Are you gearing up for a career in Fiber Designer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Fiber Designer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

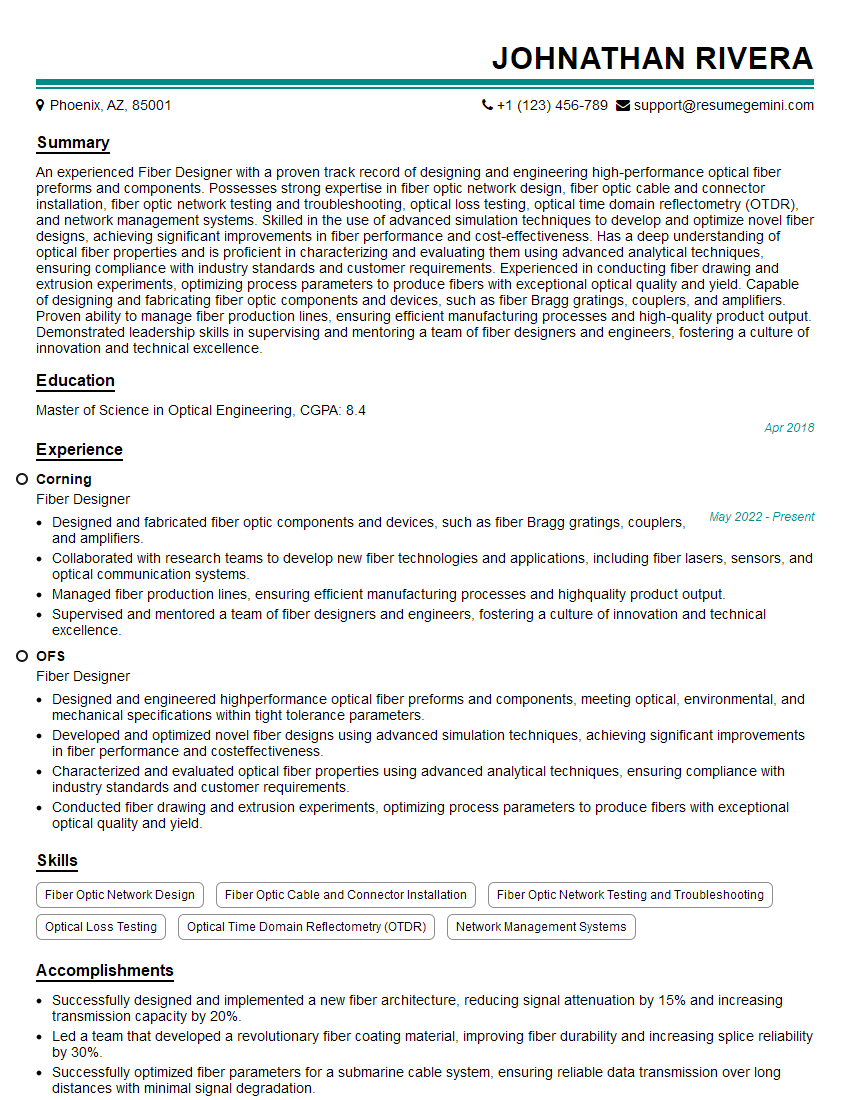

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiber Designer

1. What are the key considerations when designing fibers?

When designing fibers, several key considerations must be taken into account, including:

- Fiber type: The type of fiber being designed (e.g., glass, plastic, metal) will impact its properties and applications.

- Fiber geometry: The shape, size, and structure of the fiber will affect its strength, flexibility, and optical properties.

- Fiber material: The material composition of the fiber will determine its thermal, electrical, and chemical properties.

- Fiber coating: The coating applied to the fiber can protect it from environmental damage and improve its handling characteristics.

- Fiber performance: The desired performance characteristics of the fiber, such as strength, flexibility, optical loss, and temperature resistance, must be considered.

2. How do you optimize fiber properties for specific applications?

Fiber Selection

- Carefully consider the specific requirements of the application, including environmental conditions, mechanical stresses, and optical performance.

- Research and select the fiber type and geometry that best meets these requirements.

Fiber Design Refinement

- Fine-tune the fiber’s material composition, coating, and other parameters through simulations and experiments.

- Optimize the fiber’s properties to achieve the desired balance of strength, flexibility, optical performance, and durability.

Testing and Validation

- Thoroughly test the optimized fiber design to ensure it meets the application’s specifications.

- Make necessary adjustments to the design based on test results and feedback from end-users.

3. What software tools do you use for fiber design and analysis?

- Computer-aided design (CAD) software: For creating 3D models and simulating fiber behavior.

- Finite element analysis (FEA) software: For analyzing fiber stress, strain, and other mechanical properties.

- Optical modeling software: For simulating fiber propagation and optical properties.

- Data analysis and visualization software: For interpreting simulation results and generating reports.

- Industry-specific software: For fiber design and analysis tailored to specific applications, such as telecommunications or medical imaging.

4. What are the latest trends and advancements in fiber design?

- Specialty fibers: Development of fibers with unique properties, such as high strength, low loss, or biocompatibility.

- Composite fibers: Combining different materials to create fibers with tailored properties for specific applications.

- Nanofibers and microfibers: Exploring the unique properties and applications of fibers on a smaller scale.

- Metamaterials: Designing fibers with engineered optical properties for applications such as cloaking and perfect lensing.

- Sustainable fibers: Developing fibers from renewable or recycled materials to reduce environmental impact.

5. How do you stay updated on the latest developments in fiber design?

- Attend industry conferences and workshops: Network with experts and learn about the latest research and advancements.

- Read technical journals and publications: Stay abreast of scientific breakthroughs and new technologies.

- Collaborate with researchers and colleagues: Engage in discussions and exchange ideas to expand knowledge.

- Participate in online forums and discussion groups: Connect with other fiber designers and share experiences.

- ursue continuing education and professional development: Attend courses, workshops, or online programs to enhance skills and knowledge.

6. What is the role of experimental testing in fiber design?

- Validating design simulations: Comparing simulation results with experimental data to ensure accuracy and reliability.

- Characterizing fiber properties: Measuring actual fiber strength, flexibility, optical loss, and other performance parameters.

- Troubleshooting and failure analysis: Identifying manufacturing defects or performance issues by analyzing failed fibers.

- Refining design parameters: Using experimental results to adjust design parameters and optimize fiber performance.

- Quality control: Conducting routine testing to ensure that fibers meet specifications and maintain consistent quality.

7. How do you handle trade-offs in fiber design?

Balancing conflicting requirements in fiber design is essential. Here’s how I approach trade-offs:

- Identify critical parameters: Determine the most important fiber properties for the specific application.

- Prioritize requirements: Rank the critical parameters based on their significance and impact.

- Explore design alternatives: Investigate different fiber designs and materials to find optimal combinations.

- Use simulation and modeling: Predict the performance of different design options and identify potential trade-offs.

- Make informed decisions: Carefully consider the simulation results and prioritize the most critical parameters to make informed trade-offs.

8. What are your experiences with fiber manufacturing processes?

- Glass fiber drawing: Expertise in drawing glass fibers from preforms, controlling fiber diameter, and applying coatings.

- Polymer fiber extrusion: Experience in extruding polymer fibers, optimizing fiber properties through material selection and process parameters.

- Metal fiber production: Knowledge of techniques for producing metal fibers, such as melt spinning and electrospinning.

- Composite fiber fabrication: Experience in combining different materials to create composite fibers with tailored properties.

- Quality control and testing: Familiarity with fiber manufacturing quality control procedures and testing methods to ensure product quality.

9. How do you ensure the quality and consistency of fiber production?

- Establish clear specifications: Define detailed fiber specifications and ensure they are communicated to the manufacturing team.

- Implement quality control procedures: Set up regular testing and inspection procedures to monitor fiber properties and identify any deviations.

- Use statistical process control (SPC): Apply SPC techniques to analyze manufacturing data and identify trends or abnormalities.

- Calibrate equipment regularly: Ensure that all manufacturing equipment is calibrated and maintained to minimize variability.

- Train operators: Provide comprehensive training to manufacturing operators to ensure they understand the processes and quality standards.

10. What are some challenges you have faced in fiber design and how did you overcome them?

One challenging project involved designing a fiber for a medical imaging application. The fiber needed to be both flexible and strong to withstand the rigors of surgical procedures. I conducted extensive simulations to optimize the fiber geometry and material composition. I also worked closely with manufacturing engineers to develop a specialized coating process to enhance the fiber’s durability. Through iterative design and testing, we successfully created a fiber that met the demanding requirements of the application.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiber Designer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiber Designer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiber designers are responsible for the design and development of optical fibers, which are used in a variety of applications, including telecommunications, data transmission, and medical imaging. Their primary duties include:

1. Fiber Design and Optimization

Designing and optimizing optical fibers to meet specific requirements, such as transmission capacity, attenuation, and dispersion.

- Developing new fiber designs to improve performance and reduce costs.

- Simulating and modeling fiber behavior to optimize design parameters.

2. Material Selection and Characterization

Selecting and characterizing materials used in fiber fabrication, including glass, plastics, and coatings.

- Evaluating material properties and performance characteristics.

- Developing and optimizing material processing techniques.

3. Manufacturing Process Development

Developing and improving manufacturing processes for optical fibers.

- Designing and optimizing fiber drawing and coating equipment.

- Implementing quality control measures to ensure fiber quality and reliability.

4. Testing and Evaluation

Testing and evaluating optical fibers to ensure they meet specifications.

- Characterizing fiber performance using optical test equipment.

- Identifying and resolving any manufacturing defects or performance issues.

Interview Tips

Preparing for an interview for a Fiber Designer position requires a combination of technical knowledge and presentation skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This will demonstrate your interest in the position and enable you to ask informed questions during the interview.

2. Quantify Your Accomplishments

When describing your previous experience, focus on quantifying your accomplishments using specific metrics. This will help the interviewer understand the impact of your work and your potential contributions to their organization.

- For example, instead of saying “I designed optical fibers,” say “I designed optical fibers that reduced transmission loss by 20%.”

3. Be Prepared to Discuss Your Technical Skills

The interviewer will likely ask you about your technical skills in fiber design, such as your knowledge of fiber materials, fabrication techniques, and testing methods. Be prepared to provide detailed answers and demonstrate your understanding of these concepts.

4. Highlight Your Communication and Presentation Skills

Fiber designers often need to present their work to technical and non-technical audiences. Be prepared to demonstrate your communication and presentation skills by providing examples of presentations you have given or technical reports you have written.

5. Ask Informed Questions

At the end of the interview, the interviewer will typically ask if you have any questions. This is your opportunity to show your interest in the position and the company. Prepare a few thoughtful questions that demonstrate your understanding of the role and the organization’s goals.

- For example, you could ask about the company’s plans for future product development or the challenges they are facing in the industry.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Fiber Designer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Fiber Designer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.