Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Open Hearth Furnace Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

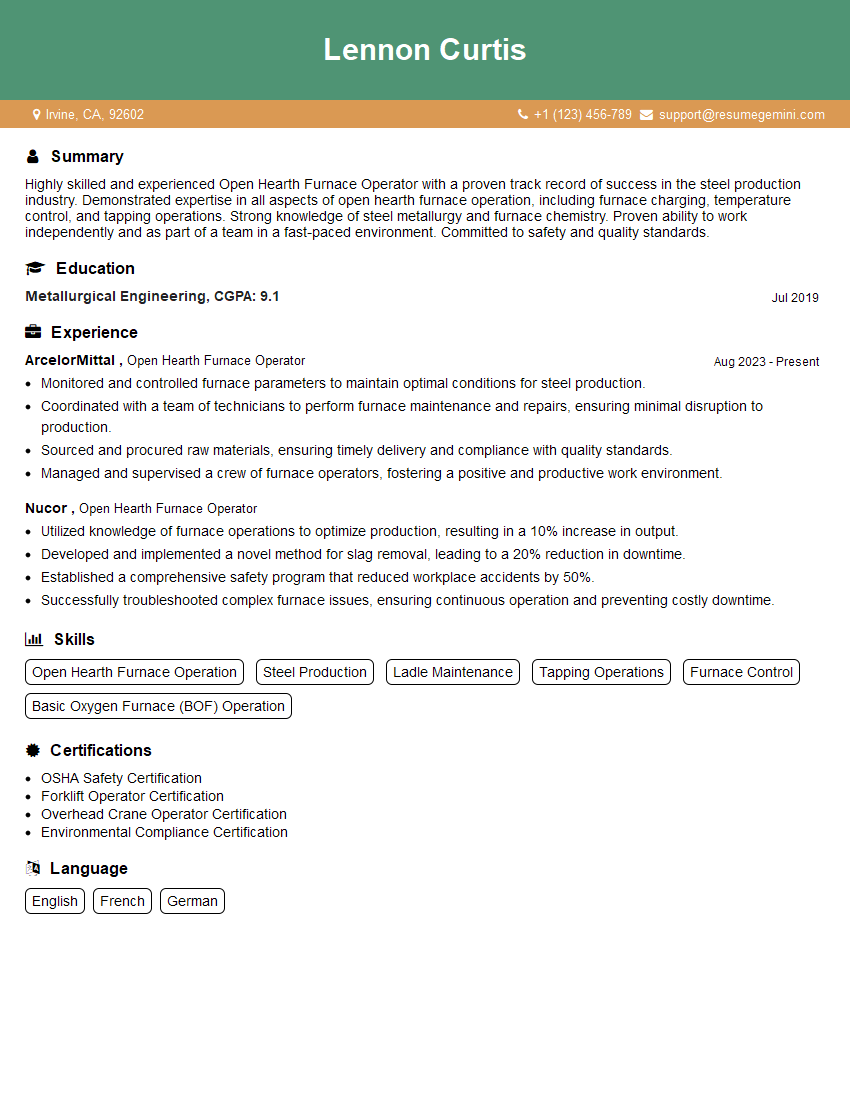

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Open Hearth Furnace Operator

1. Explain the key responsibilities of an Open Hearth Furnace Operator?

As an Open Hearth Furnace Operator, I would be responsible for:

- Monitoring and controlling the operation of the open hearth furnace to produce steel.

- Analyzing raw materials and determining the proper mix for each heat.

- Adjusting furnace settings to ensure optimal combustion and heat transfer.

- Taking samples of molten steel and performing quality tests.

- Ensuring compliance with safety regulations and operating procedures.

2. Describe the different types of open hearth furnaces and their applications?

There are two main types of open hearth furnaces:

Acid open hearth furnaces

- Use an acidic lining and are used to produce high-carbon steel.

- Characterized by their ability to remove impurities, such as phosphorus and sulfur.

- Commonly used in the production of structural steel, rails, and plates.

Basic open hearth furnaces

- Use a basic lining and are used to produce low-carbon steel.

- Capable of removing both acidic and basic impurities.

- Suitable for producing steel for automotive, shipbuilding, and machinery applications.

3. What are the critical control points in the operation of an open hearth furnace?

The critical control points in the operation of an open hearth furnace include:

- Raw material preparation: Proper mixing and sizing of raw materials ensure a consistent furnace charge.

- Furnace charging: Correct charging sequence and distribution are essential for efficient combustion and heat transfer.

- Combustion control: Maintaining optimal air-fuel ratio and flame temperature is crucial for maximizing heat input and minimizing fuel consumption.

- Slag formation and control: Slag acts as a protective layer and helps remove impurities. Controlling slag composition and viscosity is vital for furnace performance.

- Temperature monitoring: Accurate temperature measurement and control are essential for ensuring steel quality and preventing furnace damage.

- Tapping and casting: Proper timing and procedures during tapping and casting minimize defects and ensure product quality.

4. How do you optimize the efficiency and productivity of an open hearth furnace?

To optimize the efficiency and productivity of an open hearth furnace, I would focus on:

- Raw material optimization: Using high-quality raw materials and optimizing their mix can improve furnace efficiency and reduce production costs.

- Combustion optimization: Fine-tuning combustion parameters, such as air-fuel ratio and flame shape, can maximize heat utilization and minimize energy consumption.

- Slag management: Optimizing slag composition and fluidity through proper flux additions improves furnace performance and steel quality.

- Equipment maintenance: Regular maintenance and timely repairs of furnace components, such as burners, heat exchangers, and fans, ensure optimal operation and prevent costly breakdowns.

- Process control automation: Implementing automated control systems can improve accuracy, consistency, and efficiency in critical process parameters.

5. What are the common challenges faced by Open Hearth Furnace Operators and how do you overcome them?

Some common challenges faced by Open Hearth Furnace Operators include:

Furnace refractory wear

- Solution: Regular inspection and timely replacement of worn refractory lining to maintain furnace integrity and prevent premature failure.

Slag foaming

- Solution: Adjusting slag composition and viscosity through proper flux additions to control foaming and prevent operational issues.

Process interruptions

- Solution: Developing robust contingency plans, maintaining spare parts inventory, and implementing proactive maintenance practices to minimize downtime and maximize production.

6. What safety precautions should be taken when operating an open hearth furnace?

To ensure a safe operating environment, I would adhere to the following safety precautions:

- Personal protective equipment: Wear appropriate protective gear, including heat-resistant clothing, gloves, and eye protection.

- Hazard awareness: Be aware of potential hazards, such as extreme heat, molten metal, and toxic fumes.

- Safe work practices: Follow established operating procedures and avoid unauthorized access to dangerous areas.

- Emergency preparedness: Familiarize myself with emergency shutdown procedures and evacuation routes.

- Housekeeping: Maintain a clean and organized work area to prevent tripping hazards and other accidents.

7. Describe the role of automation in modern open hearth furnace operations?

Automation plays a significant role in modern open hearth furnace operations by:

- Process control: Automated systems monitor and control critical process parameters, such as temperature, gas flow, and slag composition, ensuring consistent and optimal furnace performance.

- Data acquisition and analysis: Sensors and data loggers collect real-time data, which can be analyzed to optimize furnace operation and predict maintenance needs.

- Safety enhancements: Automation can improve safety by reducing human error and providing early warnings of potential hazards.

8. How do you stay up-to-date with the latest advancements in open hearth furnace technology?

To stay up-to-date with the latest advancements in open hearth furnace technology, I would:

- Attend industry conferences and workshops: Participate in industry events to learn about new technologies and best practices.

- Read technical publications: Subscribe to trade journals and research papers to stay informed about technological developments.

- Network with industry professionals: Connect with experts in the field through online forums and professional organizations.

9. Why are you interested in this Open Hearth Furnace Operator position?

I am eager to join your organization as an Open Hearth Furnace Operator because:

- My passion for steelmaking: I have always been fascinated by the art and science of steel production, and I am excited about the opportunity to contribute to this vital industry.

- My technical skills: My strong technical foundation in metallurgy and furnace operations makes me confident in my ability to successfully operate an open hearth furnace.

- My commitment to safety: Safety is paramount in this role, and I am committed to adhering to all safety regulations and procedures.

10. What are your salary expectations for this position?

My salary expectations are commensurate with my experience and qualifications. I am open to discussing a competitive salary package that aligns with industry standards and the value I can bring to your organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Open Hearth Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Open Hearth Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Open Hearth Furnace Operator is responsible for the safe and efficient operation of open hearth furnaces, which are used to produce steel. Key responsibilities include:

1. Furnace Operation

Operating and maintaining open hearth furnaces, including charging the furnace with raw materials, controlling the temperature and atmosphere of the furnace, and tapping the molten steel.

2. Equipment Maintenance

Performing routine maintenance on furnaces and related equipment, including inspecting, cleaning, and repairing components as needed.

3. Quality Control

Monitoring and controlling the quality of steel produced, including taking samples and performing tests to ensure that the steel meets specifications.

4. Safety and Compliance

Following all safety protocols and regulations related to the operation of open hearth furnaces, including wearing appropriate protective gear and maintaining a clean and safe work environment.

Interview Tips

In order to ace an interview for an Open Hearth Furnace Operator position, it is important to prepare thoroughly and present yourself in a professional and confident manner.

1. Research the Company and Position

Take the time to learn about the company you are applying to and the specific position you are interviewing for. This will help you to tailor your answers to the interviewer’s questions and demonstrate your knowledge of the industry.

2. Practice Your Answers

Once you have a good understanding of the company and position, take some time to practice answering common interview questions. This will help you to feel more confident and prepared during the actual interview.

3. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic about the position and who have a positive attitude. Be sure to convey your passion for the steel industry and your eagerness to learn and grow.

4. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the position. For example, if you have experience operating open hearth furnaces or performing quality control, be sure to mention this in your answers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Open Hearth Furnace Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.