtures?

To ensure accuracy and precision, I adhere to the following practices:

- Precise measurements: Using precision measuring tools and machines to ensure that components meet specifications

- Quality control: Implementing quality checks throughout the manufacturing process to identify and correct errors

- Calibration: Regularly calibrating measuring equipment to maintain accuracy and reliability

6. What types of software programs do you use for fixture design?

I am proficient in utilizing industry-standard software programs for fixture design, including:

- CAD software: SolidWorks, AutoCAD

- CAM software: Mastercam, CAMWorks

- Simulation software: Ansys, Simulia

7. Describe the process of fixturing a workpiece.

Fixturing Process

- Workpiece preparation: Cleaning and inspecting the workpiece

- Fixture selection: Choosing the appropriate fixture based on workpiece requirements

- Fixture setup: Placing the workpiece in the fixture and securing it firmly

- Verification: Confirming that the workpiece is securely held and accurately positioned

8. What techniques do you use to minimize errors in fixture manufacturing?

To minimize errors, I employ the following techniques:

- Detailed planning: Thoroughly planning the fixture design and manufacturing process

- Error-proofing: Incorporating features into the fixture to prevent incorrect assembly or operation

- Continuous improvement: Regularly reviewing and refining processes to identify areas for improvement

9. What is the importance of fixture maintenance?

Regular fixture maintenance is crucial for several reasons:

- Accuracy and precision: Ensuring that fixtures continue to perform within the required tolerances

- Safety: Maintaining fixtures in good condition minimizes the risk of accidents or equipment failure

- Productivity: Preventing downtime caused by faulty or malfunctioning fixtures

10. How do you stay updated with the latest advancements in fixture technology?

I remain current with the latest advancements in fixture technology through various channels:

- Industry publications and conferences: Attending industry events and reading relevant publications

- Online resources: Exploring websites, forums, and technical articles

- Training and workshops: Participating in training programs and workshops offered by manufacturers and industry organizations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fixture Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fixture Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fixture Makers play a crucial role in manufacturing by creating and maintaining fixtures, specialized devices used to hold and position workpieces for efficient and accurate machining operations.

1. Fixture Design and Fabrication

Collaborate with engineers and designers to analyze and develop fixture designs.

- Read and interpret blueprints and technical drawings.

- Select appropriate materials and components.

- Utilize computer-aided design (CAD) software to create fixture schematics.

- Fabricate and assemble fixtures using various machine tools and equipment.

- Ensure fixtures meet specified tolerances and quality standards.

2. Fixture Installation and Maintenance

Install and mount fixtures on production machines.

- Align and level fixtures precisely.

- Troubleshoot and resolve any fixture-related issues during installation.

- Perform regular maintenance and repairs on fixtures to ensure optimal performance.

- Calibrate fixtures according to established specifications.

- Maintain accurate documentation and records of fixture maintenance activities.

3. Quality Control and Inspection

Monitor and inspect fixtures to ensure compliance with design specifications.

- Use precision measuring tools and equipment to verify fixture dimensions and tolerances.

- Identify and rectify any non-conformances or defects.

- Participate in quality control programs and inspections.

- Provide feedback to engineers and designers for fixture improvements.

4. Production Support

Provide technical support to production personnel in using and maintaining fixtures.

- Train operators on proper fixture usage and safety procedures.

- Assist in troubleshooting fixture-related problems during production.

- Suggest and implement process improvements to optimize fixture performance.

- Collaborate with other departments, such as engineering and production, to address fixture-related issues.

Interview Tips

To confidently ace the interview for a Fixture Maker position, consider the following tips:

1. Research the Company and Industry

Demonstrate your enthusiasm and preparedness by researching the company, its products or services, and the industry it operates in.

- Visit the company’s website and social media platforms.

- Read industry news and publications.

- Attend industry events and webinars.

2. Practice Your Answers

Anticipate common interview questions and practice your responses thoughtfully.

- Highlight your skills and experience in fixture design, fabrication, and maintenance.

- Provide specific examples of your contributions to previous projects or companies.

- Quantify your accomplishments when possible, using metrics and data to demonstrate your impact.

3. Showcase Your Technical Skills

Emphasize your proficiency in using machine tools, CAD software, and inspection equipment.

- Discuss your experience with different machining techniques and materials.

- Explain your understanding of fixture design principles and tolerancing.

- If applicable, mention any certifications or training programs you have completed.

4. Highlight Your Problem-Solving Abilities

Hiring managers seek candidates who can effectively troubleshoot and resolve fixture-related issues.

- Share examples of how you have solved complex fixture problems in the past.

- Discuss your analytical thinking process and attention to detail.

- Demonstrate your ability to collaborate with others to find solutions.

5. Ask Insightful Questions

Show your interest and engagement by asking thoughtful questions about the position, the company, and the industry.

- Inquire about the specific challenges and opportunities of the role.

- Ask for details about the company’s commitment to quality and innovation.

- Demonstrate your desire to learn and grow within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fixture Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!