Are you gearing up for an interview for a Blast Furnace Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Blast Furnace Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

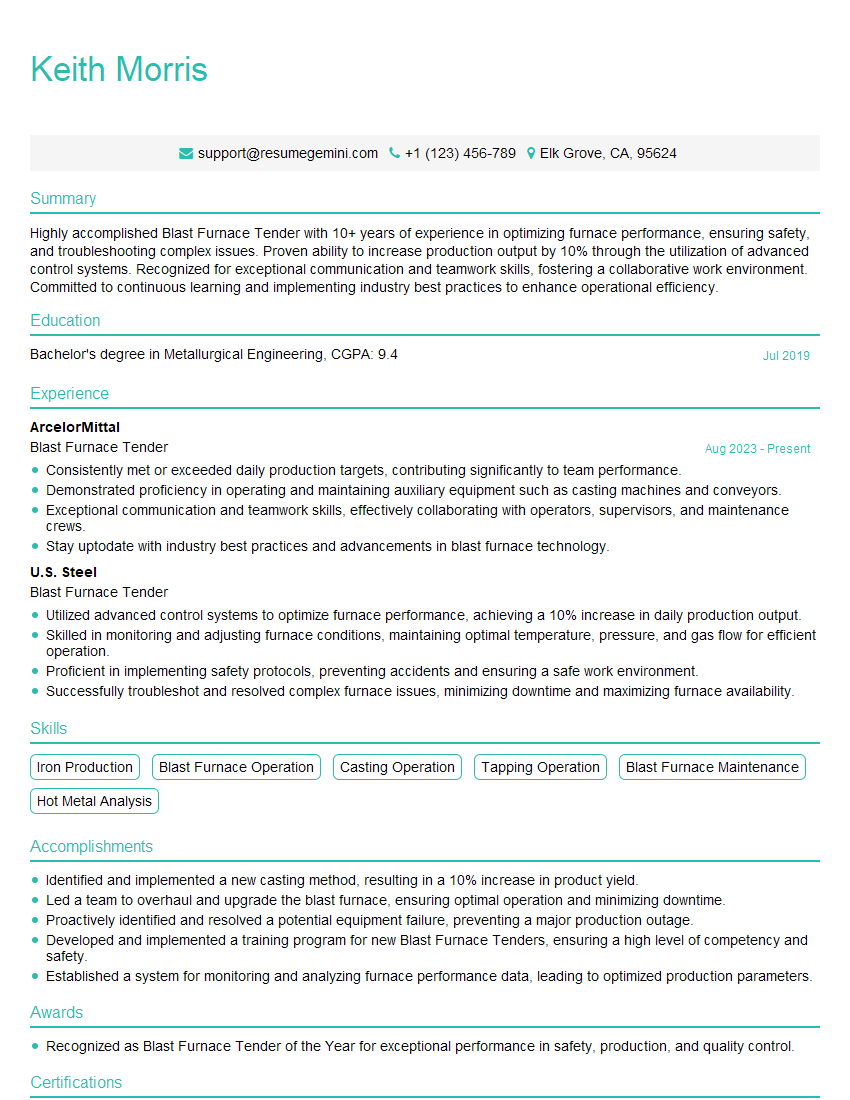

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blast Furnace Tender

1. What are the main responsibilities of a Blast Furnace Tender?

As a Blast Furnace Tender, I would be responsible for:

- Operating and monitoring the blast furnace.

- Adjusting the furnace controls to maintain optimal operating conditions.

- Monitoring the furnace’s performance and making adjustments as needed.

- Troubleshooting and resolving any issues that may arise.

- Ensuring the safety of the furnace and surrounding area.

2. What are the different types of blast furnaces, and how do they differ?

Hot Blast Furnaces

- Uses preheated air to increase the temperature of the blast.

- Improves fuel efficiency and productivity.

Cold Blast Furnaces

- Uses ambient air for the blast.

- Less efficient and productive than hot blast furnaces.

3. What are the key process parameters that must be controlled in a blast furnace operation?

The key process parameters that must be controlled in a blast furnace operation include:

- Temperature

- Pressure

- Gas flow rate

- Slag composition

- Iron composition

4. What are the potential hazards associated with blast furnace operation, and what safety precautions should be taken?

Potential hazards include:

- High temperatures

- Molten metal

- Toxic gases

- Explosions

Safety precautions include:

- Wearing appropriate protective clothing

- Following proper operating procedures

- Being aware of the potential hazards

- Having an emergency plan in place

5. What are the different roles and responsibilities of the team members involved in blast furnace operation?

The team members involved in blast furnace operation typically include:

- Blast Furnace Tender

- Foreman

- Maintenance Technician

- Quality Control Inspector

Each team member has specific roles and responsibilities to ensure the safe and efficient operation of the blast furnace.

6. What are the key maintenance procedures that must be performed on a blast furnace?

Key maintenance procedures include:

- Regular inspections

- Lubrication

- Repairs

- Overhauls

Proper maintenance is essential to ensure the long-term reliability and safety of the blast furnace.

7. What are the environmental regulations that apply to blast furnace operations?

Environmental regulations may vary depending on the location of the blast furnace. Common regulations include:

- Air pollution control

- Water pollution control

- Waste management

Blast furnace operators must comply with all applicable environmental regulations.

8. What are the latest technological advancements in blast furnace operation?

Recent technological advancements include:

- Improved process control systems

- New refractory materials

- Advanced monitoring and diagnostic techniques

These advancements have helped to improve the efficiency, productivity, and safety of blast furnace operations.

9. What are the future trends in blast furnace operation?

Future trends include:

- Increased automation

- Greater use of renewable energy sources

- Development of new and more sustainable ironmaking technologies

These trends are expected to shape the future of blast furnace operation and the iron and steel industry as a whole.

10. How would you handle a situation where the blast furnace is experiencing a major operating issue?

In the event of a major operating issue, I would:

- Identify the problem and assess its severity.

- Notify the foreman and other relevant personnel.

- Implement the appropriate troubleshooting procedures.

- Take steps to minimize the impact of the problem.

- Monitor the situation and make adjustments as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blast Furnace Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blast Furnace Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blast Furnace Tenders are responsible for overseeing proper operation of blast furnace and related equipment within steel mill or iron foundry. They need to have ability to analyze and adjust operating variables to maintain efficiency and ensure production of high-quality iron or steel. Key responsibilities include:

1. Furnace Operation and Maintenance

Monitor and control all aspects of blast furnace operation, including charging, tapping, and slag removal. Ensure smooth and efficient operation of equipment, performing routine maintenance and repairs as needed.

- Monitor furnace temperature, pressure, and other operating parameters.

- Adjust raw material composition, fuel flow, and airflow to optimize production.

- Perform preventive and corrective maintenance on furnace and related equipment.

- Inspect and repair refractory lining, tuyere cooler, and other critical components.

2. Production Control

Monitor and maintain desired iron or steel production rates and quality. Analyze process data and make adjustments to optimize yield and minimize waste. Ensure compliance with production specifications and quality standards.

- Monitor and control raw material proportions, including iron ore, coke, and limestone.

- Adjust operating parameters to control hot metal temperature, composition, and quality.

- Collect and analyze process data to identify areas for improvement and efficiency gains.

- Coordinate with other departments, such as quality control and maintenance, to ensure smooth production.

3. Safety and Environmental Compliance

Prioritize safety in all operations. Follow established safety procedures and wear appropriate protective gear. Ensure compliance with environmental regulations and minimize emissions. Maintain a clean and safe work environment.

- Follow established safety protocols and maintain hazardous materials handling procedures.

- Inspect equipment regularly to identify potential hazards and mitigate risks.

- Monitor emissions and implement measures to reduce environmental impact.

- Dispose of waste materials and byproducts in an environmentally responsible manner.

4. Record Keeping and Reporting

Maintain accurate records of all production and maintenance activities. Report on furnace performance, production rates, and quality issues. Communicate with supervisors and other personnel as needed to ensure effective operations.

- Document furnace operating data, maintenance procedures, and production statistics.

- Report any deviations from production specifications or quality standards.

- Communicate with supervisors and other departments to provide updates on furnace operations.

- Participate in troubleshooting and problem-solving activities as needed.

Interview Tips

To prepare for a Blast Furnace Tender interview, consider the following tips:

1. Research the Industry and Company

Learn about the iron and steel industry, including production processes, market trends, and industry challenges. Research the specific company you are applying to, their product line, and their place in the industry.

- Visit the company website and read industry publications.

- Attend industry events or webinars.

- Network with professionals in the field.

2. Review Key Job Responsibilities

Familiarize yourself with the key responsibilities of a Blast Furnace Tender, as outlined in the job description. Highlight your skills and experience that align with these responsibilities, and prepare examples to demonstrate your capabilities.

- Review the job description carefully.

- Identify your transferable skills and relevant experience.

- Prepare specific examples of your accomplishments.

3. Practice Answering Common Interview Questions

Anticipate common interview questions related to your technical skills, experience, and safety awareness. Prepare concise and articulate answers that showcase your qualifications and enthusiasm for the role. Consider using the STAR method to structure your responses:

- Situation: Describe a specific situation or challenge you faced.

- Task: Explain the task or responsibility you had to complete.

- Action: Describe the actions you took to address the situation or complete the task.

- Result: Share the positive outcomes or results of your actions.

4. Emphasize Safety and Environmental Compliance

Safety and environmental compliance are paramount in the iron and steel industry. Highlight your commitment to safety and your understanding of environmental regulations. Share examples of your experience in implementing and maintaining safety protocols and minimizing environmental impact.

- Describe your safety training and certifications.

- Provide examples of your safety initiatives or improvements.

- Discuss your knowledge of environmental regulations and your experience in reducing emissions or waste.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blast Furnace Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.