Are you gearing up for an interview for a Head Machinist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Head Machinist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

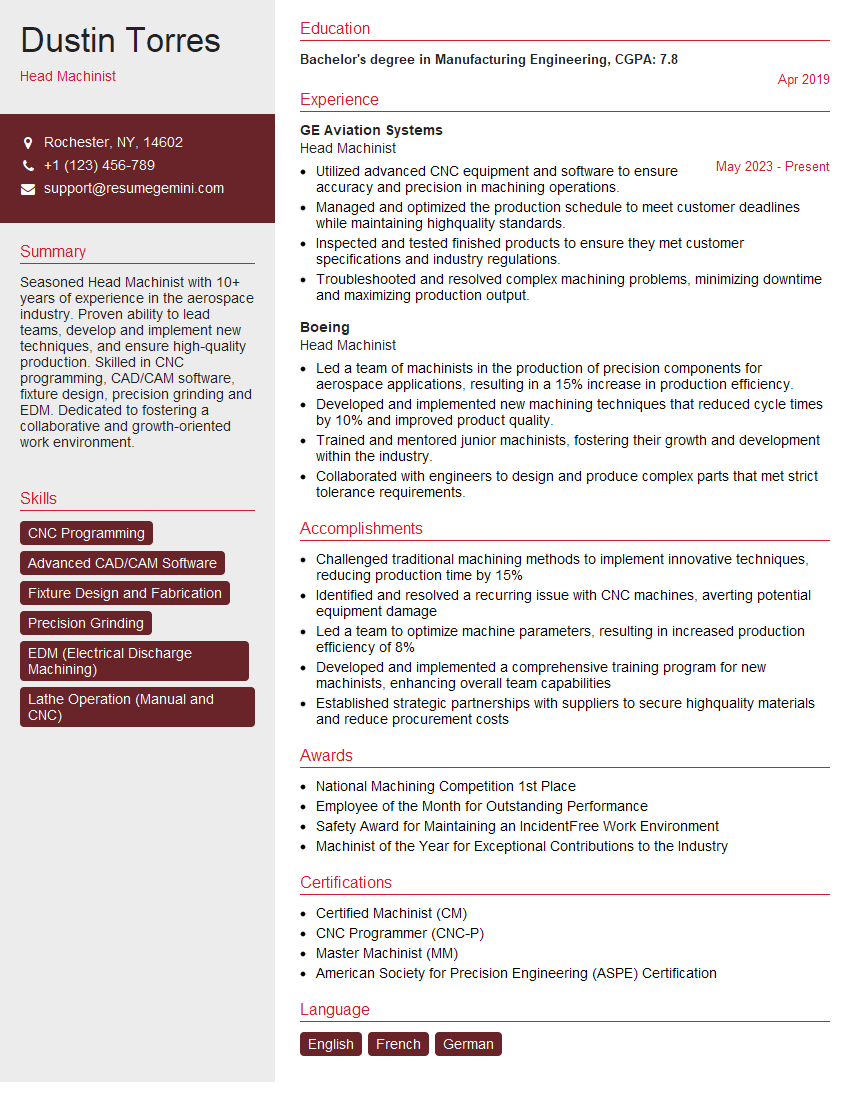

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Head Machinist

1. What are the different types of machining operations that you have experience with?

In my years of experience as a Head Machinist, I have gained expertise in various machining operations, including:

- Turning: Using lathes to create cylindrical or conical shapes by removing material from a rotating workpiece.

- Milling: Employing milling machines to remove material from a stationary workpiece using rotating cutters.

- Drilling: Using drill presses or CNC machines to create holes in materials.

- Grinding: Utilizing grinders to achieve high-precision dimensions and surface finishes by removing small amounts of material.

- Wire EDM: Applying electrical discharge machining techniques to cut complex shapes and intricate features.

2. Explain the importance of tool selection and setup for machining operations.

Tool Selection

- Selecting the appropriate cutting tools is crucial for efficient and precise machining.

- Factors considered include tool material, geometry, size, and coating.

- Proper tool selection optimizes cutting speeds, feed rates, and surface finishes.

Tool Setup

- Correctly setting up the tools is essential for accurate machining.

- This involves aligning the tools with the workpiece and ensuring proper cutting depths and offsets.

- Precise tool setup minimizes errors and improves machining quality.

3. How do you ensure the accuracy and precision of machined parts?

To ensure the accuracy and precision of machined parts, I employ various techniques:

- Using precision measuring instruments, such as calipers, micrometers, and coordinate measuring machines (CMMs).

- Implementing quality control procedures throughout the machining process.

- Regularly calibrating and maintaining machinery to minimize errors.

- Working with skilled machinists who are meticulous in their work.

- Continuously improving processes and implementing new technologies to enhance accuracy.

4. What are the different types of materials that you have experience machining?

Throughout my career, I have gained experience machining a wide range of materials, including:

- Metals: Steel, aluminum, titanium, brass, copper, and alloys.

- Plastics: Acrylic, polycarbonate, and various engineering plastics.

- Composites: Carbon fiber reinforced polymers (CFRP) and fiberglass reinforced plastics (FRP).

- Wood: Hardwoods and softwoods.

- Exotic materials: Inconel, Hastelloy, and other high-performance alloys.

5. How do you stay up-to-date with the latest advancements in machining technology?

To stay abreast of the latest advancements in machining technology, I engage in the following practices:

- Attending industry conferences, workshops, and seminars.

- Reading technical publications, journals, and white papers.

- Participating in online forums and discussion groups.

- Collaborating with equipment manufacturers and research institutions.

- Investing in training and development opportunities to enhance my knowledge and skills.

6. Explain the importance of preventative maintenance in a machine shop.

Preventative maintenance is crucial in a machine shop for several reasons:

- Reduces unplanned downtime and machine breakdowns, ensuring operational efficiency.

- Extends the lifespan of machinery and equipment, maximizing return on investment.

- Improves safety by minimizing the risk of accidents and injuries.

- Maintains the accuracy and precision of machines, enhancing product quality.

- Identifies potential problems early on, allowing for proactive repairs before they become major issues.

7. What are the different types of cutting fluids and their applications?

There are various types of cutting fluids, each with its specific applications:

- Soluble oils: Water-based fluids that provide cooling and lubrication.

- Synthetic fluids: Petroleum-based fluids that offer lubrication and corrosion protection.

- Semi-synthetic fluids: A combination of soluble oils and synthetic fluids, providing both cooling and lubrication.

- Straight oils: Pure mineral oils that offer lubrication and corrosion protection, but limited cooling.

- Cryogenic fluids: Super-cooled liquids or gases that provide extreme cooling for high-temperature applications.

8. Describe your experience with CNC programming and operation.

In my role as a Head Machinist, I have extensive experience in CNC programming and operation:

- Proficient in various CNC programming languages, such as G-code and Fanuc.

- Skilled in creating complex CNC programs for different machine tools, including lathes, mills, and machining centers.

- Expertise in optimizing CNC programs for efficiency, accuracy, and surface finish.

- Thorough understanding of CNC machine setup, operation, and troubleshooting.

- Experience with advanced CNC techniques, such as high-speed machining and 5-axis machining.

9. How do you manage a team of machinists and ensure productivity?

As a Head Machinist, I effectively manage a team of machinists and maintain high levels of productivity through the following strategies:

- Clear communication: Establishing clear expectations, goals, and deadlines.

- Effective delegation: Assigning tasks based on individual strengths and capabilities.

- Regular training and development: Investing in the skills and knowledge of my team.

- Performance monitoring and feedback: Tracking progress and providing constructive feedback to improve performance.

- Continuous improvement: Encouraging team members to identify and implement ways to enhance productivity.

10. What are your key strengths and weaknesses as a Head Machinist?

Strengths

- Strong technical skills and in-depth knowledge of machining processes.

- Excellent communication and interpersonal skills for effective team management.

- Proficient in CNC programming, operation, and troubleshooting.

- Passionate about continuous learning and staying up-to-date with industry advancements.

- Proven ability to optimize machining processes and improve productivity.

Weaknesses

- Tendency to be overly perfectionistic, which can sometimes slow down the production process.

- Limited experience in working with certain exotic materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Head Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Head Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Head Machinist is responsible for managing all aspects of the machine shop, including the selection, operation, and maintenance of all machinery. This individual will be responsible for the supervision of all employees within the shop, as well as for ensuring that all production goals are met and that all safety regulations are followed.

1. Machine Operation and Maintenance

The Head Machinist is responsible for the operation and maintenance of all machinery within the shop. This includes the selection of the correct machinery for each job, as well as the proper setup and operation of the machinery. The Head Machinist is also responsible for troubleshooting and repairing any machinery that may malfunction.

- Select and operate the appropriate machinery for each job.

- Set up and operate machinery according to specifications.

- Troubleshoot and repair machinery malfunctions.

- Maintain all machinery in good working order.

2. Production Management

The Head Machinist is responsible for the management of all production within the shop. This includes the scheduling of jobs, the allocation of resources, and the monitoring of progress. The Head Machinist is also responsible for ensuring that all production goals are met.

- Schedule jobs and allocate resources.

- Monitor production progress and make adjustments as needed.

- Ensure that all production goals are met.

3. Supervision

The Head Machinist is responsible for the supervision of all employees within the shop. This includes the training of new employees, the evaluation of employee performance, and the discipline of employees. The Head Machinist is also responsible for creating a positive and productive work environment.

- Train new employees.

- Evaluate employee performance.

- Discipline employees when necessary.

- Create a positive and productive work environment.

4. Safety

The Head Machinist is responsible for ensuring that all safety regulations are followed within the shop. This includes the identification of potential hazards, the implementation of safety procedures, and the training of employees on safety procedures. The Head Machinist is also responsible for investigating any accidents that may occur.

- Identify potential hazards.

- Implement safety procedures.

- Train employees on safety procedures.

- Investigate any accidents that may occur.

Interview Tips

Preparing for an interview for the position of Head Machinist is essential to increase your chances of making a good impression and getting the job. Here are some tips to help you prepare for and ace your interview:

1. Research the Company and the Position

Take the time to learn about the company’s history, mission, values, and products or services. This will show the interviewer that you are genuinely interested in the position and the company. You should also research the specific position you are applying for, including the key responsibilities and qualifications. This will help you to answer questions intelligently and demonstrate your understanding of the role.

- Visit the company’s website.

- Read articles about the company in industry publications.

- Talk to people in your network who work for the company.

- Review the job description carefully.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions ahead of time so that you can deliver your responses confidently and concisely. You can also prepare for questions that are specific to the position of Head Machinist, such as “What is your experience with CNC machining?” or “How do you manage a team of machinists?”

- Write out your answers to common interview questions.

- Practice answering questions out loud.

- Ask a friend or family member to interview you.

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills as a machinist. Be prepared to discuss your experience with different types of machinery, your knowledge of machining techniques, and your ability to work independently and as part of a team. You should also highlight any special skills or certifications that you have.

- Create a resume that highlights your experience and skills.

- Be prepared to talk about your experience in detail.

- Bring copies of any relevant certifications or licenses.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Arrive at the interview location 10-15 minutes early.

5. Be Confident and Enthusiastic

Confidence and enthusiasm are key to making a positive impression on the interviewer. Be confident in your abilities and in your ability to do the job. Show the interviewer that you are excited about the opportunity to work for the company.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Show enthusiasm for the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Head Machinist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!