Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Converter Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

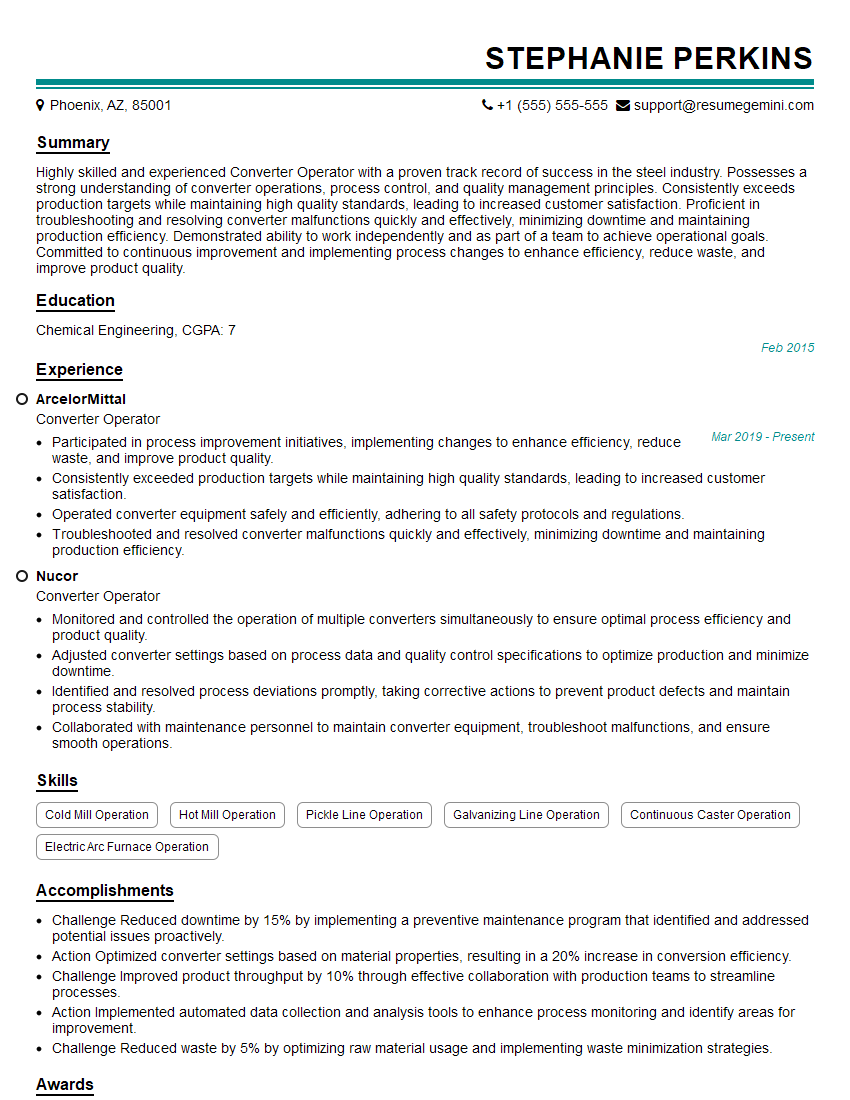

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Converter Operator

1. Describe the key responsibilities of a Converter Operator.

As a skilled Converter Operator, I am entrusted with various responsibilities crucial to the smooth functioning of the production line. These include:

- Operating and monitoring converter machinery to convert raw materials into finished products.

- Ensuring optimal operating parameters and equipment efficiency by performing routine maintenance and troubleshooting.

- Adhering to established safety protocols to maintain a safe and compliant work environment.

- Collaborating with production teams to plan and execute conversion processes effectively.

- Maintaining accurate records and documentation related to conversion operations.

2. Explain the process of converting raw materials into finished products using a converter.

The conversion process typically involves the following steps:

Raw Material Preparation

- Inspecting raw materials to ensure they meet specifications.

- Preparing raw materials by adding necessary additives or modifiers.

Conversion

- Loading raw materials into the converter.

- Initiating and monitoring the conversion process, ensuring proper temperature, pressure, and other parameters.

- Controlling the reaction time and conditions to achieve desired product quality.

Finishing

- Unloading the converted product from the converter.

- Performing any necessary post-processing steps, such as cooling or curing.

- Inspecting the finished product to ensure it meets specifications.

3. How do you ensure the quality of converted products?

Ensuring product quality is paramount to my role. I employ the following measures:

- Rigorously following established operating procedures and quality standards.

- Regularly calibrating and maintaining equipment to ensure accuracy and precision.

- Performing thorough inspections of raw materials, intermediate products, and finished products.

- Adhering to sampling and testing protocols to verify product quality.

- Implementing corrective actions promptly to address any identified quality deviations.

4. Describe the safety protocols you follow while operating a converter.

Safety is my utmost priority. I strictly adhere to the following protocols:

- Wearing appropriate personal protective equipment (PPE), including gloves, safety glasses, and protective clothing.

- Following lockout/tagout procedures when servicing or repairing equipment.

- Maintaining a clean and organized work area to minimize hazards.

- Being aware of potential hazards, such as high temperatures, electrical hazards, and chemical spills.

- Undergoing regular safety training and refresher courses.

5. What are the common challenges you face as a Converter Operator and how do you overcome them?

In this role, I encounter various challenges, including:

- Equipment malfunctions: I promptly troubleshoot and repair equipment to minimize downtime.

- Raw material inconsistencies: I work closely with suppliers to ensure raw material quality and adjust conversion parameters accordingly.

- Product quality deviations: I analyze process data and implement corrective actions to maintain product specifications.

- Production deadlines: I prioritize tasks effectively and coordinate with other operators to meet production targets.

- Safety concerns: I prioritize safety by following established protocols and continuously assessing potential risks.

6. How do you stay updated on the latest industry best practices and technological advancements in converter operations?

To remain proficient, I engage in ongoing learning and development:

- Attending industry conferences and workshops.

- Reading technical publications and research papers.

- Participating in online forums and discussions.

- Consulting with experts and vendors to exchange knowledge and insights.

- Seeking opportunities for professional development and certification.

7. What is your experience in troubleshooting and resolving technical issues with converters?

Troubleshooting is a crucial aspect of my role. I possess the following skills:

- Identifying and diagnosing equipment malfunctions through observation and data analysis.

- Applying my knowledge of converter systems to identify the root cause of issues.

- Utilizing diagnostic tools and techniques to pinpoint specific problems.

- Performing repairs and replacements to restore equipment functionality.

- Documenting troubleshooting procedures and findings for future reference.

8. How do you handle situations where the converter is operating at a reduced capacity?

When the converter operates at reduced capacity, I take the following steps:

- Analyze process parameters and identify potential bottlenecks.

- Inspect equipment for any signs of wear or damage.

- Review maintenance records and perform necessary repairs or adjustments.

- Collaborate with production teams to optimize workflow and minimize downtime.

- Monitor the situation closely and make adjustments as needed to restore full capacity.

9. What is your experience in working with automated systems in a converter operation?

I have extensive experience working with automated systems in converter operations:

- Programming and operating programmable logic controllers (PLCs) to control converter processes.

- Configuring and monitoring distributed control systems (DCSs) to automate converter operations.

- Utilizing data acquisition systems to collect and analyze process data.

- Trouble-shooting and resolving issues with automated systems to ensure smooth operation.

10. How do you ensure that the converter is operating in compliance with environmental regulations?

Ensuring environmental compliance is a key responsibility in my role:

- Monitoring converter emissions and ensuring they meet regulatory standards.

- Implementing pollution control measures, such as scrubbers and filters.

- Properly disposing of waste materials and hazardous substances.

- Adhering to environmental management systems and protocols.

- Participating in environmental audits and inspections to ensure compliance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Converter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Converter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Converter Operators play a vital role in converting raw materials into finished products, ensuring efficient and safe operations. Their responsibilities include:

1. Operation of Converters

Operate and monitor converters to convert raw materials into desired products. Control temperature, pressure, and other process parameters to maintain optimal conversion efficiency.

- Monitor and adjust converter operating parameters based on process specifications.

- Troubleshoot and resolve operational issues to minimize downtime and maintain production targets.

2. Sampling and Analysis

Collect samples of raw materials and finished products for quality control analysis. Conduct tests and interpret results to ensure product specifications are met.

- Perform chemical and physical tests to verify product quality.

- Identify deviations from specifications and initiate corrective actions.

3. Equipment Maintenance

Perform routine maintenance and repairs on converters and associated equipment. Ensure equipment is operating at peak efficiency and prevent breakdowns.

- Clean and inspect converters and ancillary equipment.

- Replace worn or damaged parts and perform minor repairs.

4. Safety and Compliance

Follow established safety protocols and adhere to environmental regulations. Maintain a clean and organized work area to prevent accidents and ensure compliance.

- Wear appropriate safety gear and follow established safety guidelines.

- Dispose of hazardous materials in accordance with environmental regulations.

Interview Tips

To ace the interview for a Converter Operator position, consider the following preparation tips:

1. Research the Role and Company

Thoroughly research the specific requirements of the Converter Operator role and the company’s operations. This will demonstrate your enthusiasm and understanding of the industry.

- Read the job description and company website to gather information about the position and organization.

- Prepare questions to ask the interviewer about the company’s culture, values, and growth opportunities.

2. Highlight Relevant Experience and Skills

Emphasize your practical experience in converter operation and related areas. Quantify your accomplishments and provide specific examples of your success.

- Discuss your experience monitoring and controlling converter parameters, conducting sampling and analysis, and performing equipment maintenance.

- Provide examples of how you have improved efficiency, reduced downtime, or resolved operational issues.

3. Demonstrate Safety Awareness

Safety is paramount in converter operations. Highlight your commitment to safety and knowledge of safety protocols.

- Emphasize your understanding of potential hazards associated with converter operations.

- Describe your experience following safety regulations, using personal protective equipment, and maintaining a clean and organized work environment.

4. Practice Common Interview Questions

Prepare for typical interview questions related to your skills, experience, and motivation. Practice your responses to present yourself confidently.

- Anticipate questions about your technical abilities, safety awareness, and problem-solving skills.

- Prepare examples of your past achievements that demonstrate your competence and work ethic.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Converter Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.