Are you gearing up for a career in Desilverizer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Desilverizer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

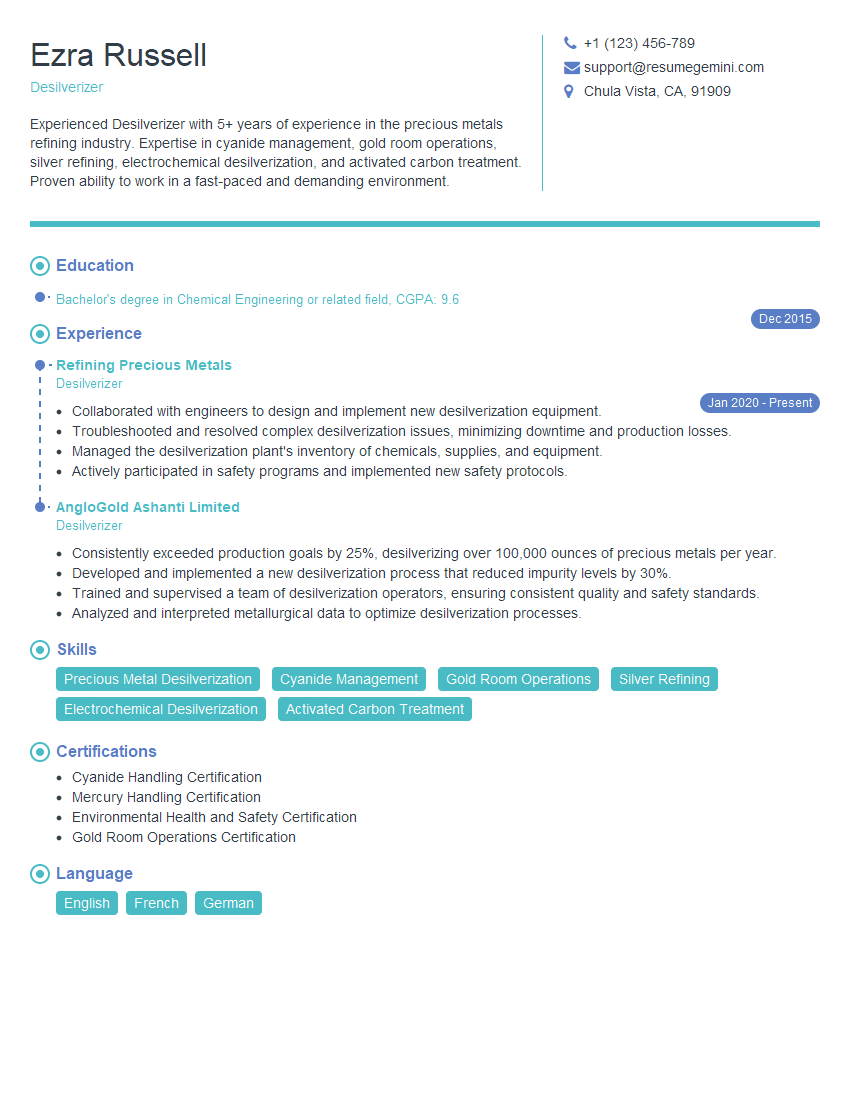

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Desilverizer

1. Explain the process of desilverizing lead bullion through the Parkes process?

When molten lead contains 1.5% to 2% silver, the Parkes process is employed for its extraction. The process involves the following steps:

- The lead bullion is heated in a desilverizing kettle to a temperature of around 800°C.

- Then, 1% zinc is added to the molten lead. Zinc has a higher affinity for silver than lead, so it reacts with the silver present in the lead to form a zinc-silver alloy.

- This alloy is lighter than lead and floats to the surface of the kettle. The alloy is skimmed off and allowed to solidify.

- The solidified alloy is then retorted to remove the zinc, leaving behind the silver.

2. How does the Bethell-Kelly process differ from the Parkes process?

Similarities

- Both processes are used to remove silver from lead.

- Both processes involve the use of zinc.

Differences

- In the Parkes process, zinc is added to molten lead, while in the Bethell-Kelly process, zinc is added to a lead-silver matte.

- In the Parkes process, the zinc-silver alloy is skimmed off, while in the Bethell-Kelly process, the alloy is tapped out of the furnace.

- In the Parkes process, the solidified alloy is retorted to remove the zinc, while in the Bethell-Kelly process, the alloy is treated with a flux to remove the zinc and lead, leaving behind the silver.

3. What are the advantages of the continuous counter-current decantation (CCD) process for the treatment of silver-bearing ores?

- The CCD process is a more efficient way to extract silver from ores than traditional batch processes, as it allows for the continuous removal of solids and the addition of fresh feed.

- The CCD process can be used to treat a wide variety of ores, including those with high levels of silver.

- The CCD process is a relatively low-cost process to operate, as it does not require the use of expensive equipment.

4. Describe the role of froth flotation in the recovery of silver from ores?

- Froth flotation is a process that is used to separate minerals from gangue based on their surface properties.

- In the case of silver ores, froth flotation is used to separate the silver-bearing minerals from the gangue minerals.

- The silver-bearing minerals are hydrophobized, or made water-repellent, while the gangue minerals are hydrophilic, or water-loving.

- When the ore is mixed with water and a frothing agent, the silver-bearing minerals will attach themselves to the bubbles of air and float to the surface, while the gangue minerals will sink to the bottom.

5. How is the Wohlwill process used to extract silver from cyanide solutions?

- The Wohlwill process is an electrolytic process that is used to extract silver from cyanide solutions, which are a byproduct of the cyanidation process for the extraction of gold.

- The process involves the use of a rotating cathode and a stationary anode in a cyanide solution containing silver.

- The silver ions in the solution are reduced to elemental silver at the cathode, and the elemental silver is deposited on the cathode.

- The Wohlwill process is a very efficient way to extract silver from cyanide solutions, and it is widely used in the gold mining industry.

6. What are the health and safety hazards associated with silver production?

- Silver dust and fumes can cause respiratory problems, such as irritation, coughing, and shortness of breath.

- Silver can also cause skin irritation and allergic reactions.

- Silver compounds, such as silver nitrate, can be toxic if ingested or inhaled.

- It is important to take appropriate precautions to protect workers from these hazards, such as wearing respirators and gloves, and washing hands thoroughly after handling silver.

7. What are the environmental impacts of silver production?

- Silver production can have a negative impact on the environment, due to the use of chemicals and the generation of wastewater.

- For example, the cyanidation process used to extract gold from ore can generate cyanide-contaminated wastewater, which can be harmful to aquatic life.

- Additionally, the mining of silver can lead to the destruction of natural habitats and the displacement of wildlife.

- It is important to take measures to minimize the environmental impact of silver production, such as using sustainable mining practices and recycling silver.

8. What are the current and future trends in silver production?

- The current trend in silver production is towards the use of more sustainable and environmentally friendly mining practices.

- Additionally, there is a growing interest in the use of recycled silver.

- In the future, it is likely that silver production will continue to grow, as silver is a valuable metal that is used in a wide variety of applications.

9. What are the key challenges facing the silver industry?

- The silver industry is facing a number of challenges, including the depletion of high-grade silver deposits.

- Additionally, the silver industry is facing increasing pressure to reduce its environmental impact.

- Another challenge facing the silver industry is the volatility of the silver price.

10. What are the opportunities for growth in the silver industry?

- The silver industry has a number of opportunities for growth, including the development of new silver deposits and the increased use of silver in new technologies.

- Additionally, the silver industry is benefiting from the growing demand for silver from emerging markets.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Desilverizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Desilverizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Desilverizer is a crucial role in the metal refining industry, responsible for removing impurities from silver and enhancing its purity.

1. Silver Desilverization Process

Operate desilverizing equipment, including furnaces, ladles, and casting machines, to separate silver from other metals.

- Monitor and control process parameters such as temperature, flow rates, and chemical composition.

- Identify and resolve process deviations to ensure efficient and safe operation.

2. Material Handling

Receive and handle silver-bearing materials, including bullion, scrap, and ores.

- Prepare and transport materials for processing.

- Maintain accurate records of material inventory and movement.

3. Quality Control and Analysis

Conduct analytical tests to determine the purity of silver and identify impurities.

- Use X-ray fluorescence (XRF) and other analytical techniques to measure metal content.

- Monitor process parameters and make adjustments to optimize silver recovery and purity.

4. Equipment Maintenance and Repair

Perform routine maintenance and repairs on desilverizing equipment.

- Identify potential issues and schedule preventive maintenance.

- Troubleshoot and resolve equipment malfunctions to minimize downtime.

Interview Tips

Preparing thoroughly for a Desilverizer interview is essential to showcase your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Learn about the company’s operations, including their refining process and quality standards.

- Research the industry and stay updated on advancements in desilverization technology.

- Demonstrate your understanding of the challenges and opportunities in the silver refining industry.

2. Highlight Your Technical Skills

Emphasize your proficiency in desilverization processes, analytical techniques, and equipment operation.

- Provide specific examples of how you have used your skills to improve silver recovery and purity.

- Describe your experience in troubleshooting and resolving equipment issues.

3. Communication and Teamwork

Desilverizers often work in teams and communicate with various stakeholders.

- Highlight your communication skills and ability to collaborate effectively.

- Share examples of how you have effectively communicated technical information to non-technical personnel.

4. Safety and Compliance

Emphasize your commitment to safety and compliance with industry regulations.

- Describe your experience in following safety protocols and handling hazardous materials.

- Demonstrate your knowledge of environmental regulations related to silver refining.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Desilverizer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Desilverizer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.