Feeling lost in a sea of interview questions? Landed that dream interview for Metal Reclamation Kettle Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metal Reclamation Kettle Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

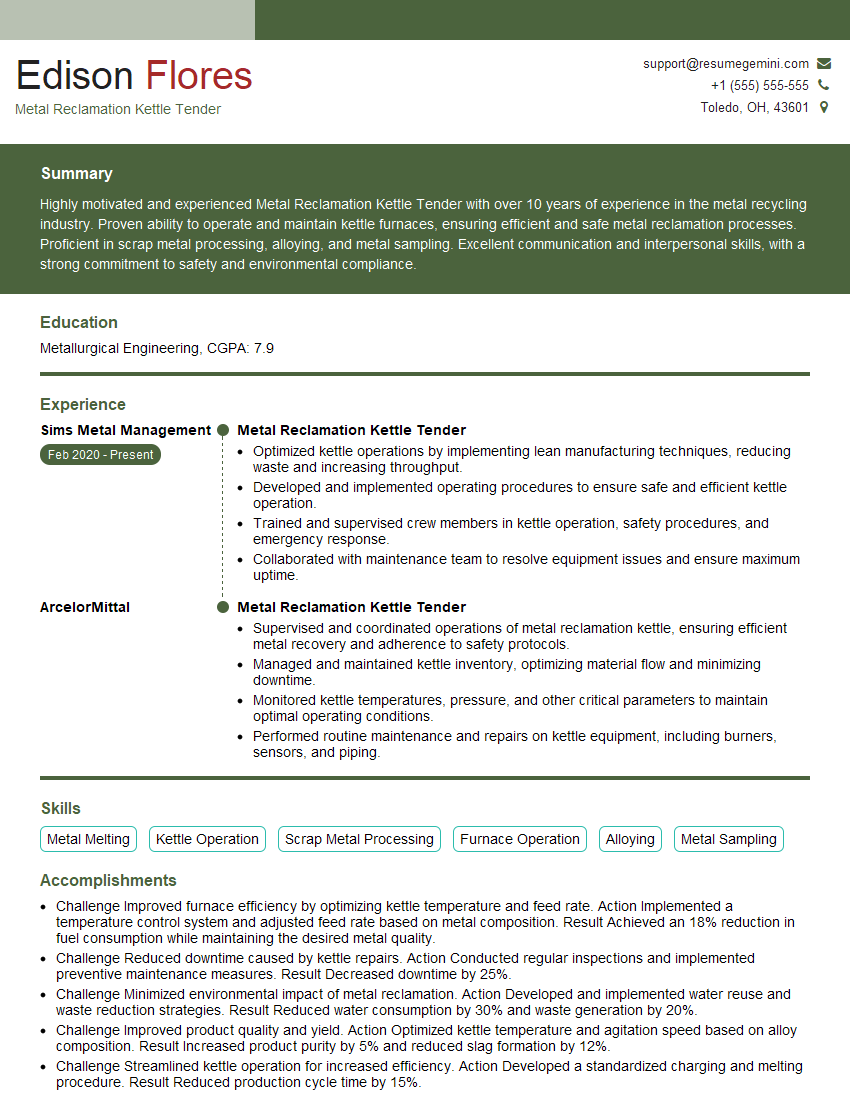

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Reclamation Kettle Tender

1. Explain the primary responsibilities of a Metal Reclamation Kettle Tender?

The primary responsibilities of a Metal Reclamation Kettle Tender include:

- Operate and maintain metal reclamation kettles to recover valuable metals from scrap metal.

- Monitor and control the temperature, pressure, and other operating parameters of the kettle to ensure efficient operation.

- Inspect and clean kettles and associated equipment to ensure safe and optimal performance.

- Load and unload scrap metal into and out of the kettle using appropriate equipment.

- Collect and dispose of hazardous waste generated during the metal reclamation process.

2. Describe the different types of metal reclamation kettles and their applications in the industry?

Types of Metal Reclamation Kettles

- Tilting Kettles: Used for melting and casting metals with low melting points, such as aluminum and zinc.

- Reverberatory Kettles: Utilized for melting high-temperature metals, such as steel and copper.

- Rotary Kettles: Employed for melting and refining metals that require continuous mixing, such as stainless steel.

- Induction Kettles: Used for melting and holding metals using electromagnetic induction, providing precise temperature control.

Applications

- Recycling and recovery of metals from scrap and waste materials.

- Production of new metal products from reclaimed materials.

- Purification and refining of metals to meet specific quality standards.

3. How do you monitor and control the temperature and pressure of a metal reclamation kettle?

To monitor and control the temperature and pressure of a metal reclamation kettle, I use the following techniques:

- Pyrometers: Non-contact temperature measurement devices to accurately measure kettle temperature.

- Pressure Gauges: Installed to monitor the internal pressure within the kettle.

- Control Systems: Automated systems that regulate fuel flow and air supply to maintain desired temperature and pressure levels.

- Regular Inspections: Visual checks and manual measurements to ensure proper operation of gauges and control systems.

4. What are the common safety hazards associated with operating metal reclamation kettles and how do you mitigate them?

Common safety hazards associated with operating metal reclamation kettles include:

- High Temperatures: Use protective clothing, gloves, and face shields to prevent burns.

- Toxic Fumes: Ensure proper ventilation and wear respirators to avoid inhalation of hazardous vapors.

- Molten Metal Splashes: Use splash guards and maintain a safe distance from the kettle during operation.

- Equipment Malfunctions: Regularly inspect and maintain equipment to prevent breakdowns and accidents.

5. How do you handle and dispose of hazardous waste generated during the metal reclamation process?

Hazardous waste generated during the metal reclamation process is handled and disposed of in the following manner:

- Identification and Segregation: Hazardous waste is identified, segregated, and labeled according to regulations.

- Storage and Transportation: Waste is stored in designated areas and transported by licensed hazardous waste carriers.

- Disposal Methods: Waste is disposed of through approved methods such as incineration, landfilling, or recycling, depending on its composition.

6. Explain the importance of maintaining accurate records when operating metal reclamation kettles?

Maintaining accurate records is crucial when operating metal reclamation kettles for several reasons:

- Production Tracking: Records document the amount and types of metal processed, allowing for production efficiency monitoring.

- Quality Control: Records provide evidence of the kettle’s operating parameters and metal quality, ensuring compliance with standards.

- Safety Compliance: Records demonstrate adherence to safety protocols, including temperature and pressure monitoring, and waste disposal procedures.

- Legal and Regulatory Requirements: Maintaining records is often required by regulations and can serve as proof of compliance during audits or investigations.

7. Describe your experience in troubleshooting common problems that arise during metal reclamation operations?

Common Problems

- Kettle Overheating: Check fuel supply, air flow, and temperature control systems.

- Poor Metal Quality: Analyze metal composition, adjust temperature and process parameters.

- Equipment Malfunctions: Inspect and repair or replace faulty components.

- Safety Issues: Immediately address any potential hazards, such as leaks or excessive fumes.

Troubleshooting Approach

- Identify the Problem: Observe the symptoms and gather information to determine the root cause.

- Analyze Possible Solutions: Consider various options and their potential outcomes.

- Implement the Solution: Safely and efficiently implement the chosen solution.

- Verify the Outcome: Monitor the system to ensure that the problem has been resolved.

8. How do you stay up-to-date on the latest advancements and best practices in metal reclamation techniques?

To stay up-to-date on the latest advancements and best practices in metal reclamation techniques, I engage in the following activities:

- Industry Publications and Journals: Subscribe to trade magazines and read articles on new technologies and methodologies.

- Conferences and Seminars: Attend industry events to learn from experts and network with professionals.

- Online Resources: Utilize online databases, websites, and discussion forums to access up-to-date information.

- Training and Certifications: Participate in training programs and obtain certifications to enhance my knowledge and skills.

9. Explain the importance of teamwork and communication in a metal reclamation operation?

Teamwork and communication are vital in a metal reclamation operation for several reasons:

- Safety: Clear communication ensures that all team members understand and follow safety protocols, minimizing risks.

- Efficiency: Effective communication streamlines tasks, reduces downtime, and improves productivity.

- Problem-Solving: Collaboration allows team members to share ideas and work together to find solutions to challenges.

- Continuous Improvement: Open communication fosters a culture of feedback and learning, leading to continuous improvement in operations.

10. Describe how you would approach implementing a new process or technology into a metal reclamation operation?

Implementation Approach

- Assessment and Planning: Evaluate the new process or technology, its potential benefits, and the required resources.

- Communication: Clearly communicate the changes to team members, stakeholders, and customers.

- Training: Provide comprehensive training to ensure that everyone is proficient in the new process or technology.

- Phased Implementation: Roll out the new approach gradually to minimize disruption and allow for adjustments.

- Monitoring and Evaluation: Regularly track and evaluate the performance of the new process or technology, making necessary adjustments as needed.

Benefits of Implementation

- Increased Efficiency: Streamlined processes and advanced technologies can boost productivity.

- Improved Quality: New methods may lead to higher-quality reclaimed metals.

- Reduced Costs: Optimization and automation can lower operational expenses.

- Environmental Sustainability: Advanced technologies may help reduce emissions and waste generation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Reclamation Kettle Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Reclamation Kettle Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Reclamation Kettle Tenders play a crucial role in the metal recycling industry, ensuring safe and efficient metal reclamation processes. Their primary responsibilities include:

1. Kettle Operation

Operate and maintain metal reclamation kettles, such as tilting and rotary furnaces.

- Monitor and adjust temperature, pressure, and other process parameters.

- Charge and discharge furnaces with scrap metal and other materials.

2. Quality Control

Control and ensure the quality of reclaimed metal.

- Test molten metal to determine its composition and quality.

- Identify and isolate defective metal or products.

3. Safety and Maintenance

Maintain a safe work environment and ensure the proper operation of equipment.

- Follow safety protocols and regulations.

- Inspect and maintain furnaces, equipment, and work areas.

4. Other Responsibilities

Perform additional tasks as assigned by supervisors.

- Clean and maintain equipment and work areas.

- Assist in production, quality control, and maintenance activities.

Interview Tips

To prepare effectively for an interview as a Metal Reclamation Kettle Tender, consider the following tips:

1. Research the Company and Role

Learn about the company’s metal recycling operations, their commitment to safety, and the specific requirements of the Kettle Tender position.

- Visit the company website, read industry news, and network with professionals in the field.

- Review the job description thoroughly to identify the key responsibilities and qualifications.

2. Prepare for Technical Questions

Be prepared to answer questions about your knowledge of metal reclamation processes, metallurgy, and furnace operations.

- Study the basics of metal recycling, including different types of metals, melting processes, and quality control techniques.

- Practice describing your experience operating and maintaining metal reclamation furnaces.

3. Highlight Safety and Environmental Awareness

Emphasize your commitment to safety and environmental protection in the metal recycling industry.

- Explain your understanding of safety protocols, hazardous materials handling, and environmental regulations.

- Discuss your experience in implementing safety measures and reducing environmental impact in previous roles.

4. Showcase Problem-Solving and Troubleshooting Skills

Demonstrate your ability to solve problems and troubleshoot issues with metal reclamation equipment and processes.

- Provide examples of situations where you identified and resolved problems in a metal reclamation setting.

- Explain your approach to troubleshooting and developing effective solutions.

5. Practice Your Communication and Interpersonal Skills

In this role, effective communication and interpersonal skills are essential for working with supervisors, colleagues, and customers.

- Practice your ability to clearly explain technical concepts and procedures.

- Demonstrate your willingness to collaborate and contribute to a team environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Reclamation Kettle Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.