Are you gearing up for an interview for a Open Hearth Melter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Open Hearth Melter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

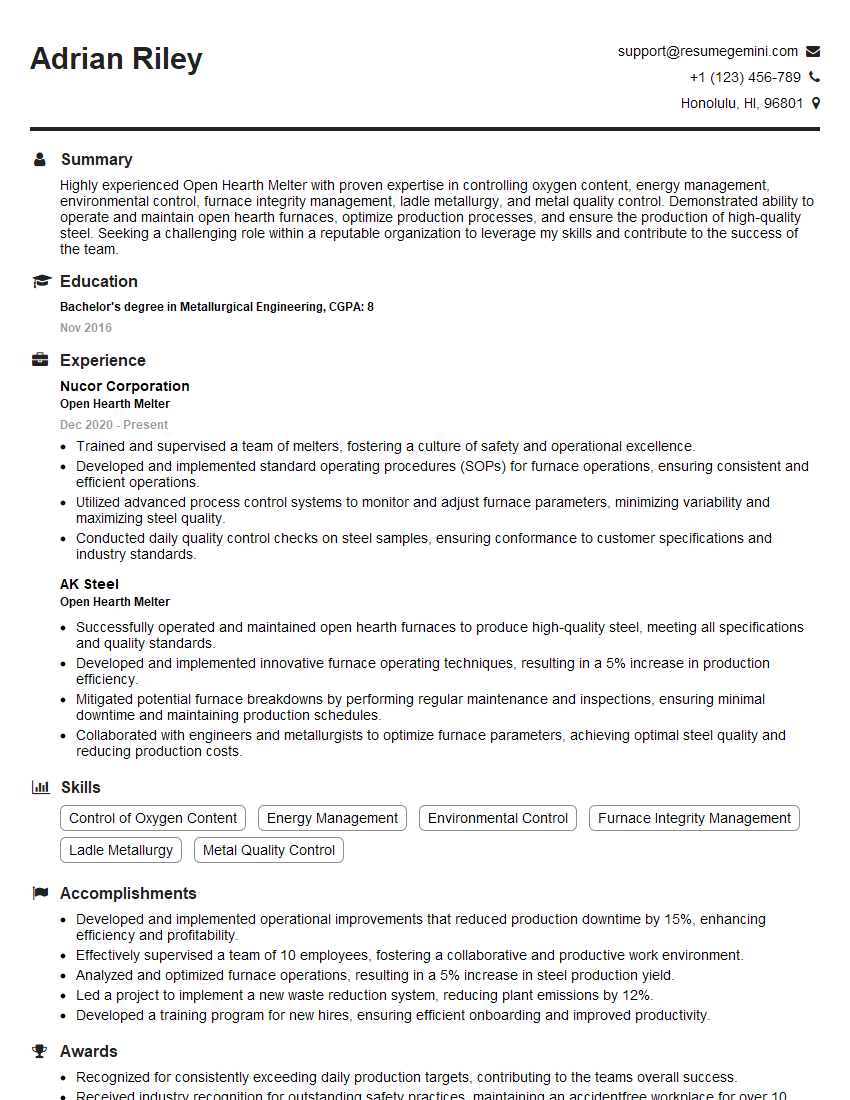

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Open Hearth Melter

1. Explain the role and responsibilities of an Open Hearth Melter?

- Operate, maintain and repair open hearth furnaces including fettling, charging scrap and pig iron into the furnace.

- Control furnace conditions like temperature, oxygen levels, and fuel flow to ensure efficient melting of scrap metal and production of liquid steel.

- Analyze raw materials, adjust furnace conditions, and monitor the melting process to ensure product quality.

- Maintain a clean and safe work environment, and ensure adherence to safety regulations.

- Collaborate with other team members to ensure smooth and efficient operation of the open hearth melting process.

2. Describe your experience in operating and maintaining open hearth furnaces?

- Experience in operating open hearth furnaces for [number] years with [company name].

- Responsible for operating, maintaining, and troubleshooting open hearth furnaces during melting shifts.

- Proficient in performing furnace fettling, refractory repairs, and general maintenance tasks.

- Skilled in identifying and resolving furnace issues to ensure efficient and safe operation.

Experience in furnace operation

Maintenance and repair skills

3. How do you ensure the quality of steel produced in the open hearth furnace?

- Monitor and control furnace conditions, including temperature, oxygen levels, and fuel flow.

- Analyze raw materials and adjust furnace conditions to achieve the desired chemical composition of the steel.

- Take samples of molten steel during the melting process and conduct quality tests to ensure it meets specifications.

- Make adjustments to the melting process based on test results to maintain consistent steel quality.

- Work closely with quality control personnel to ensure compliance with product standards.

4. What are the safety precautions you observe while working in an open hearth melting environment?

- Wear appropriate personal protective equipment (PPE) such as flame-resistant clothing, gloves, and safety glasses.

- Follow established safety procedures and maintain a clean and organized work area.

- Be aware of potential hazards such as molten metal, hot surfaces, and moving machinery.

- Undergo regular safety training and refreshers to stay updated on best practices.

- Report any unsafe conditions or practices to supervisors and take immediate action to mitigate risks.

5. How do you handle unexpected situations or emergencies that may arise during open hearth melting operations?

- Remain calm and assess the situation quickly to identify the root cause of the problem.

- Follow established emergency procedures and alert supervisors promptly.

- Take appropriate actions to contain the situation and prevent further damage or injury.

- Assist in the evacuation of personnel if necessary and provide support to emergency responders.

- Document the incident thoroughly and participate in post-incident investigations to identify areas for improvement.

6. Describe your knowledge of refractory materials used in open hearth furnaces and their importance in the melting process?

- Familiar with various types of refractory materials used in open hearth furnaces, such as silica, magnesia, and alumina.

- Understand the properties and applications of each type of refractory.

- Recognize the importance of refractories in protecting the furnace structure from high temperatures and molten metal.

- Explain how refractories contribute to efficient melting and energy conservation.

- Skilled in inspecting, repairing, and replacing refractory linings to maintain furnace integrity.

- Proficient in fettling techniques to extend refractory life and improve furnace performance.

Types of refractories

Importance of refractories

Refractory maintenance

7. Explain the process of charging the open hearth furnace with scrap and pig iron?

- Describe the sequence of operations involved in charging the furnace, including bucket selection and positioning.

- Explain how different types of scrap and pig iron are charged into the furnace to achieve the desired chemical composition.

- Discuss the importance of proper charging practices for efficient melting and furnace longevity.

- Highlight safety precautions taken during charging operations to prevent accidents and injuries.

8. How do you monitor and control the temperature and oxygen levels in the open hearth furnace?

- Explain the use of thermocouples or other temperature-sensing devices to monitor furnace temperature.

- Describe how fuel flow and air flow are adjusted to maintain the desired temperature range.

- Discuss the importance of controlling oxygen levels in the furnace atmosphere.

- Explain how oxygen probes or other sensors are used to measure oxygen levels.

- Describe how oxygen enrichment or dilution is used to adjust oxygen levels.

Temperature control

Oxygen control

9. How do you ensure that the molten steel produced meets the required specifications?

- Describe the sampling and testing procedures used to analyze the chemical composition of molten steel.

- Explain how the results of these tests are used to make adjustments to the melting process.

- Discuss the importance of adhering to quality control standards and procedures.

- Highlight your experience in working with quality control personnel to maintain product quality.

10. How do you promote teamwork and collaboration in your role as an Open Hearth Melter?

- Emphasize the importance of teamwork in ensuring a safe and efficient melting operation.

- Describe how you communicate effectively with other team members, including melters, chargers, and supervisors.

- Explain how you share knowledge and assist others to improve overall team performance.

- Highlight your ability to work effectively in a fast-paced and demanding environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Open Hearth Melter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Open Hearth Melter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Open Hearth Melters are responsible for operating and maintaining open hearth furnaces, ensuring the production of high-quality steel. Their key responsibilities include:

1. Furnace Operation

Control the operation of open hearth furnaces by adjusting temperature, fuel flow, and oxygen levels.

- Monitor and regulate furnace conditions to optimize steel quality.

- Operate charging machines to load raw materials into the furnace.

2. Steelmaking Process

Control the chemical composition and temperature of molten steel by adding various materials, such as alloys and fluxes.

- Analyze molten steel samples to determine its composition and make adjustments as needed.

- Tap the furnace to release molten steel into ladles for further processing.

3. Equipment Maintenance

Perform routine maintenance on open hearth furnaces and associated equipment to ensure optimal performance.

- Inspect and repair furnace linings, burners, and other components.

- troubleshoot and resolve any equipment malfunctions.

4. Quality Control

Monitor and control the quality of steel produced, ensuring it meets specifications.

- Inspect steel products for defects and ensure compliance with standards.

- Maintain records of furnace operations and steel quality data.

Interview Tips

To impress interviewers and ace your Open Hearth Melter interview, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the company’s history, products, and industry trends. This shows you’re committed and have taken the time to understand their business.

- Check the company website, LinkedIn page, and industry news articles.

- Identify key milestones and recent developments in the company and industry.

2. Highlight Relevant Skills and Experience

Tailor your resume and interview answers to emphasize skills and experience that are directly relevant to the job requirements. Quantify your accomplishments with specific examples and metrics whenever possible.

- Focus on your expertise in furnace operation, steelmaking processes, and equipment maintenance.

- Provide examples of how you have improved steel quality and efficiency in previous roles.

3. Prepare for Technical Questions

Be prepared to answer technical questions about open hearth furnaces, steelmaking processes, and quality control procedures. Review basic concepts and be ready to discuss your understanding of industry best practices.

- Study the principles of open hearth furnace operation and steelmaking.

- Practice solving problems related to furnace control, steel composition, and equipment maintenance.

4. Demonstrate Safety Awareness

Open hearth melters must have a strong commitment to safety. Highlight your safety consciousness and knowledge of industry regulations in your interview.

- Discuss your experience with safety protocols, hazard identification, and risk assessment.

- Emphasize your understanding of the importance of following safety procedures and wearing appropriate protective gear.

5. Show Enthusiasm and Motivation

Convey your passion for the steel industry and your desire to contribute to the company’s success. Express your interest in continuous learning and professional development.

- Explain why you are drawn to the role of Open Hearth Melter and why you believe you are a suitable fit.

- Share your goals and aspirations for career growth within the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Open Hearth Melter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.