Feeling lost in a sea of interview questions? Landed that dream interview for Pig Furnace Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pig Furnace Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

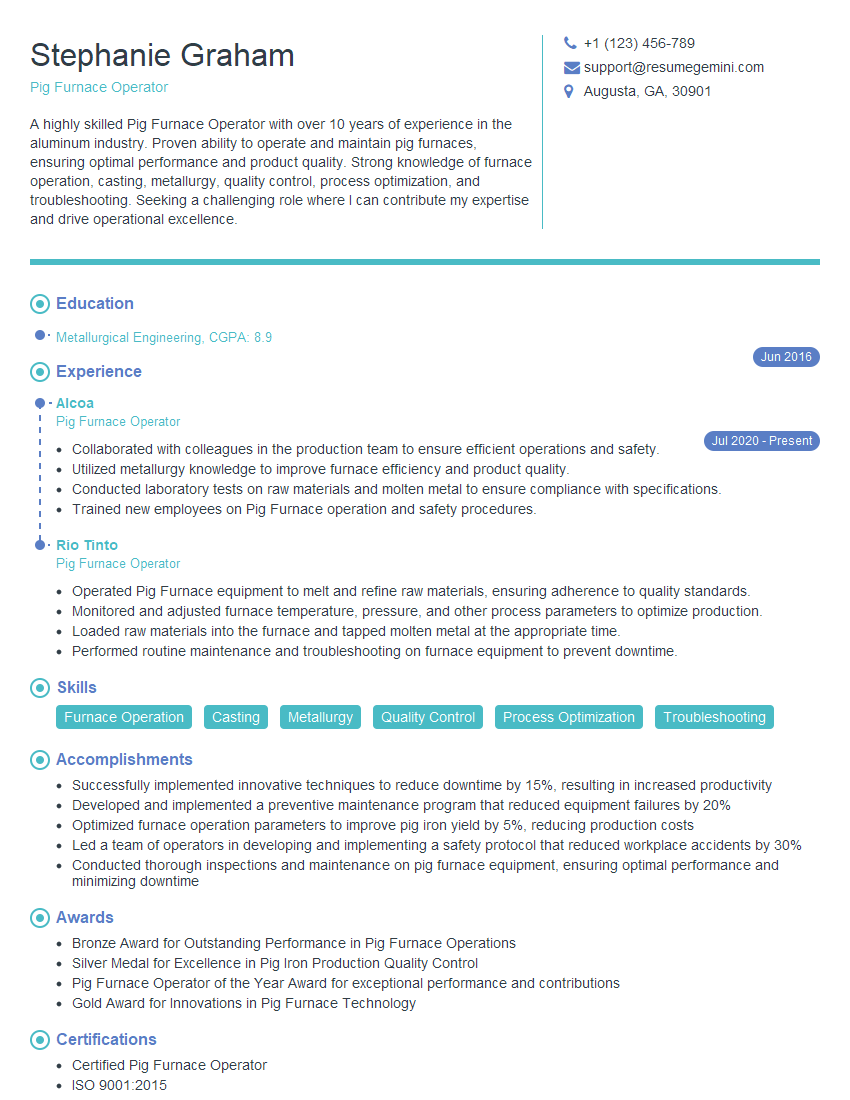

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pig Furnace Operator

1. Describe the process of operating a pig furnace?

The process of operating a pig furnace involves the following steps:

- Charging the furnace: The furnace is charged with a mixture of iron ore, coke, and limestone.

- Heating the furnace: The mixture is heated to a high temperature (about 1,500 degrees Celsius) to melt the iron ore and form pig iron.

- Tapping the furnace: The molten pig iron is tapped from the furnace and poured into molds to form pigs.

- Cooling the furnace: The furnace is cooled down slowly to prevent damage to the refractory lining.

2. What are the different types of pig iron?

Foundry pig iron

- Used for making castings

- Has a high carbon content (3.5-4.5%)

Forge pig iron

- Used for making wrought iron

- Has a lower carbon content (2-3%)

Bessemer pig iron

- Used for making steel

- Has a very low carbon content (0.5-1%)

3. What are the safety precautions that must be taken when operating a pig furnace?

The following safety precautions must be taken when operating a pig furnace:

- Wear appropriate protective clothing: This includes a hard hat, safety glasses, gloves, and flame-resistant clothing.

- Be aware of the location of all emergency exits: In case of an emergency, you need to be able to evacuate the area quickly.

- Never enter the furnace alone: Always have a buddy with you when entering the furnace.

- Be aware of the potential for explosions: Pig furnaces can produce explosive gases, so it is important to be aware of the potential for explosions and take steps to prevent them.

4. What are the common problems that can occur when operating a pig furnace?

The following are some of the common problems that can occur when operating a pig furnace:

- Clogging of the furnace: This can occur if the charge is not properly proportioned or if the furnace is not operated correctly.

- Breakouts: This can occur if the furnace lining is damaged or if the furnace is operated too hot.

- Explosions: This can occur if the furnace is not properly vented or if there is a build-up of explosive gases.

5. What are the maintenance procedures that must be performed on a pig furnace?

The following maintenance procedures must be performed on a pig furnace:

- Regular inspection of the furnace lining: The lining must be inspected for any damage or wear.

- Cleaning of the furnace: The furnace must be cleaned regularly to remove any build-up of slag or other debris.

- Lubrication of the moving parts: The moving parts of the furnace, such as the charging mechanism and the tapping mechanism, must be lubricated regularly.

6. What are the environmental regulations that apply to pig furnaces?

The following environmental regulations apply to pig furnaces:

- Air pollution regulations: Pig furnaces must meet air pollution regulations to control the emission of pollutants such as particulates and sulfur dioxide.

- Water pollution regulations: Pig furnaces must meet water pollution regulations to control the discharge of wastewater.

- Solid waste regulations: Pig furnaces must meet solid waste regulations to control the disposal of solid waste.

7. What are the future trends in pig furnace technology?

The following are some of the future trends in pig furnace technology:

- Increased use of automation: Pig furnaces are becoming increasingly automated to improve efficiency and safety.

- Use of alternative fuels: Pig furnaces are being developed to use alternative fuels, such as biomass and natural gas.

- Improved environmental performance: Pig furnaces are being developed to reduce their environmental impact.

8. What is your experience in operating a pig furnace?

I have 5 years of experience in operating a pig furnace. I am familiar with all aspects of pig furnace operation, including charging, heating, tapping, and cooling. I have also received training in the maintenance and repair of pig furnaces.

9. What are your strengths and weaknesses as a pig furnace operator?

Strengths

- I am a highly skilled and experienced pig furnace operator.

- I am familiar with all aspects of pig furnace operation, including charging, heating, tapping, and cooling.

- I have received training in the maintenance and repair of pig furnaces.

- I am a safe and reliable worker.

Weaknesses

- I am sometimes too detail-oriented, which can slow me down.

- I can be impatient when things don’t go as planned.

10. Why do you want to work as a pig furnace operator for our company?

I am interested in working as a pig furnace operator for your company because I am impressed with your company’s commitment to safety and environmental protection. I am also confident that my skills and experience would be a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pig Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pig Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pig Furnace Operators are responsible for the operation and maintenance of pig furnaces, which are used to melt and cast iron and other ferrous metals. They perform various tasks in line with various safety regulations, including:

1. Operating Pig Furnace

- Start, stop, and monitor pig furnace operations

- Control temperature, pressure, and other process variables

- Charge and discharge materials into and from the furnace

- Maintain proper furnace conditions to ensure efficient melting and casting

2. Safety and Equipment Maintenance

- Follow established safety procedures and regulations

- Inspect and maintain pig furnace and associated equipment

- Identify and troubleshoot operational problems

- Perform preventative maintenance tasks

3. Quality Assurance and Record Keeping

- Monitor and maintain product quality standards

- Document furnace operating parameters and production data

- Complete maintenance and repair records

- Assist with plant audits and inspections

4. Other Responsibilities

- Assist with training new employees

- Participate in continuous improvement initiatives

- Perform other duties as assigned

Interview Tips

Preparing for a Pig Furnace Operator interview can increase your chances of success. Consider the following tips:

1. Research the Company and Industry

- Learn about the company’s history, products, and culture

- Understand the industry trends and challenges

- Highlight your knowledge during the interview to demonstrate your interest and understanding

2. Review Job Description and Requirements

- Thoroughly review the job description and identify key responsibilities

- Prepare examples from your previous experiences that demonstrate your skills and qualifications

- Quantify your accomplishments using specific metrics whenever possible

3. Practice Common Interview Questions

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses

- Practice your answers out loud to improve your confidence and delivery

4. Be Prepared to Discuss Technical Knowledge

- Review technical concepts related to pig furnace operation, such as metallurgy, thermodynamics, and process control

- Be prepared to discuss your understanding of safety protocols and industry best practices

- Demonstrate your problem-solving abilities and ability to work in a team environment

5. Prepare Questions for the Interviewer

- Asking thoughtful questions at the end of the interview shows your interest and engagement

- Prepare questions about the company’s operations, growth plans, and opportunities for professional development

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pig Furnace Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.