Feeling lost in a sea of interview questions? Landed that dream interview for Printing Press Machinist but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Printing Press Machinist interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

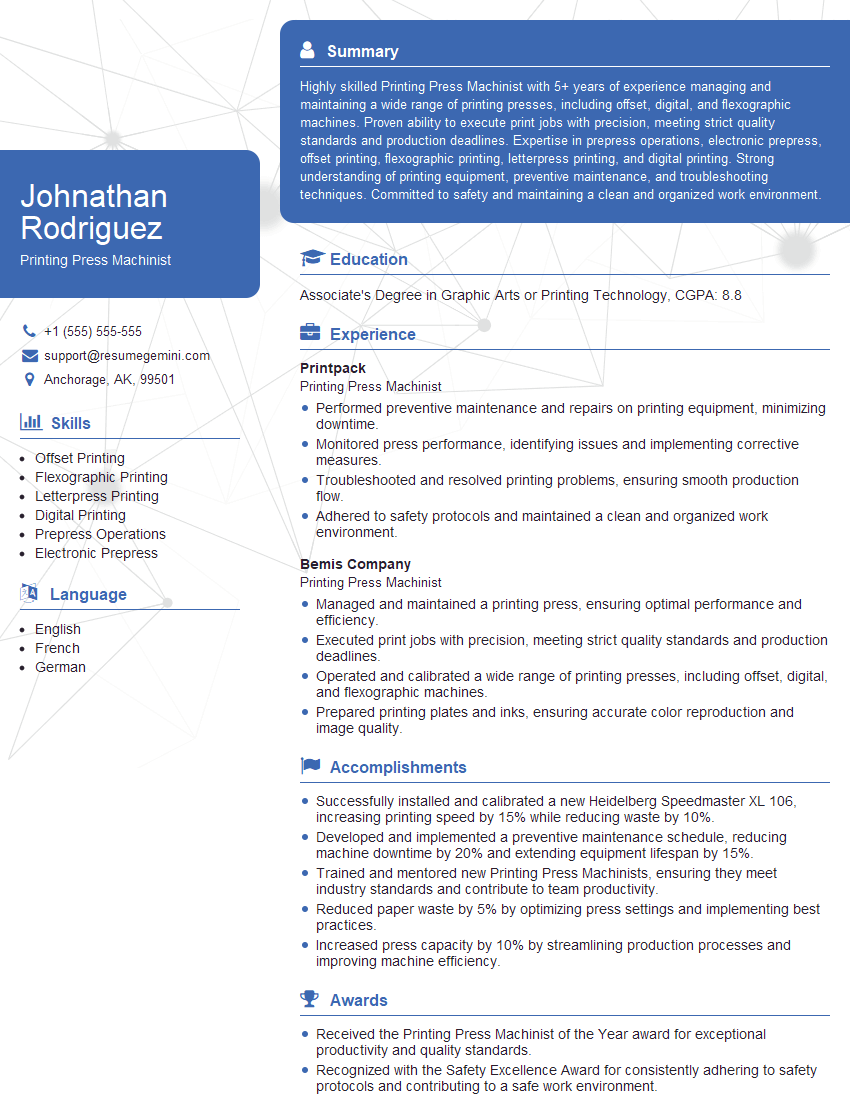

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printing Press Machinist

1. How do you ensure the accuracy of color reproduction in your printing process?

To ensure accurate color reproduction, I follow these steps:

- Calibrate and maintain printing equipment regularly.

- Use color profiles specific to the paper and ink being used.

- Proof prints and make adjustments as needed before full production.

- Inspect printed materials under controlled lighting conditions.

2. What techniques do you use to troubleshoot and resolve printing problems?

Identifying the problem

- Visually inspect the printed output to identify any defects.

- Check the printing equipment for any mechanical issues.

- Review the print job settings to ensure they are correct.

Resolving the problem

- Clean or replace printing plates or rollers.

- Adjust print settings such as ink flow or pressure.

- Calibrate the printing equipment if necessary.

3. How do you minimize waste and optimize efficiency in your printing process?

I implement the following strategies to minimize waste and optimize efficiency:

- Plan print jobs carefully to avoid overprinting or errors.

- Use automated equipment and technology to streamline production.

- Recycle paper and other printing materials.

- Establish preventive maintenance schedules to avoid unexpected breakdowns.

4. What safety precautions do you take when operating printing machinery?

I prioritize safety by adhering to these precautions:

- Wear appropriate safety gear, such as gloves and earplugs.

- Follow lockout/tagout procedures before servicing equipment.

- Maintain a clean and organized work area.

- Report any potential hazards or malfunctions to a supervisor.

5. How do you stay up-to-date with the latest printing technologies and trends?

To stay current, I engage in the following activities:

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Network with other printing professionals.

- Explore new equipment and software solutions.

6. Describe your experience in operating and maintaining different types of printing presses.

I have extensive experience operating and maintaining various printing presses, including:

- Offset presses

- Digital presses

- Flexographic presses

- Gravure presses

I am proficient in performing routine maintenance tasks, troubleshooting problems, and ensuring optimal performance.

7. How do you ensure the quality of printed materials meets customer specifications?

To ensure quality, I follow these steps:

- Review customer specifications carefully.

- Proof prints and make adjustments as needed before full production.

- Inspect printed materials during production to identify any defects.

- Work closely with customers to address feedback and meet their expectations.

8. What is your experience in using prepress and postpress equipment?

I have experience using a range of prepress and postpress equipment, including:

- Platemakers

- Proofers

- Cutting machines

- Binders

- Trimmers

- Laminators

Prepress

Postpress

I am proficient in operating these machines to ensure the smooth flow of production.

9. How do you handle tight deadlines and pressure in a fast-paced printing environment?

I prioritize tasks effectively and manage my time wisely to meet deadlines without compromising quality:

- Plan and schedule my work in advance.

- Break down large projects into smaller tasks.

- Communicate regularly with colleagues and supervisors.

- Stay focused and avoid distractions.

10. How do you ensure the confidentiality of customer information and sensitive materials?

I maintain the confidentiality of customer information and sensitive materials through the following practices:

- Limit access to sensitive materials only to authorized personnel.

- Securely store and dispose of customer data.

- Adhere to company policies and procedures regarding confidentiality.

- Report any potential security breaches promptly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printing Press Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printing Press Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Printing Press Machinists play a vital role in the printing industry. Their responsibilities are highly specialized and demand a combination of technical knowledge, precision, and attention to detail. The key responsibilities of a Printing Press Machinist are:

1. Preparing and Setting Up Printing Press

• Set up and prepare printing press according to job specifications.

• Install and adjust printing plates, blankets, and rollers.

• Inspect and maintain printing press to ensure proper functioning.

2. Operating and Monitoring Printing Press

• Operate printing press to produce high-quality prints.

• Monitor printing process and make necessary adjustments.

• Maintain consistent print quality by monitoring ink levels, paper flow, and other factors.

3. Troubleshooting Printing Press Issues

• Identify and resolve printing press malfunctions promptly.

• Conduct routine maintenance and repairs to keep the press in optimal condition.

• Perform cleaning and lubrication tasks as required.

4. Maintaining Quality Standards

• Ensure printed products meet or exceed quality standards.

• Inspect and verify printed materials for accuracy, color accuracy, and registration.

• Implement quality control procedures to maintain consistent output.

Interview Tips

Preparing for an interview for a Printing Press Machinist position requires careful planning. Here are some tips to help you ace the interview:

1. Research the Company and Position

• Familiarize yourself with the company, its products, and its industry.

• Thoroughly review the job description to understand the specific requirements and responsibilities.

• Prepare specific examples from your work experience that demonstrate your skills and qualifications.

2. Practice Answering Common Interview Questions

• Anticipate common interview questions and develop thoughtful responses.

• Prepare examples of your technical skills, problem-solving abilities, and attention to detail.

• Rehearse delivering your answers confidently and succinctly.

3. Highlight Your Expertise and Experience

• Emphasize your knowledge of printing press operations, troubleshooting, and maintenance.

• Showcase your experience in producing high-quality printed products.

• Provide specific examples of how your skills have contributed to the success of previous printing projects.

4. Demonstrate Your Problem-Solving Abilities

• Describe situations where you identified and resolved printing press issues effectively.

• Highlight your analytical skills and your ability to find innovative solutions.

• Share examples of how you have used troubleshooting techniques to minimize downtime and maintain press efficiency.

5. Be Prepared for Technical Questions

• Study basic printing press principles and terminology.

• Research common press components and their functions.

• Brush up on your knowledge of paper types, inks, and printing processes.

6. Dress Professionally and Arrive on Time

• Dress appropriately for the professional setting.

• Arrive on time for your interview to demonstrate your punctuality and respect for the interviewer’s time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Printing Press Machinist role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.