Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oxygen Furnace Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

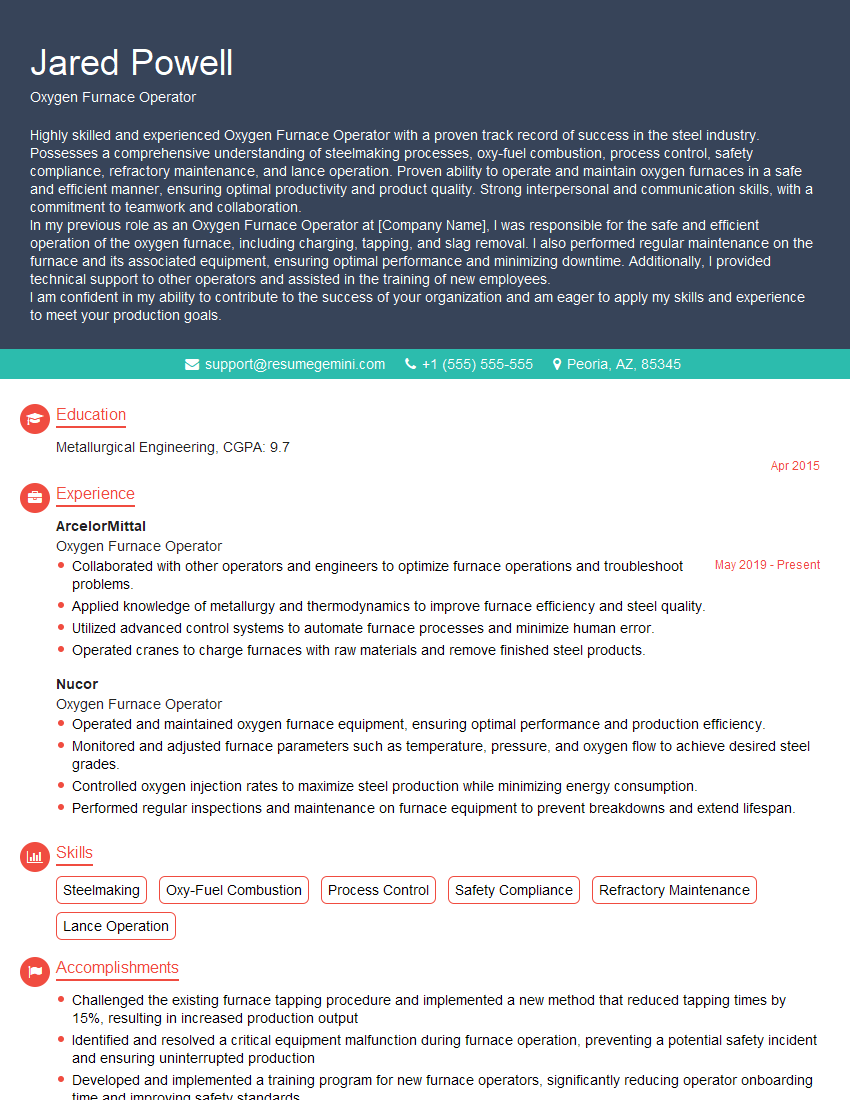

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oxygen Furnace Operator

1. Explain the key responsibilities of an Oxygen Furnace Operator?

As an experienced Oxygen Furnace Operator, my primary responsibilities include:

- Operating and monitoring the oxygen furnace to produce high-quality steel

- Controlling and adjusting furnace temperature, oxygen flow, and other process parameters to optimize production

- Ensuring adherence to safety regulations and protocols

- Troubleshooting and resolving operational issues promptly

- Maintaining records and logs of furnace operations

2. Describe the different types of oxygen furnaces and their applications?

- Basic Oxygen Furnace (BOF): Used for producing carbon steel and is characterized by its fast and efficient operation

- Electric Arc Furnace (EAF): Employs electricity to melt and refine scrap metal, enabling the production of specialty steels and alloys

- Open Hearth Furnace (OHF): An older technology that uses a regenerative system to heat the furnace, primarily used for producing high-carbon and alloy steels

Benefits of BOF:

- High production rates and efficiency

- Produces steel with low sulfur and phosphorus content

- Suitable for large-scale production

Advantages of EAF:

- Versatility in handling different types of scrap

- Lower capital investment compared to BOF

- Environmental friendliness due to lower emissions

3. How do you ensure the production of high-quality steel in an oxygen furnace?

To ensure high-quality steel production, I follow these steps:

- Raw Material Quality Control: Inspecting the quality of iron ore, scrap, and other materials used in the process

- Process Parameter Optimization: Monitoring and adjusting furnace temperature, oxygen flow, and other parameters to achieve optimal conditions

- Slag Management: Controlling the formation and removal of slag to minimize impurities

- Chemical Analysis: Regularly taking samples and analyzing the steel’s chemical composition to ensure it meets specifications

- Defect Prevention: Implementing measures to prevent defects such as inclusions, porosity, and segregation

4. Describe the safety hazards associated with operating an oxygen furnace and how to mitigate them?

Oxygen Furnace Operations involve several safety hazards, including:

- Extreme Heat: Using appropriate protective clothing and heat shields

- Oxygen Exposure: Wearing oxygen-rated respirators and maintaining proper ventilation

- Molten Metal: Following established safety protocols, wearing protective gear, and using remote-controlled equipment

- Electrical Hazards: Ensuring proper grounding and insulation, following lockout/tagout procedures

- Noise: Wearing hearing protection and implementing noise-reducing measures

5. What is the role of instrumentation and control systems in oxygen furnace operations?

Instrumentation and control systems play a crucial role in:

- Process Monitoring: Sensors and gauges provide real-time data on furnace temperature, oxygen flow, and other parameters

- Automatic Control: Controllers adjust furnace conditions based on setpoints and process variables

- Data Logging: Systems record and store operational data for analysis and optimization

- Safety Alarms: Sensors trigger alarms when conditions exceed safe limits

- Optimization: Advanced control algorithms optimize furnace operations, reducing energy consumption and improving quality

6. Explain how you troubleshoot and resolve operational issues in an oxygen furnace?

When troubleshooting operational issues, I follow a systematic approach:

- Identify the Problem: Analyze data, observe furnace behavior, and consult with colleagues

- Determine the Root Cause: Investigate potential causes based on symptoms and experience

- Develop a Solution: Propose and implement corrective actions or modifications

- Monitor and Evaluate: Track the effectiveness of the solution and make adjustments as needed

- Document and Communicate: Record the issue, root cause, solution, and outcome for future reference

7. Describe the importance of preventive maintenance in oxygen furnace operations?

Preventive maintenance is critical for:

- Equipment Uptime: Regular inspections and maintenance prevent breakdowns and unplanned downtime

- Safety: Ensuring equipment is in good condition reduces the risk of accidents

- Quality: Well-maintained equipment contributes to consistent and high-quality steel production

- Cost Savings: Timely maintenance prevents costly repairs and extends equipment life

- Environmental Compliance: Maintaining equipment to prevent leaks and emissions

8. What are the key performance indicators (KPIs) for measuring the efficiency of an oxygen furnace?

- Production Output: Tons of steel produced per hour or shift

- Oxygen Consumption: Cubic meters of oxygen consumed per ton of steel

- Energy Consumption: Kilojoules of energy consumed per ton of steel

- Furnace Availability: Percentage of time the furnace is operational

- Yield: Percentage of raw materials converted into finished steel

9. Explain the use of statistical process control (SPC) in oxygen furnace operations?

SPC involves:

- Data Collection: Gathering data on furnace parameters, steel quality, and other relevant metrics

- Data Analysis: Using statistical techniques to identify patterns, trends, and deviations from standards

- Control Charts: Creating graphical representations of data to monitor process stability and identify areas for improvement

- Corrective Actions: Taking appropriate actions based on SPC analysis to optimize the furnace process and reduce variability

10. Describe your experience working in a team environment and how you contribute to team success?

In team settings, I:

- Collaborate Effectively: Communicate openly, share knowledge, and work together towards common goals

- Provide Support: Assist colleagues, provide technical expertise, and offer assistance when needed

- Take Initiative: Propose ideas, suggest improvements, and actively participate in decision-making

- Resolve Conflicts: Approach conflicts with a positive and constructive attitude, seeking solutions that benefit the team

- Celebrate Success: Recognize and appreciate team achievements, fostering a positive and motivating work environment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oxygen Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oxygen Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oxygen Furnace Operators are responsible for operating and maintaining oxygen furnaces used in the production of steel. Their primary duties involve monitoring and controlling the furnace’s temperature, oxygen flow, and other parameters to ensure the efficient and safe production of molten steel.

1. Furnace Operation

Monitor and control furnace temperature, oxygen flow, and other operating parameters.

- Operate and maintain oxygen furnace equipment, including burners, lances, and other accessories.

- Adjust furnace settings to maintain optimal operating conditions and minimize energy consumption.

2. Process Control

Follow established procedures and specifications to ensure the production of steel with desired properties.

- Monitor and adjust the flow of oxygen, fuel, and other gases into the furnace.

- Control the rate of oxygen injection to achieve the required temperature and oxygen content in the molten steel.

3. Maintenance and Troubleshooting

Perform routine maintenance and repairs on the furnace and associated equipment.

- Identify and troubleshoot operational problems, and take corrective actions to minimize downtime.

- Maintain records of furnace performance and operating conditions.

4. Safety and Environmental Compliance

Adhere to safety regulations and environmental standards related to the operation of oxygen furnaces.

- Follow established safety protocols to prevent accidents and ensure the well-being of personnel.

- Monitor emissions and take measures to minimize environmental impact.

Interview Tips

Preparing for an interview for an Oxygen Furnace Operator position requires a comprehensive approach that encompasses technical knowledge, industry experience, and a strong understanding of the role’s responsibilities. Here are some tips to help you ace the interview:

1. Research the Company and the Position

Before the interview, take the time to research the company’s history, values, and current projects. Familiarize yourself with the specific requirements and expectations of the Oxygen Furnace Operator position.

- Visit the company’s website to gather information about their operations, products, and services.

- Review the job description thoroughly to understand the key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your technical skills and experience in operating and maintaining oxygen furnaces. Provide specific examples of your proficiency in controlling furnace parameters, troubleshooting equipment, and ensuring safe and efficient operations.

- Quantify your accomplishments whenever possible, using metrics to demonstrate your impact on productivity or cost savings.

- Share examples of how you have successfully resolved operational challenges or implemented process improvements.

3. Demonstrate Safety Awareness

Safety is paramount in the operation of oxygen furnaces. Highlight your understanding of safety regulations and your commitment to maintaining a safe work environment. Explain how you prioritize safety in your daily operations.

- Discuss your experience in following safety protocols, using personal protective equipment, and responding to emergencies.

- Emphasize your knowledge of industry best practices and your willingness to participate in safety training and initiatives.

4. Show Enthusiasm and Passion

Express your enthusiasm for the role of Oxygen Furnace Operator and your passion for the steel industry. Explain why you are tertarik in this position and how your skills and experience align with the company’s goals.

- Share your knowledge of current trends and advancements in the field, demonstrating your commitment to continuous learning.

- Articulate your long-term career aspirations and how this position fits into your professional path.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Oxygen Furnace Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!